|

HMT710S - Hydrometallurgy 314 - 1st Opp - June 2022 |

|

1 Page 1 |

▲back to top |

nAmlBIA unlVERSITY

OF SCIEnCE Ano

FACULTY OF ENGINEERING AND SPATIAL SCIENCES

DEPARTMENT OF MINING AND PROCESSENGNEERING

QUALIFICATION : BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 0SBEMT

LEVEL: 7

COURSE CODE: HMT 710S

COURSE NAME: HYDROMETALLURGY 314

SESSION: JUNE 2022

DURATION: 2 HOURS

PAPER: THEORY

MARKS: 60

FIRST OPPORTUNITY QUESTION PAPER

EXAMINER(S) Mr. Bernard Sililo

MODERATOR: Dr. Theresa Coetsee

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

|

3 Page 3 |

▲back to top |

Question 1

The typical way of operating a solvent extraction process is to run a continuous counter-

current multi-stage system. In these operations, organic substances such as Kerosine are

used.

1.1 Why does copper sulphate dissolve in water and kerosene does not?

(2)

1.2 Where and how is this difference in 1.1 best utilised in hydrometallurgical processes?

(3)

1.3 Instead of precipitation, it is proposed that solvent extraction can be used in the

purification of the solution. If given the general formula of the extractant to be RH:

a) Write down the reaction that represents the loading of copper on the solvent. (1)

b) Explain the importance of pH in the solvent extraction process.

(2)

1.4 The concept of solvent extraction has become an integral part of copper recovery.

Briefly explain why solvent extraction as a way of purifying solution has an advantage

over precipitation in this process.

(5)

Question 2

[15]

2.1 In a traditional Roast - Leach - Electrowin (RLE) process, iron is the main impurity.

Goethite process is one way of removing iron from leach solution. The process is

conducted at elevated temperatures and in solutions with fairly dilute concentrations

of iron.

a) Why would you say goethite process is better compared to jarosite and hematite

processes?

(2)

b) Explain the importance of elevated temperatures and dilute solutions.

(4)

c) Given that oxygen forms the supporting cathodic reaction, give your opinion on the

effect of operating conditions on this process.

(2)

2.2 You are given a process stream from the zinc sulphate leach system that contains 20g/l

Fe that has to be precipitated as goethite and the solution flowrate is 1.5 m3 per hour.

If 90% of iron is precipitated, calculate the mass of goethite produced per hour. Molar

masses: Fe = 56; 0 = 16; H = 1.

(7)

|

4 Page 4 |

▲back to top |

|

5 Page 5 |

▲back to top |

Question 3

[10]

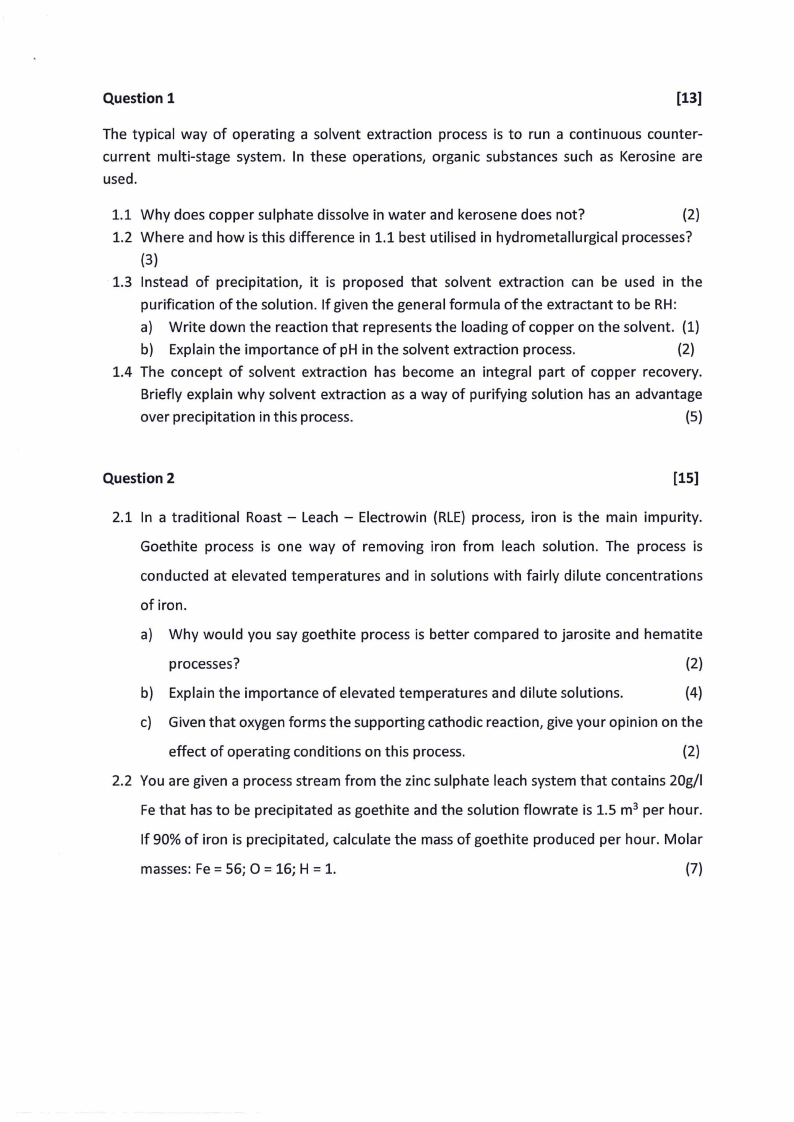

Gold may be recovered from cyanide solutions by use of the zinc-cementation process.

3.1 Make use of the Eh-pH diagram below for drawing a suitable sketch to explain the

electrochemical principles of the process.

(5)

3.2 Explain what would happen should the concentration of cyanide ions increase and

decrease respectively.

(5)

1.0

- 1.0

OS.28>

--Au.._

Zn(CN)i-

Zn

- 2.0-~~..__...__.____,__.__.__.___.___.___.___.......J

0

4

6

8 10 12 14

pH

Figure 15.2.Potential-pHequilibriumdiagramillustratingfeaturesof theAu-CN-H,O and Zn-CN-H20systems

at 2S'C. (CN"llllal= 10-3 mol 1·1, [Au(CN=J2to]-4mol 1·1, (Zn2·J3.,1 = 10-3 mol 1·1.

|

6 Page 6 |

▲back to top |

|

7 Page 7 |

▲back to top |

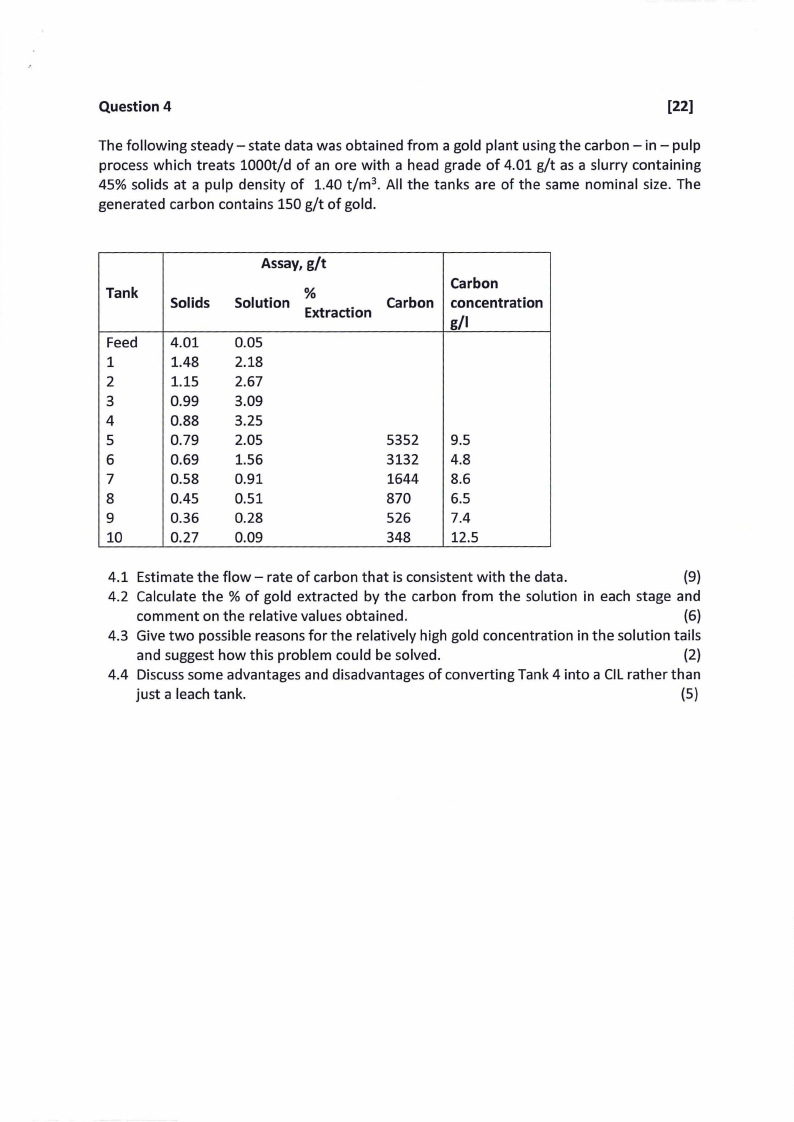

Question 4

[22]

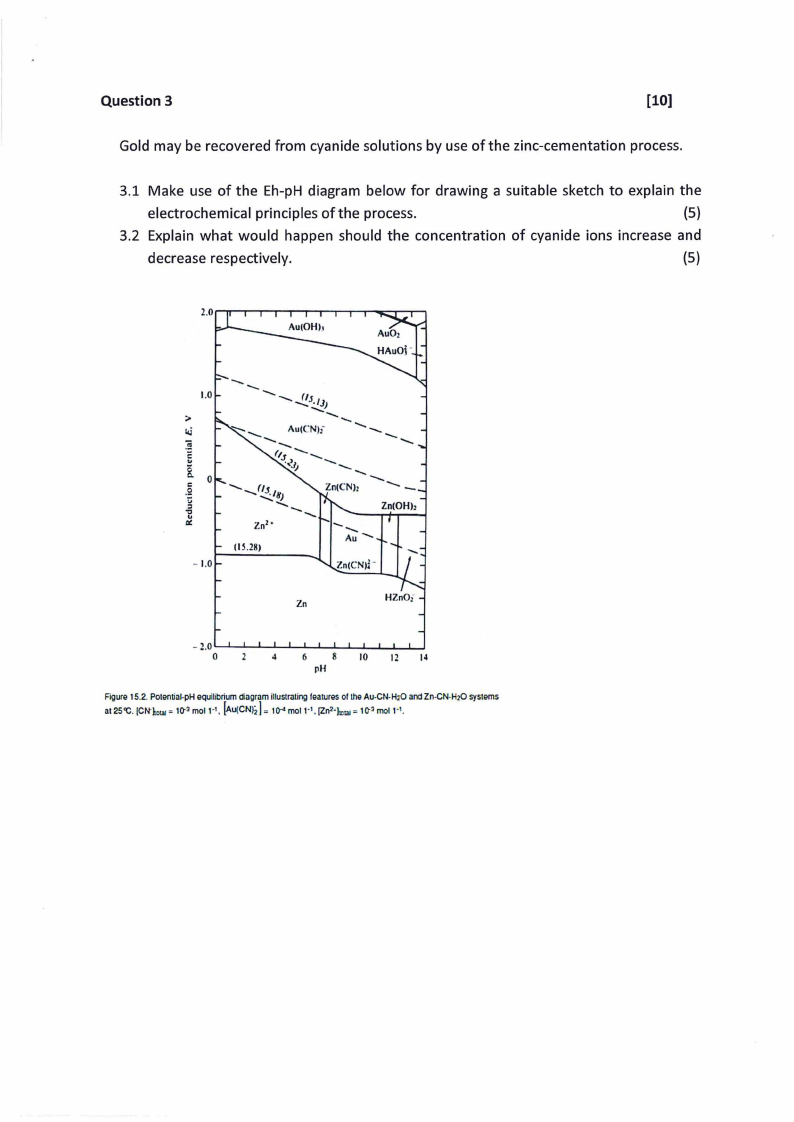

The following steady- state data was obtained from a gold plant using the carbon - in - pulp

process which treats 1000t/d of an ore with a head grade of 4.01 g/t as a slurry containing

45% solids at a pulp density of 1.40 t/m 3• All the tanks are of the same nominal size. The

generated carbon contains 150 g/t of gold.

Tank

Feed

1

2

3

4

5

6

7

8

9

10

Solids

4.01

1.48

1.15

0.99

0.88

0.79

0.69

0.58

0.45

0.36

0.27

Assay, g/t

Solution

%

Extraction

0.05

2.18

2.67

3.09

3.25

2.05

1.56

0.91

0.51

0.28

0.09

Carbon

5352

3132

1644

870

526

348

Carbon

concentration

g/1

9.5

4.8

8.6

6.5

7.4

12.5

4.1 Estimate the flow - rate of carbon that is consistent with the data.

(9)

4.2 Calculate the % of gold extracted by the carbon from the solution in each stage and

comment on the relative values obtained.

(6)

4.3 Give two possible reasons for the relatively high gold concentration in the solution tails

and suggest how this problem could be solved.

(2)

4.4 Discuss some advantages and disadvantages of converting Tank 4 into a CILrather than

just a leach tank.

(5)

|

8 Page 8 |

▲back to top |