|

MMY820S - Mechanical Metallurgy - 1st OPP - JUN 2023 |

|

1 Page 1 |

▲back to top |

nAmlBIA UnlVERSITY

OF SCIEnCE Ano TECHn OLOGY

FACULTY OF ENGINEERING AND SPATIAL SCIENCES

DEPARTMENTOF MECHANICAL,MINING AND PROCESSENGINEERING

QUALIFICATION:BACHELOROF ENGINEERINGIN METALLURGY

QUALIFICATIONCODE: 0BBMET

LEVEL:8

COURSECODE: MMY820S

COURSENAME: MECHANICALMETALLURGY

SESSION:June 2023

DURATION: 3 HOURS

PAPER:THEORY

MARKS: 100

EXAMINER(S)

FIRST OPPORTUNITY QUESTION PAPER

Prof. Sofya Mitropolskaya

MODERATOR:

Prof JosiasVan der Merwe

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each questions are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

THIS QUESTIONPAPERCONSISTSOF 6 PAGES(Including this front page)

|

2 Page 2 |

▲back to top |

Question1 [25 marks]

(a) Table Ql shows typical data for strength of copper alloys: pure copper, bronze (a solid

solution of tin or beryllium in copper) and brass (a solid solution of zinc in copper). Rank

the strengthening mechanisms (as indicated in the table) in order of effectiveness.

[2]

Table Ql. Strengthof a selectionof copperalloys.

Alloy

Process route Main strengthening mechanism

Yield

strength

(MPa)

Pure Cu

Cast

None

35

Bronze: Cu + 10% Sn Cast

Solid solution strengthening

200

Brass: Cu + 30% Zn Cast

Solid solution strengthening

90

Brass: Cu + 30% Zn Cold-rolled

Solid solution strengthening+

400

dislocation strengthening

Bronze: Cu + 2% Be Heat treated Precipitation strengthening

1000

(b) The yield strength oy of plain carbon steel is dependent on the grain sized, and the relation

can be described by the equation:

+ k~ Uy= <J0

where Oo and k are material constants. The yield strength of a plain carbon steel is 622 MPa

for a grain size of 180 µm and 663 MPa for a grain size of 22 µm.

(i) Calculate the yield strength of the steel for a grain size of llµm.

[10]

(ii) Explain briefly the physical significance of the Oa constant.

[1]

(iii) What methods can you recommend to ensure grain refinement of a plain carbon steel?

[2]

(c) The critical strength 6c of a plain carbon steel equals 900 MPa. Ultrasonic non-

destructive inspection of an axle made of this steel has revealed a microcrack

S0µm long (2a = S0µm). Is it safe to operate such an axel? Estimate with the aid

of Griffith's criterion:

where o-cis the critical stress required for propagation of the brittle crack;

ys is the energy of the new surface area per unit of area;

Eis Young's modulus

a is a half-length of a critical crack that will propagate spontaneously;

1t = 3,14;

if the following parameters apply:

I Iron

Oc, MPa

I 900

Ys, J/m 2

1,2

E, GPa

205

[10]

2

|

3 Page 3 |

▲back to top |

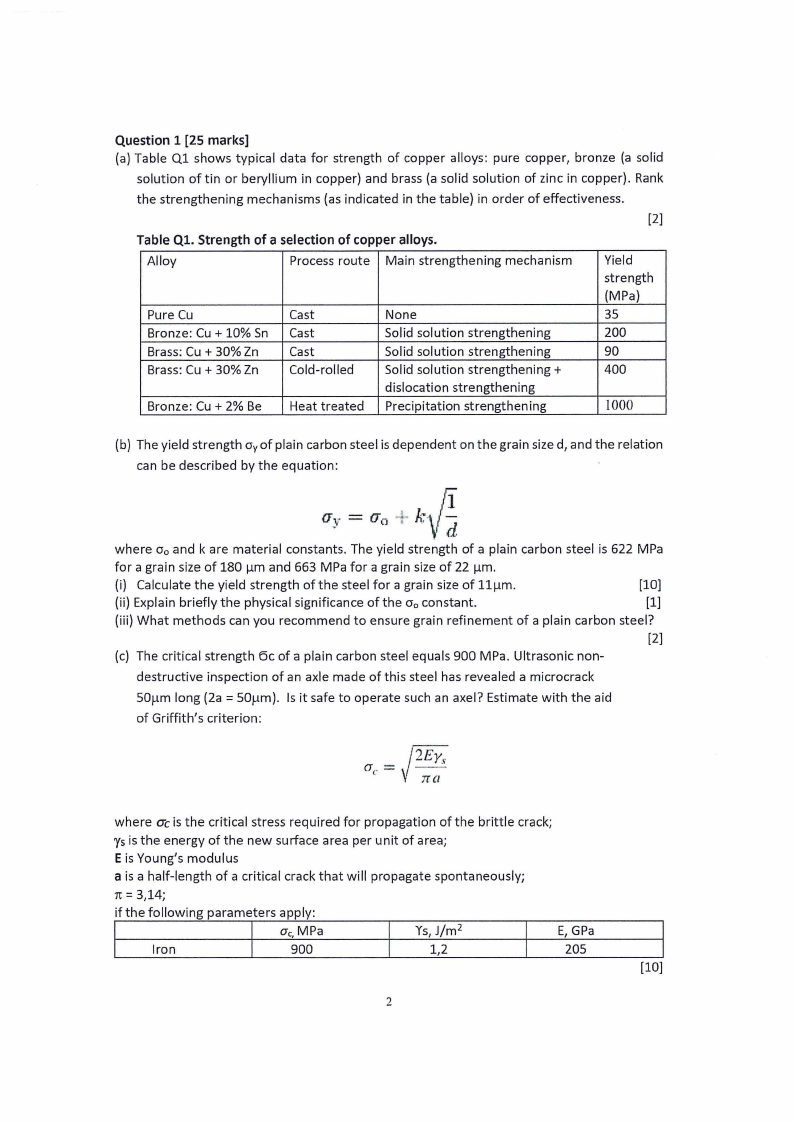

Question2 [25 marks]

(a) Figure Q2-1 reveals stress-strain curves for a selection of engineering alloys. Use the

diagrams to find:

(i) The metal with the lowest yield strength. [1]

(ii) The metal with the highest tensile strength [1]

(iii) The metal with the lowest ductility [1]

800

,.......,_700

ro

Q..

600

........500

C

t) 400

(/)

-(/)

(.I.) ..

300

Cl) 200

100

Drawn

-brass

Annealed

brass

/

Annealed/

copper

00

10 20 30 40

50 60

Strainen (%)

Figure Q2-1. Stress-strain curves for a selection of engineering alloys.

(b) Figure Q2-2 shows an S-N curve for AISI 4340 steel after heat treatment.

(i) What is the endurance limit for this steel? [3]

(ii) If cycled for 100 cycles at an amplitude of 1200 MPa, will it fail? [2]

(iii) If cycled for 100 000 cycles at the amplitude of 1000 MPa, will it fail?[2]

1500

1400

e,a"'.. 1300

1200

c" 1100

oi

"O

1000

a-~. 900

E

<II 800

(/)

(/)

700

in 600

500

400

102

4340 low-alloy steel,

quenched and tempered 425 •c

Stress ratio R "' -1

1Q3

1Q4

1Q5

106

107

1Q8

Number of cycles to failure, N1

Figure Q2-2. Fatigue behaviour of low-alloy steel 4340.

3

|

4 Page 4 |

▲back to top |

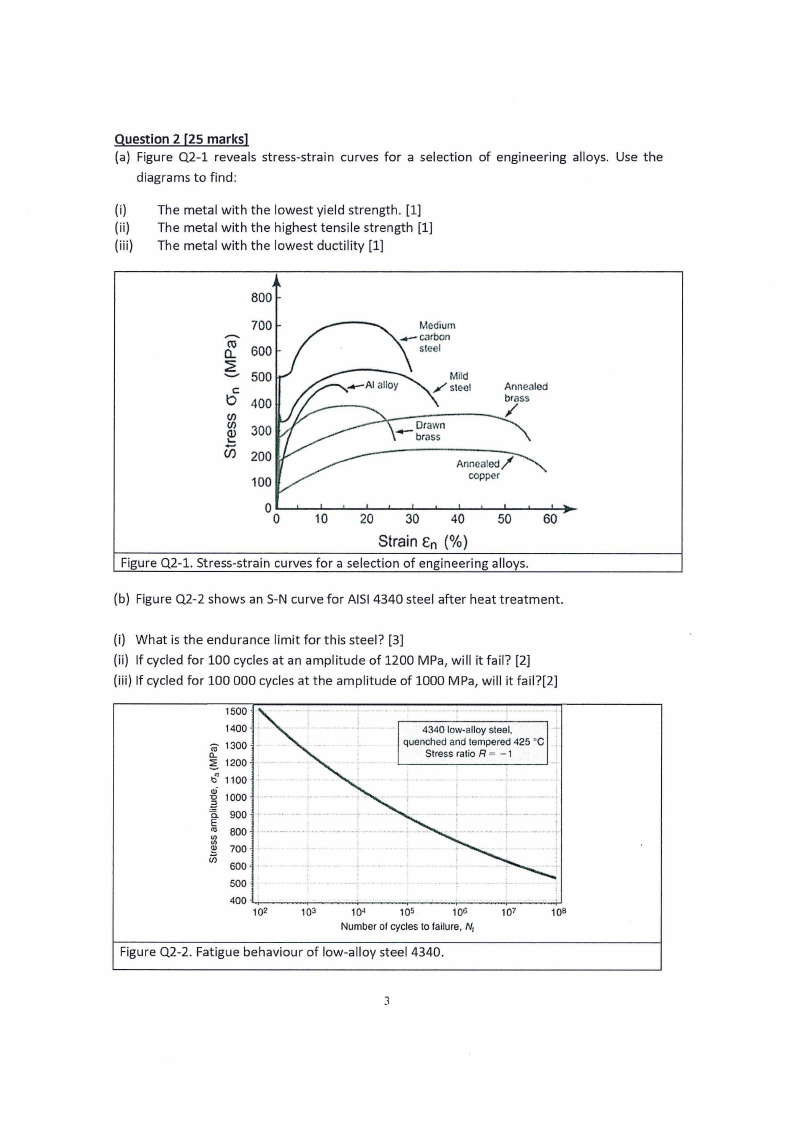

(c) A newly developed vaccine against COVID-19 is to be transported and stored under

extremely low temperature (minus 70 °q. The vaccine will be administered with the aid

of refrigerating containers. Fig. Q2-3 features the Charpy impact energy of three

candidate steel grades (A, B, and C) in a wide temperature range, from +80°C to -80°C.

(i) Which steel grade should be selected for the refrigerating containers manufacturing (the

operating temperature is as low as minus 70 °C): steel A or steel B or steel C? Briefly

provide reasons.

(10]

(ii) Speculate upon the type of steel suitable to meet the target (lattice type, alloying

system).

[5]

-.

-o'

.QcJ

0

JS 50

">-'

""'

C

<10

QJ

t,

"a.' 20

/

/

/

/

.§

/

>a.

__./

"''-

.ur:;

0

-80

-40

o

Temperature,

•40

0c

.A

B

C

..-ao

Figure Q2-3. Charpy impact energy as a function of

temperature for candidate steel grades A, B, and C

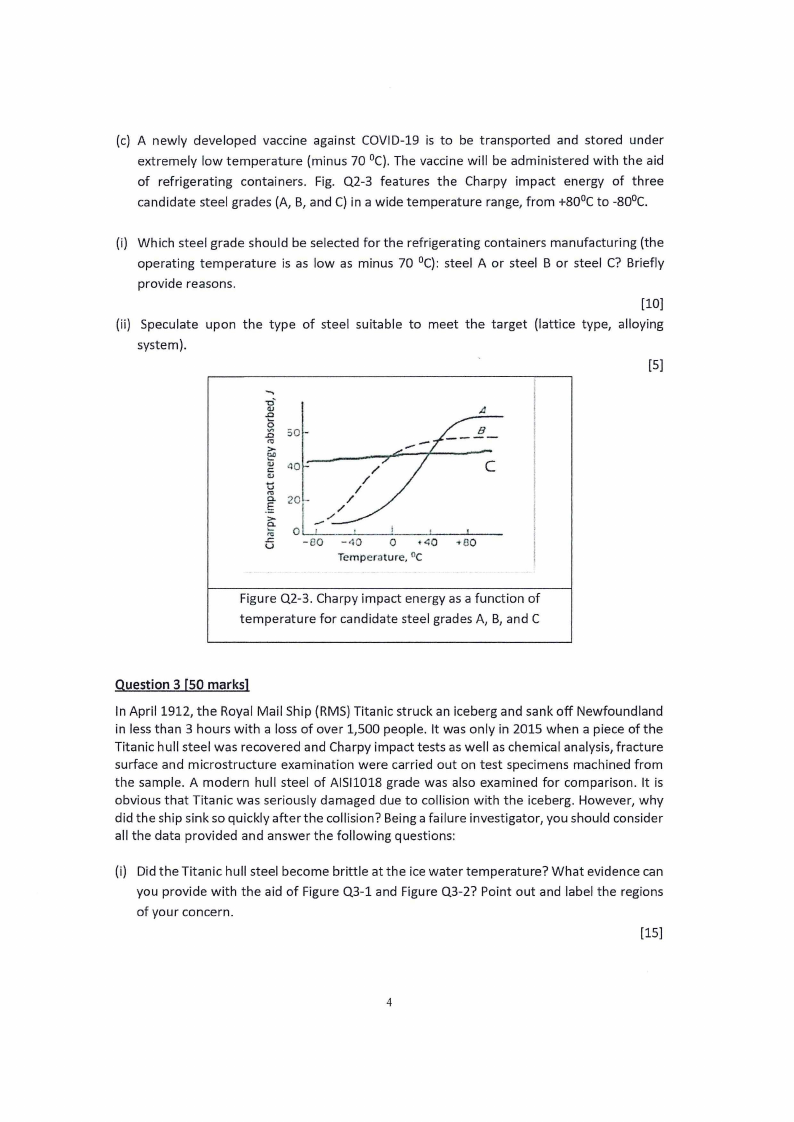

Question3 [SOmarks)

In April 1912, the Royal Mail Ship (RMS) Titanic struck an iceberg and sank off Newfoundland

in less than 3 hours with a loss of over 1,500 people. It was only in 2015 when a piece of the

Titanic hull steel was recovered and Charpy impact tests as well as chemical analysis, fracture

surface and microstructure examination were carried out on test specimens machined from

the sample. A modern hull steel of A!SI1018 grade was also examined for comparison. It is

obvious that Titanic was seriously damaged due to collision with the iceberg. However, why

did the ship sink so quickly after the collision? Being a failure investigator, you should consider

all the data provided and answer the following questions:

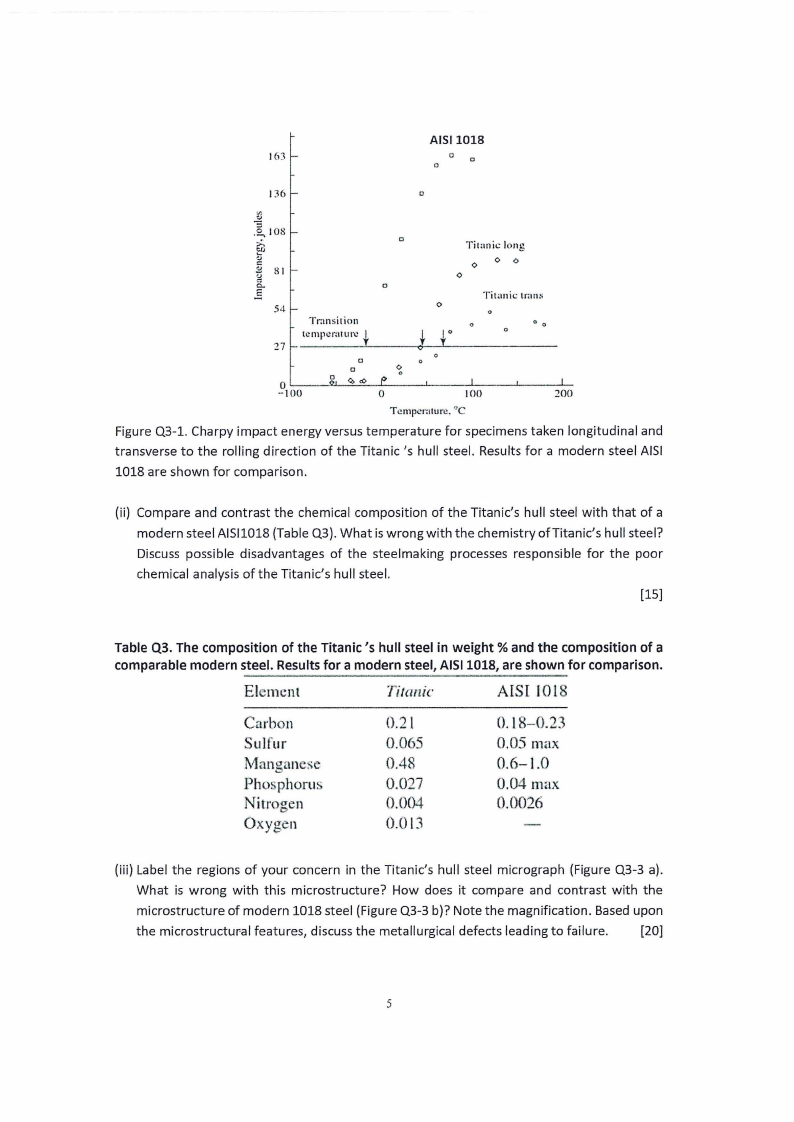

(i) Did the Titanic hull steel become brittle at the ice water temperature? What evidence can

you provide with the aid of Figure Q3-1 and Figure Q3-2? Point out and label the regions

of your concern.

[15]

4

|

5 Page 5 |

▲back to top |

AISI 1018

163

a

C

C

136

"

",£5 . 108

;,:._

l:!l

u-iai:i:.. 81

0

0

54

t Tr:rnsition

tcmper:1turc

27

0

··100

C

C

0

0

D <c <O

0

Titanic long

0

0

00

0

t I•

0

0

Titanic trans

0

0

0

00

100

200

T<!mpcrature. ~c

Figure Q3-l. Charpy impact energy versus temperature for specimens taken longitudinal and

transverse to the rolling direction of the Titanic's hull steel. Results for a modern steel AISI

1018 are shown for comparison.

(ii) Compare and contrast the chemical composition of the Titanic's hull steel with that of a

modern steel AISl1018 (Table Q3). What is wrong with the chemistry ofTitanic's hull steel?

Discuss possible disadvantages of the steelmaking processes responsible for the poor

chemical analysis of the Titanic's hull steel.

[15]

Table Q3. The compositionof the Titanic's hull steel in weight% and the compositionof a

comparablemodernsteel. Resultsfor a modernsteel,AISI1018, are shownfor comparison.

Element

TitaHic

AISI 10l8

Carbon

Sulfur

Manganese

Phosphorus

Nitrogen

Oxygen

0.21

0.065

0.48

0.027

0.004

0.013

0. 18-0.23

0.05 max

0.6-1.0

0.04 max

0.0026

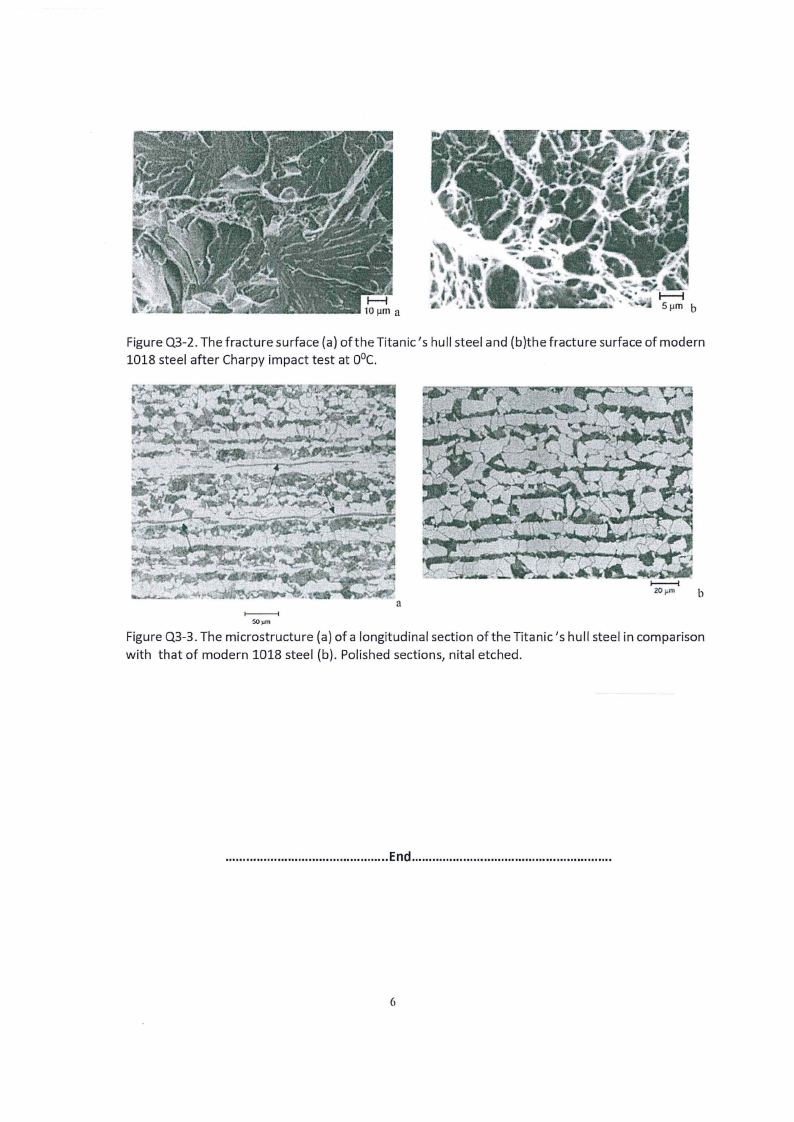

{iii) Label the regions of your concern in the Titanic's hull steel micrograph (Figure Q3-3 a).

What is wrong with this microstructure? How does it compare and contrast with the

microstructure of modern 1018 steel {Figure Q3-3 b)? Note the magnification. Based upon

the microstructural features, discuss the metallurgical defects leading to failure.

[20]

5

|

6 Page 6 |

▲back to top |

Figure Q3-2. The fracture surface (a) of the Titanic's hull steel and (b)the fracture surface of modern

1018 steel after Charpy impact test at o0c.

1------l

20"'" b

1--------<

SOµm

Figure Q3-3. The microstructure (a) of a longitudinal section of the Titanic's hull steel in comparison

with that of modern 1018 steel (b). Polished sections, nital etched .

...............................................End.........................................................

6