|

HTM811S - Heat Treatment of Metals 414 - 2nd Opp - June 2023 |

|

1 Page 1 |

▲back to top |

nAmI BI AunIVER s ITY

OF SCIEn CE Ano TECHn OLOGY

FACULTYOF ENGINEERINGAND SPATIALSCIENCES

DEPARTMENT OF CIVIL, MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 08BEMT

LEVEL: 8

COURSE CODE: HTM811S

COURSE NAME: HEAT TREATMENT OF METALS 414

SESSION: June 2023

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

SECONDOPPORTUNITY QUESTION PAPER

Mrs Jaquiline T. Kurasha

MODERATOR:

Prof Josias Van der Merwe

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each questions are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examination paper.

2. Non-programmable calculator.

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

Question 1 (25 marks]

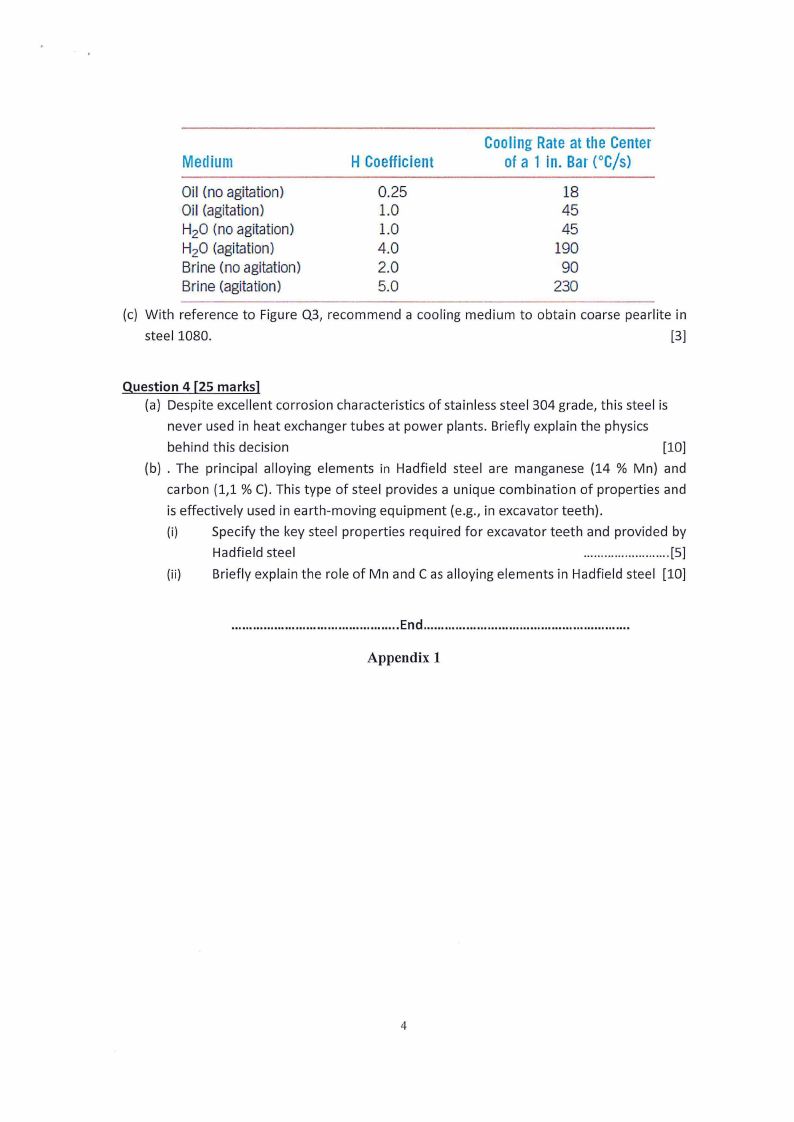

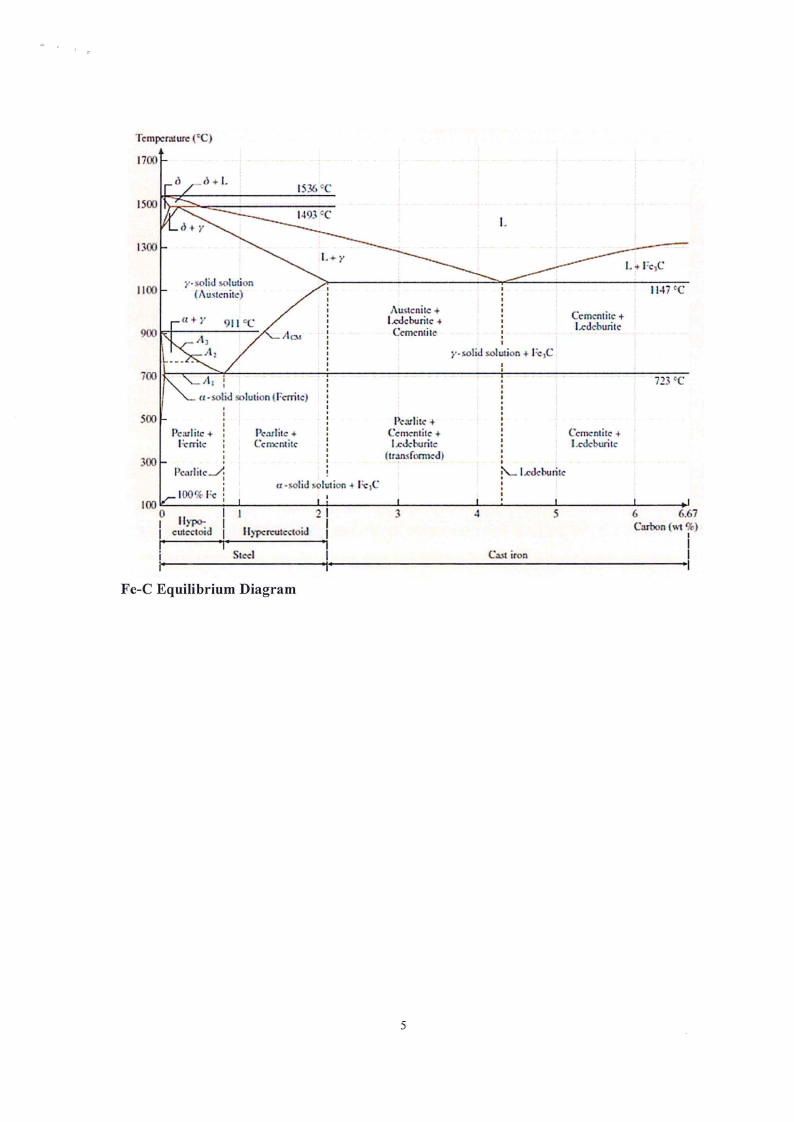

(a) Upon slow cooling a plain carbon steel 1080 contains 100% pearlite at room temperature.

Since pearlite is a eutectoid mixture of ferrite and cementite, calculate the weight

percentage of cementite and the weight percentage of ferrite in pearlite in a typical steel

1080. Make use of the Lever Rule and the Fe-C Equilibrium Diagram (see Appendix 1) [16]

(b) A Lab technician prepared three samples of steels: (i) a hypoeutectoid plain carbon steel

after slow cooling; (ii) a hypereutectoid plain carbon steel after slow cooling under the same

conditions; (iii) an austenitic stainless steel. Unfortunately, he failed to label the samples

properly. Suggest simple yet effective method to identify which sample is made of which

steel, with the aid of a magnet and a hardness tester. Please note that metallographic

microscope is out of operation.

[9]

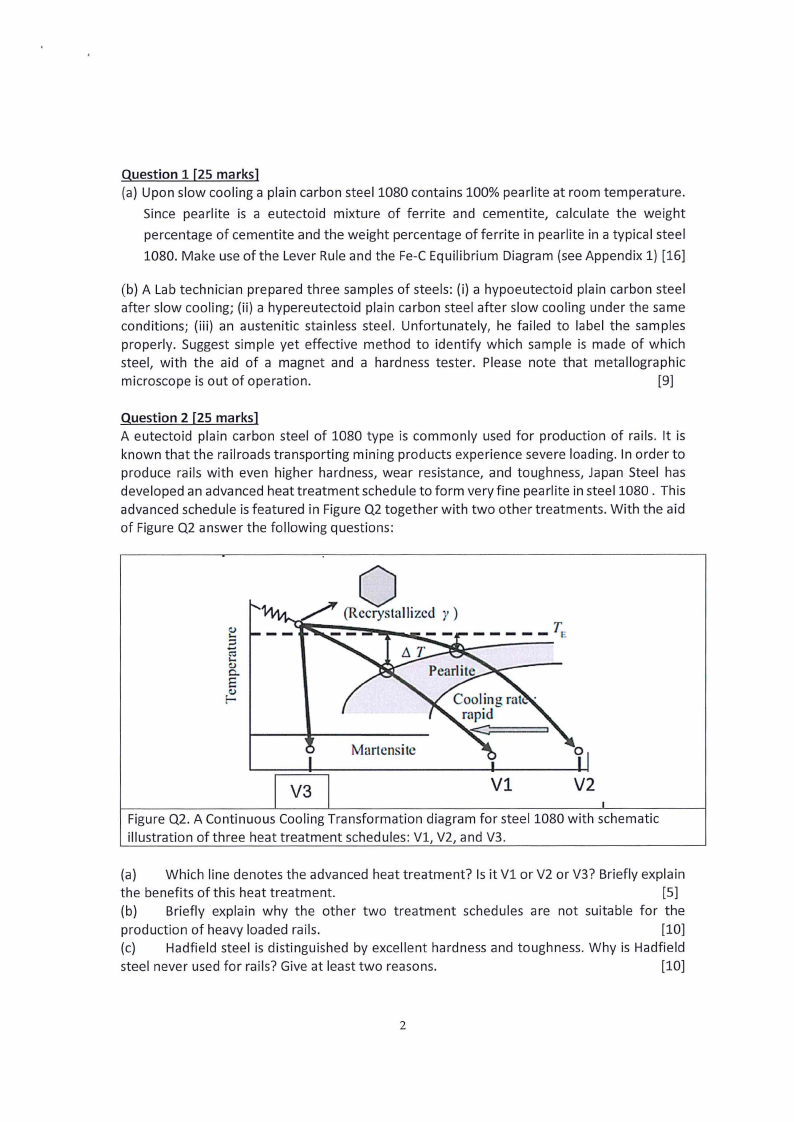

Question 2 (25 marks]

A eutectoid plain carbon steel of 1080 type is commonly used for production of rails. It is

known that the railroads transporting mining products experience severe loading. In order to

produce rails with even higher hardness, wear resistance, and toughness, Japan Steel has

developed an advanced heat treatment schedule to form very fine pearlite in steel 1080. This

advanced schedule is featured in Figure Q2 together with two other treatments. With the aid

of Figure Q2 answer the following questions:

2

C..;) ..

i:.i

0..

E

Martcnsitc

V3

V1

V2

Figure Q2. A Continuous Cooling Transformation diagram for steel 1080 with schematic

illustration of three heat treatment schedules: Vl, V2, and V3.

(a) Which line denotes the advanced heat treatment? Is it Vl or V2 or V3? Briefly explain

the benefits of this heat treatment.

[5]

(b) Briefly explain why the other two treatment schedules are not suitable for the

production of heavy loaded rails.

[10]

(c) Hadfield steel is distinguished by excellent hardness and toughness. Why is Hadfield

steel never used for rails? Give at least two reasons.

[10]

2

|

3 Page 3 |

▲back to top |

Question 3 [25 marks]

(a) Typical media used for quenching include air, brine (10% salt in water), water, and oil.

(ii) Rank the four media in order of the cooling rate from fastest to slowest. [5]

(iii) During quenching in liquid media, very often either the part being cooled, or

the bath is agitated. Explain why.

[5]

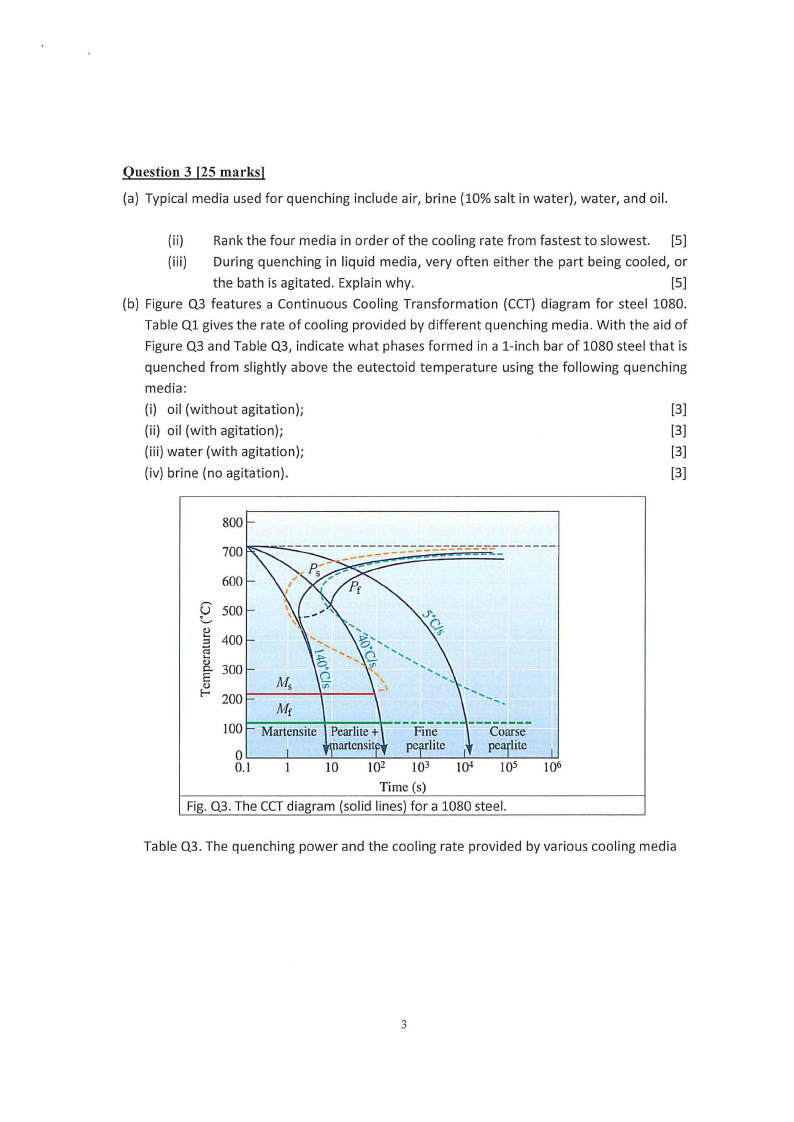

(b) Figure Q3 features a Continuous Cooling Transformation (CCT) diagram for steel 1080.

Table Q1 gives the rate of cooling provided by different quenching media. With the aid of

Figure Q3 and Table Q3, indicate what phases formed in a 1-inch bar of 1080 steel that is

quenched from slightly above the eutectoid temperature using the following quenching

media:

(i) oil (without agitation);

[3]

(ii) oil (with agitation);

[3]

(iii) water (with agitation);

[3]

(iv) brine (no agitation).

[3]

800

700

600

E soo

e::i 400

g_ 300

§

f-<

200 ------M--s-1

Mf

100 Martensite

00.~1 -~--~-~--1~0--~-1~0-2-~

Coarse

pea lite

104

1Q6

Time (s)

Fig. Q3. The CCTdiagram (solid lines) for a 1080 steel.

Table Q3. The quenching power and the cooling rate provided by various cooling media

3

|

4 Page 4 |

▲back to top |

Medium

H Coefficient

CoolingRateat theCenter

ofa 1 in. Bar(°C/s)

Oil (no agitation)

0.25

18

Oil (agitation)

1.0

45

H2O (no agitation)

1.0

45

H2O (agitation)

4.0

190

Brine (no agitation)

2.0

90

Brine (agitation)

5.0

230

(c) With reference to Figure Q3, recommend a cooling medium to obtain coarse pearlite in

steel 1080.

[3]

Question 4 [25 marks]

(a) Despite excellent corrosion characteristics of stainless steel 304 grade, this steel is

never used in heat exchanger tubes at power plants. Briefly explain the physics

behind this decision

[10]

(b) . The principal alloying elements in Hadfield steel are manganese (14 % Mn} and

carbon (1,1 % C). This type of steel provides a unique combination of properties and

is effectively used in earth-moving equipment (e.g., in excavator teeth).

(i) Specify the key steel properties required for excavator teeth and provided by

Hadfield steel

........................(.5)

(ii) Briefly explain the role of Mn and C as alloying elements in Hadfield steel [10]

............................................... End ......................................................... .

Appendix 1

4

|

5 Page 5 |

▲back to top |

Tcmpernture (0 C)

1700

1536cc

1500

L

1300

1100

:,--solid solution

(i\\w1cni1c)

i\\ustcnilc +

l.cdcburirc +

Cc:mc:n1i1c

;,-solid solution + Fc1C

Ccmrntilc +

Lcdcburilc

11-17'C

t\\ I

a-solid solution (ferrite)

5

Pc:ulirc +

Fc:rrilc

300

Pc.11li1.c.../.

I

100

0

I

I

llypo-

culccloid

Pc.:ulirc:+

Ccm::ntirc

P.:-:1.ditc+

Cc:mC'ntitc+

l..cdc:buritc

(t~fom,rd)

a -solid solution-+ Fc:1C

21

3

llypc:milcctoid

I

I

723 "C

Cc:mcntilc:+

l..cdcburitc

l.cdcburilc

5

C:ul iron

6

6.67

Camon (,,1 %)

I

I

I

Fe-C Equilibrium Diagram

5