|

UDM711S - Underground Mining 315 - 1st OPP - June 2023 |

|

1 Page 1 |

▲back to top |

n Am I B I A u n IVE Rs I TY

OF SCIEnCE Ano TECHno LOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CIVIL, MINING, AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING (BEng) - MINING ENGINEERING

QUALIFICATION CODE: 08BMIN-05

LEVEL: 7

COURSE CODE: UDM711S

COURSE NAME: UNDERGROUND MINING 315

SESSION: JUNE 2023

DURATION: 2 HOURS

PAPER: THEORY AND CALCULATIONS

MARKS: 100

EXAMINER

FIRST OPPORTUNITY QUESTION PAPER

Mr. Tshivute lipinge

MODERATOR:

Mr. Ruben Mwalwange

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat, and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

1

|

2 Page 2 |

▲back to top |

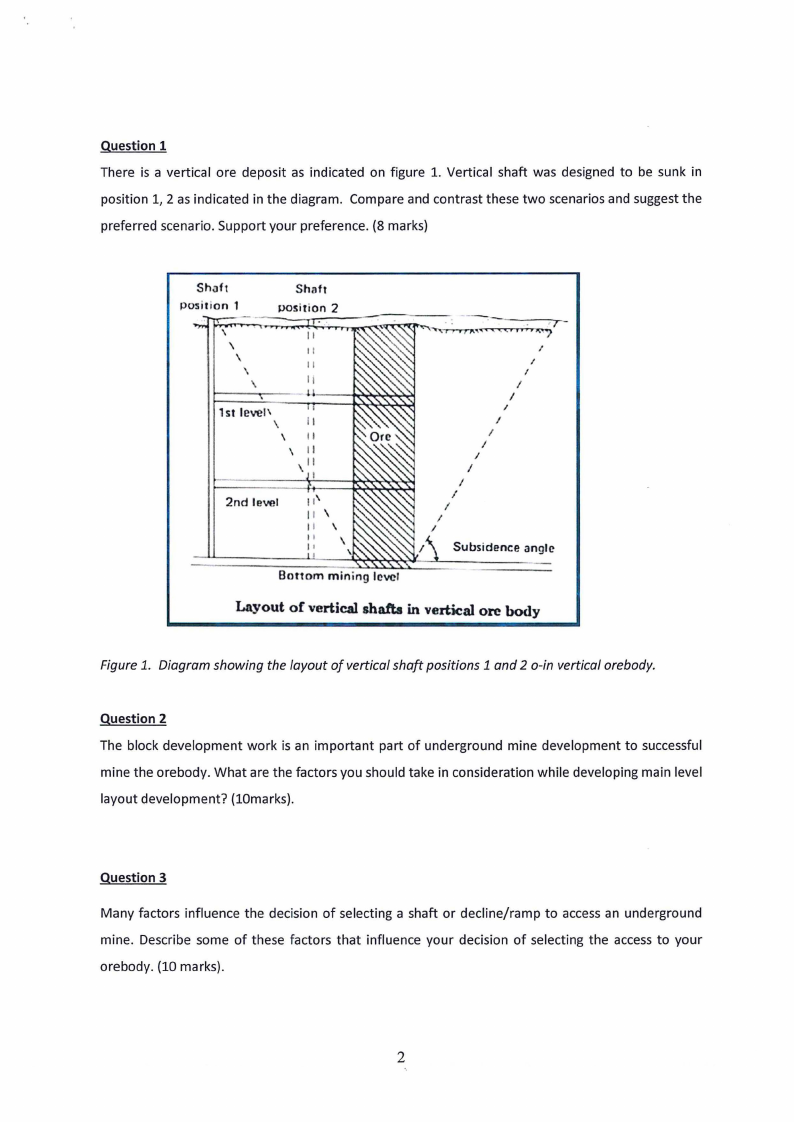

Question 1

There is a vertical ore deposit as indicated on figure 1. Vertical shaft was designed to be sunk in

position 1, 2 as indicated in the diagram. Compare and contrast these two scenarios and suggest the

preferred scenario. Support your preference. (8 marks)

Shaft

Shnft

position 1

position 2

'-'-:-',..,...-, -~--r-,_-.-..,..-..~.-,Jcr-J-.,.;_..-,.._:,-Tl-,...-«.-~--:----.

r.

11

"'"-~,,

-------

.-''"

";' ""'?r-

\\

ht level\\

\\

'' \\ \\ 11

\\ II

I

2nd level I,,

11 \\

,,11

II

-----=-----~~I ~::..:_

Bottom mining level

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1 \\ Subsidence angle

__

Layout of vertical shafts in vertical ore body

Figure 1. Diagram showing the layout of vertical shaft positions 1 and 2 o-in vertical orebody.

Question 2

The block development work is an important part of underground mine development to successful

mine the orebody. What are the factors you should take in consideration while developing main level

layout development? (lOmarks).

Question 3

Many factors influence the decision of selecting a shaft or decline/ramp to access an underground

mine. Describe some of these factors that influence your decision of selecting the access to your

orebody. (10 marks).

2

|

3 Page 3 |

▲back to top |

Question 4

Given the following data for the design of friction sheave hoists; calculate the total cycle time and

skip capacity and its weight.

Two balanced skips, tower mounted hoists

Production rate= 8000 tons/day

Working time = 3 shift/day

Shaft distance = 1200 m

Headframe height= 35m

Skip load = 0.67 live load

Load time= dump time= 6 sec

Hoisting speed = 12.5 m/sec

Acceleration = retardation = 2.3 m/s 2

(12 marks)

Question 5

As a Mining Engineer you are required to develop a haulage crosscut in the orebody, and the stope

access raise inside the mining block. The daily production tons are 4 500 tons, total ore tons in the

stope are 55 000 tons, the length of the stope is 50 m, the dip of the ore deposit is 60°, height of

haulage crosscut is 5.5 m. Compute the following parameters:

a) Haulage crosscut advance per day. (2 marks)

b) The length of the stope access raise. (2 marks)

c) The stope access raise advance per day. (2 marks)

Question 6

As a mine planning engineer, describe the six dimensions that are vital in characterising the work

conditions of your equipment selection? (12 marks).

Question 7

A mine has a zinc deposit that is being mined with a target of 20 000 tonnes of ore per month, with

an open stope mining method. The stope is on average 15m wide and inter-level spacing of 45m.

Longitudinal mining is being executed with the length of the stope being around 150m long. Ringsare

planned with a burden of 1.Sm and spacing 2.m. If blasting is done once every week to meet

production and specific gravity of 2.5 can be applied.

a) Draw the section of the mining method (4 marks)

b) Compute stope Volume (2 marks)

c) Compute the stope, and the ring tonnages (3 marks)

d) The number of rings that must be blasted every week (3 marks)

e) How long does the stope last before it is mined out? (3 marks)

f) The cross cut to the loading bay is 1 km long and it takes 10 minutes cycle time for LHD with

3.5 m• bucket to travel. A 20-tonne truck takes 30 minutes cycle time to haul material to

3

|

4 Page 4 |

▲back to top |

surface. Would the two pieces equipment meet the production target if you have three shifts

of 8 hours? (12 marks).

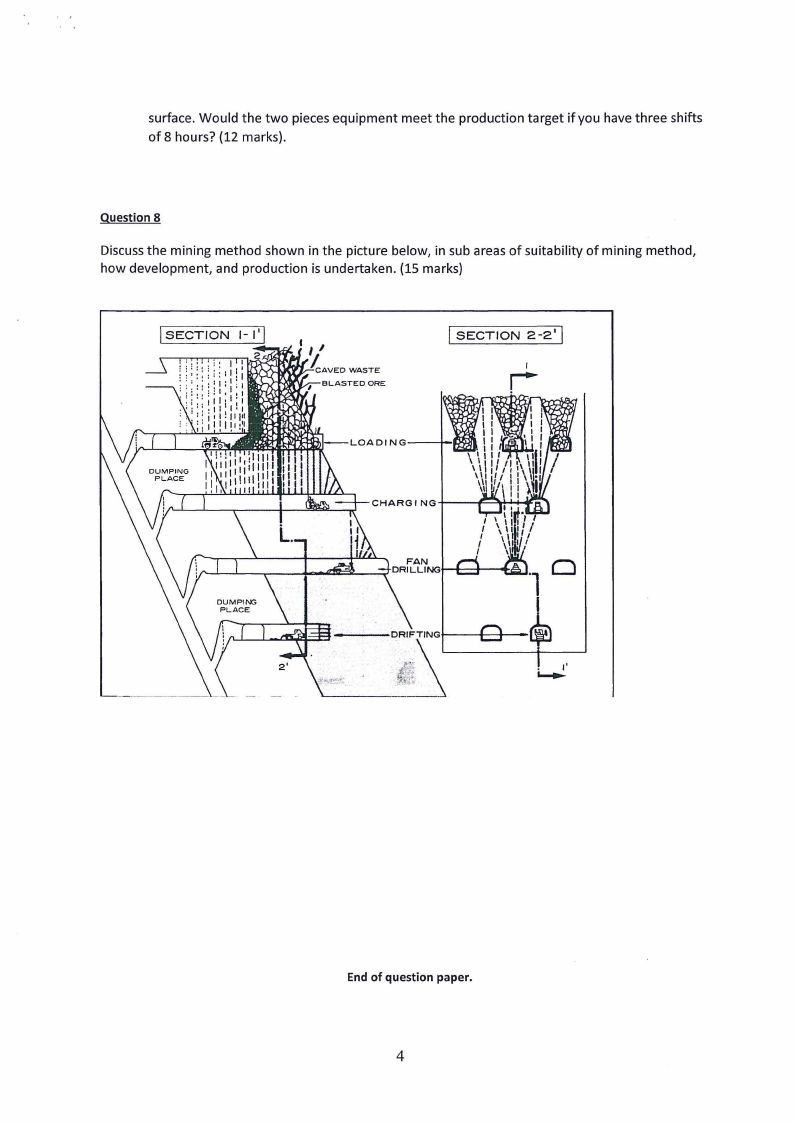

Question 8

Discussthe mining method shown in the picture below, in sub areas of suitability of mining method,

how development, and production is undertaken. (15 marks)

JSECTION

!!

/ SECTION 2-2' j

rI

·10

t------t--t--~

End of question paper.

4