|

OLM611C-OPERATION LOGISTICS MANG-1ST OPP JUNE 2024 |

|

1 Page 1 |

▲back to top |

nAmlBIA UnlVERSITY

OF SCIEnCE TECHnOLOGY

FACULTY OF COMMERCE, HUMAN SCIENCES AND EDUCATION

HAROLD PUPKEWITZ GRADUATE SCHOOL OF BUSINESS

QUALIFICATION: DIPLOMA IN BUSINESS PROCESS MANAGEMENT

QUALIFICATION CODE: 0GDBPM

LEVEL: 6

COURSE CODE: OLM611 C

COURSE NAME: OPERATIONAL LOGISTICS

MANAGEMENT

SESSION: JUNE 2024

DURATION: 3 HOURS

PAPER: PAPER 1

MARKS: 100

FIRST OPPORTUNITY EXAMINATION - QUESTION PAPER

EXAMINER(S) Dr. Gloria Tshoopara

MODERATOR: Ms. Hilma Nuuyandja

INSTRUCTIONS

1. Answer ALL the questions.

2. Write clearly and neatly.

3. Number the answers clearly.

PERMISSIBLE MATERIALS

1. Examination paper

2. Examination script

THIS QUESTION PAPER CONSISTS OF 7 PAGES (INCLUDING THIS FRONT PAGE)

1

|

2 Page 2 |

▲back to top |

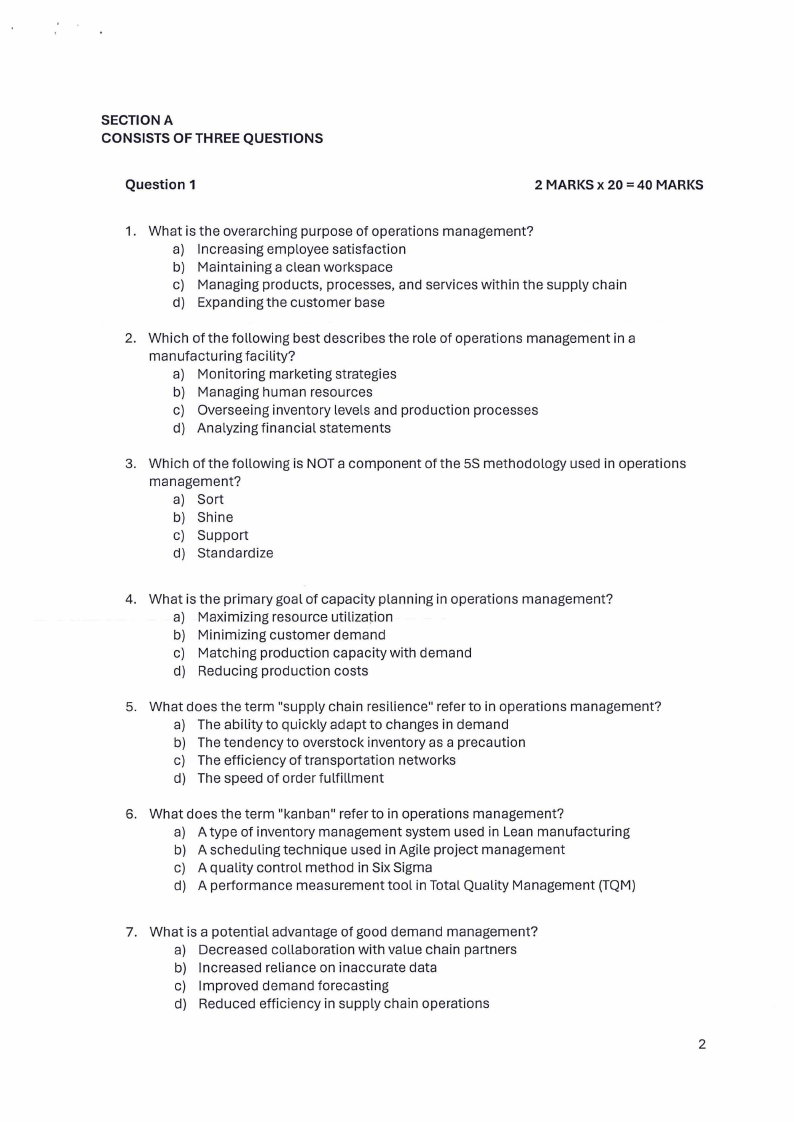

SECTION A

CONSISTS OF THREE QUESTIONS

Question 1

2 MARKS x 20 = 40 MARKS

1. What is the overarching purpose of operations management?

a) Increasing employee satisfaction

b) Maintaining a clean workspace

c) Managing products, processes, and services within the supply chain

d) Expanding the customer base

2. Which of the following best describes the role of operations management in a

manufacturing facility?

a) Monitoring marketing strategies

b) Managing human resources

c) Overseeing inventory levels and production processes

d) Analyzing financial statements

3. Which of the following is NOT a component of the 5S methodology used in operations

management?

a) Sort

b) Shine

c) Support

d) Standardize

4. What is the primary goal of capacity planning in operations management?

a) Maximizing resource utilization

b) Minimizing customer demand

c) Matching production capacity with demand

d) Reducing production costs

5. What does the term "supply chain resilience" refer to in operations management?

a) The ability to quickly adapt to changes in demand

b) The tendency to overstock inventory as a precaution

c) The efficiency of transportation networks

d) The speed of order fulfillment

6. What does the term "kanban" refer to in operations management?

a) A type of inventory management system used in Lean manufacturing

b) A scheduling technique used in Agile project management

c) A quality control method in Six Sigma

d) A performance measurement tool in Total Quality Management (TQM)

7. What is a potential advantage of good demand management?

a) Decreased collaboration with value chain partners

b) Increased reliance on inaccurate data

c) Improved demand forecasting

d) Reduced efficiency in supply chain operations

2

|

3 Page 3 |

▲back to top |

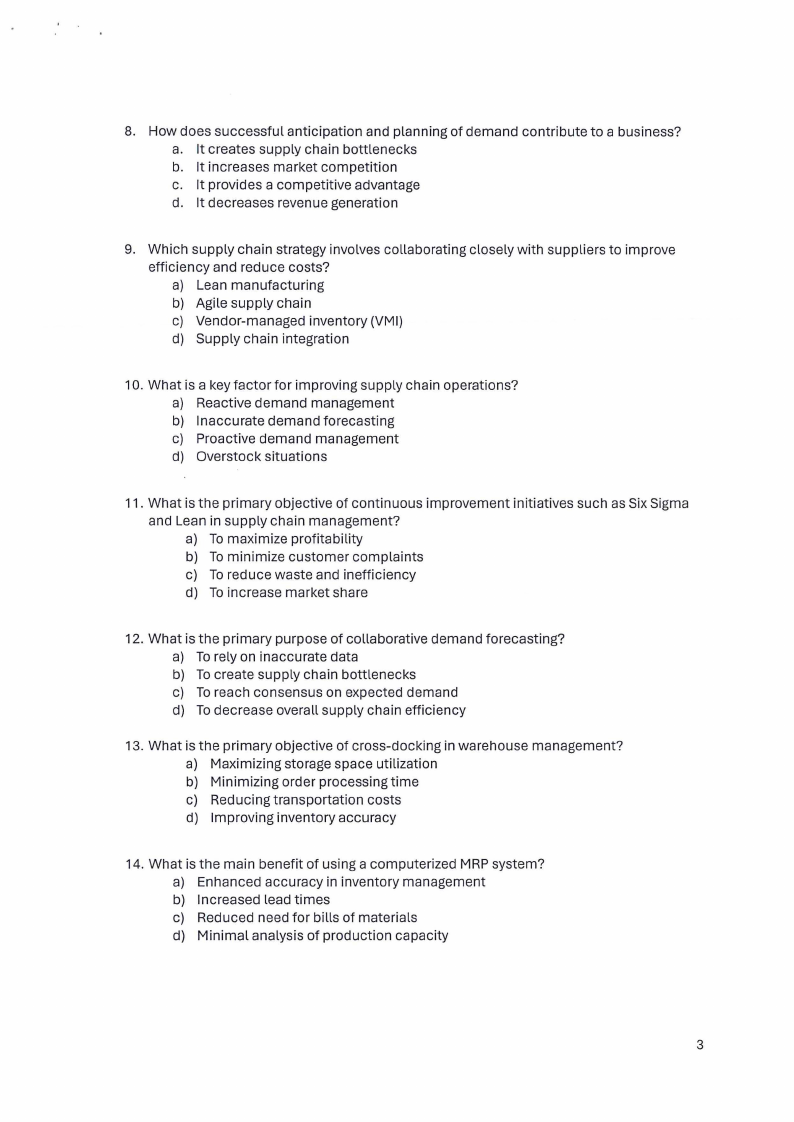

8. How does successful anticipation and planning of demand contribute to a business?

a. It creates supply chain bottlenecks

b. It increases market competition

c. It provides a competitive advantage

d. It decreases revenue generation

9. Which supply chain strategy involves collaborating closely with suppliers to improve

efficiency and reduce costs?

a) Lean manufacturing

b) Agile supply chain

c) Vendor-managed inventory (VMI)

d) Supply chain integration

10. What is a key factor for improving supply chain operations?

a) Reactive demand management

b) Inaccurate demand forecasting

c) Proactive demand management

d) Overstock situations

11. What is the primary objective of continuous improvement initiatives such as Six Sigma

and Lean in supply chain management?

a) To maximize profitability

b) To minimize customer complaints

c) To reduce waste and inefficiency

d) To increase market share

12. What is the primary purpose of collaborative demand forecasting?

a) To rely on inaccurate data

b) To create supply chain bottlenecks

c) To reach consensus on expected demand

d) To decrease overall supply chain efficiency

13. What is the primary objective of cross-docking in warehouse management?

a) Maximizing storage space utilization

b) Minimizing order processing time

c) Reducing transportation costs

d) Improving inventory accuracy

14. What is the main benefit of using a computerized MRP system?

a) Enhanced accuracy in inventory management

b) Increased lead times

c) Reduced need for bills of materials

d) Minimal analysis of production capacity

3

|

4 Page 4 |

▲back to top |

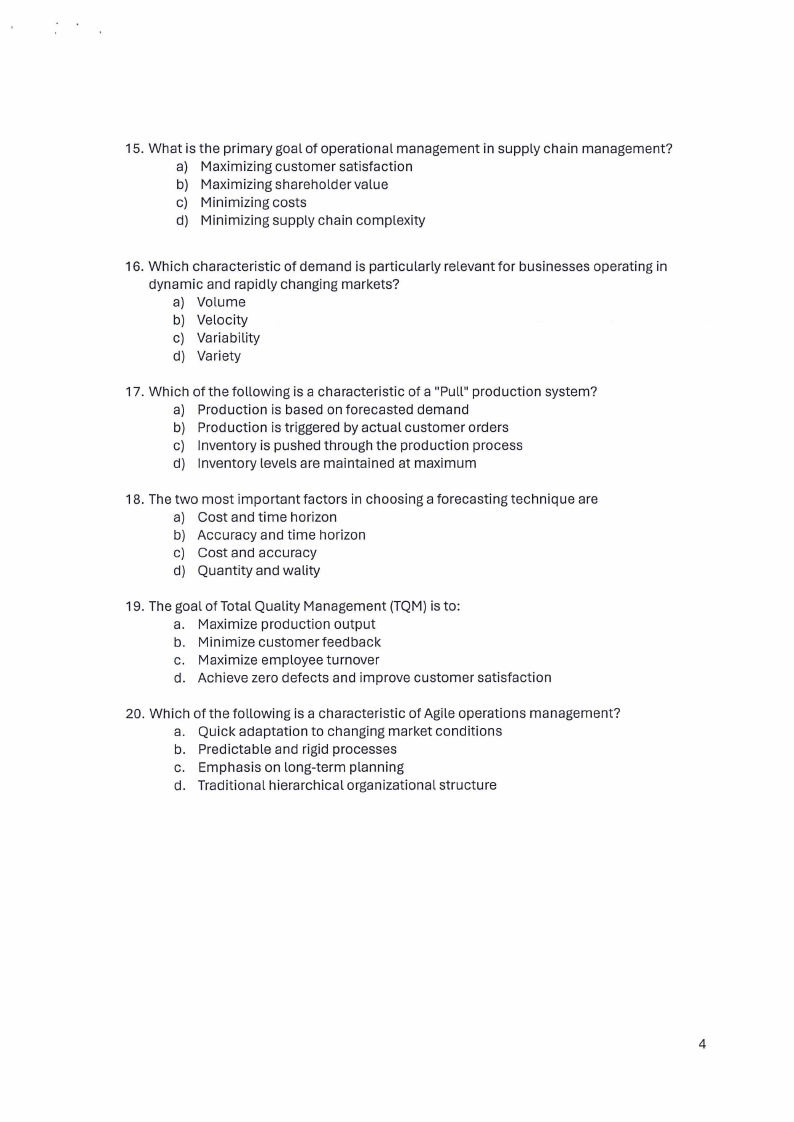

15. What is the primary goal of operational management in supply chain management?

a) Maximizing customer satisfaction

b) Maximizing shareholder value

c) Minimizing costs

d) Minimizing supply chain complexity

16. Which characteristic of demand is particularly relevant for businesses operating in

dynamic and rapidly changing markets?

a) Volume

b) Velocity

c) Variability

d) Variety

17. Which of the following is a characteristic of a "Pull" production system?

a) Production is based on forecasted demand

b) Production is triggered by actual customer orders

c) Inventory is pushed through the production process

d) Inventory levels are maintained at maximum

18. The two most important factors in choosing a forecasting technique are

a) Cost and time horizon

b) Accuracy and time horizon

c) Cost and accuracy

d) Quantity and wality

19. The goal of Total Quality Management (TQM)is to:

a. Maximize production output

b. Minimize customer feedback

c. Maximize employee turnover

d. Achieve zero defects and improve customer satisfaction

20. Which of the following is a characteristic of Agile operations management?

a. Quick adaptation to changing market conditions

b. Predictable and rigid processes

c. Emphasis on long-term planning

d. Traditional hierarchical organizational structure

4

|

5 Page 5 |

▲back to top |

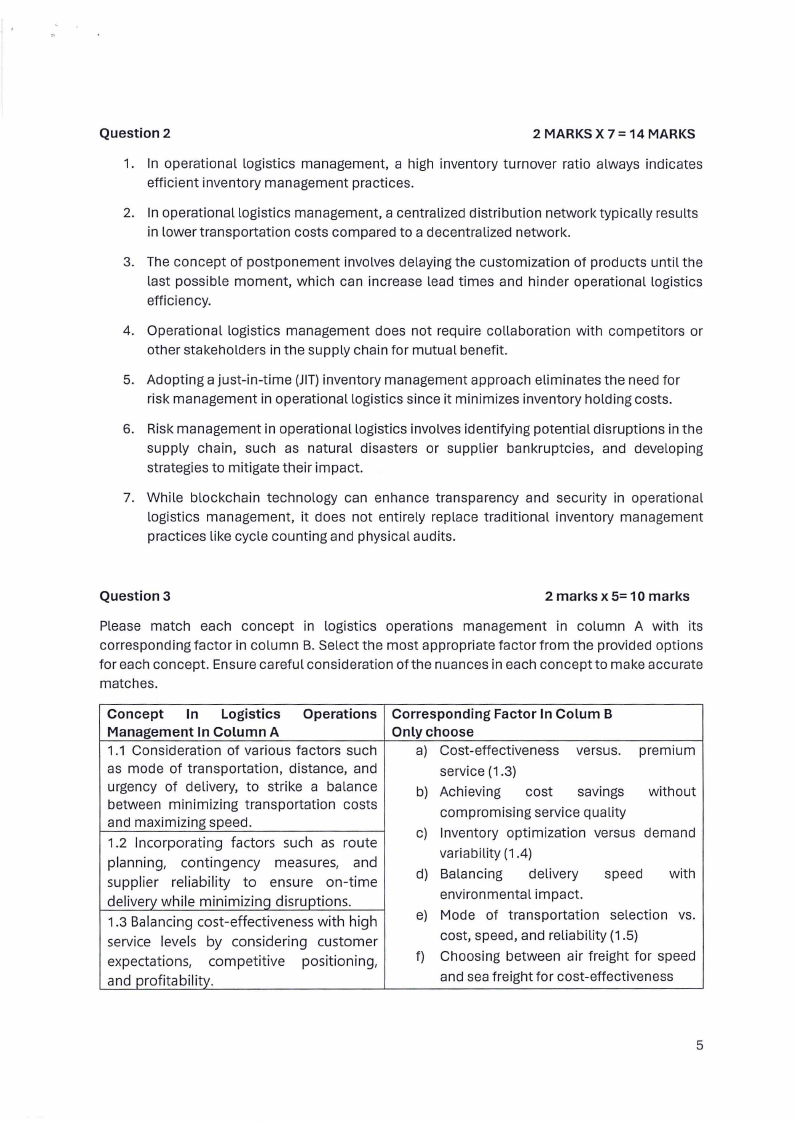

Question 2

2 MARKS X 7 = 14 MARKS

1. In operational logistics management, a high inventory turnover ratio always indicates

efficient inventory management practices.

2. In operational logistics management, a centralized distribution network typically results

in lower transportation costs compared to a decentralized network.

3. The concept of postponement involves delaying the customization of products until the

last possible moment, which can increase lead times and hinder operational logistics

efficiency.

4. Operational logistics management does not require collaboration with competitors or

other stakeholders in the supply chain for mutual benefit.

5. Adopting a just-in-time (JIT)inventory management approach eliminates the need for

risk management in operational logistics since it minimizes inventory holding costs.

6. Risk management in operational logistics involves identifying potential disruptions in the

supply chain, such as natural disasters or supplier bankruptcies, and developing

strategies to mitigate their impact.

7. While blockchain technology can enhance transparency and security in operational

logistics management, it does not entirely replace traditional inventory management

practices like cycle counting and physical audits.

Question 3

2 marks x 5= 1o marks

Please match each concept in logistics operations management in column A with its

corresponding factor in column B. Select the most appropriate factor from the provided options

for each concept. Ensure careful consideration of the nuances in each concept to make accurate

matches.

Concept In Logistics Operations

Management In Column A

1.1 Consideration of various factors such

as mode of transportation, distance, and

urgency of delivery, to strike a balance

between minimizing transportation costs

and maximizing speed.

1.2 Incorporating factors such as route

planning, contingency measures, and

supplier reliability to ensure on-time

delivery while minimizing disruptions.

1.3 Balancing cost-effectiveness with high

service levels by considering customer

expectations, competitive positioning,

and profitability.

Corresponding Factor In Colum B

Only choose

a) Cost-effectiveness versus. premium

service (1.3)

b) Achieving cost savings without

compromising service quality

c) Inventory optimization versus demand

variability {1.4)

d) Balancing delivery speed with

environmental impact.

e) Mode of transportation selection vs.

cost, speed, and reliability (1.5)

f) Choosing between air freight for speed

and sea freight for cost-effectiveness

5

|

6 Page 6 |

▲back to top |

1.4 Strategic alignment of inventory levels

with demand variability and supply chain

responsiveness, considering factors such

as demand forecasting accuracy, lead

times, and product lifecycles

1.5 Evaluating the trade-offs between

using different transportation modes, such

as road, rail, air, or sea, considering factors

like cost, speed, reliability, and

environmental impact.

g) Prioritizing cost efficiency over supplier

reliability

h) Cost optimization versus speed

prioritization (1.1)

i) Managing inventory turnover while

minimizing stockouts

j) On-time delivery versus disruption

mitigation (1.2)

SECTION A

CONSISTS OF TWO QUESTIONS

Question 4

Case Study: Leevi Manufacturing Company in the Automotive Parts Industry

Leevi Manufacturing Company has established itself as a leading player in the automotive parts

industry, renowned for its production of various components critical for vehicles. With a history

of delivering high-quality products, Leevi Manufacturing has garnered a strong reputation among

automotive manufacturers and consumers alike.

Despite its standing in the industry, Leevi Manufacturing faces significant operational challenges

that threaten its competitiveness and market position. These challenges revolve around

inefficient production processes, struggles with demand forecasting and inventory management,

and vulnerability to disruptions in the global supply chain.

Leevi Manufacturing's production processes, while functional, suffer from inefficiencies that

hinder its operational performance. Outdated machinery and equipment, coupled with

insufficient workforce training, contribute to frequent breakdowns and disruptions in production.

Additionally, the layout of production facilities may not be optimized for workflow efficiency,

leading to bottlenecks and delays. These inefficiencies result in increased lead times and

difficulties in meeting production schedules, ultimately affecting customer satisfaction and

market competitiveness.

Another area of concern for Leevi Manufacturing lies in its struggles with demand forecasting and

inventory management. Inaccurate demand forecasts, driven by volatile market conditions and

limited visibility into customer demand, lead to imbalances in inventory levels. Consequently, the

company faces challenges of either overstocking, tying up capital and storage space, or

understocking, resulting in stockouts and missed sales opportunities. Ineffective inventory

control practices exacerbate these challenges, further impacting the company's ability to

optimize production efficiency and meet customer demand effectively.

Leevi Manufacturing's operations are vulnerable to disruptions in the global supply chain, posing

significant risks to its supply chain continuity. Reliance on single-source suppliers, geopolitical

risks, natural disasters, and transportation disruptions can all impact the company's production

schedules and customer satisfaction. Any delay in deliveries, quality issues with raw materials,

6

|

7 Page 7 |

▲back to top |

or supply chain disturbances can have far-reaching consequences, affecting the company's

reputation and market competitiveness.

In light of these challenges, addressing inefficiencies in production processes, improving

demand forecasting and inventory management capabilities, and fortifying the supply chain

against disruptions are critical priorities for Leevi Manufacturing. By implementing strategic

initiatives to enhance operational efficiency and resilience, the company can navigate the

complexities of the automotive parts industry and sustain its competitive edge in the market.

Instructions to Students: After reading the case study of Leevi Manufacturing Company,

please prepare responses to the following discussion questions:

Question 5

Evaluate the impact of inefficient production processes on Leevi Manufacturing Company's

operations and its competitive position in the automotive parts industry. Discuss how these

inefficiencies contribute to bottlenecks, delays, and increased lead times, and analyze the

consequences for both production schedules and customer satisfaction. Additionally, assess

the potential risks and implications of failing to address these operational challenges effectively.

(18 marks)

Question 6

Critically analyze the factors contributing to Leevi Manufacturing Company's struggles with

demand forecasting and inventory management. Identify specific examples of inaccurate

forecasts and ineffective inventory control practices, and assess their implications for inventory

levels, capital utilization, and carrying costs. Discuss the importance of accurate demand

forecasting and effective inventory management in optimizing production efficiency and

enhancing customer satisfaction.

(18 marks)

Subtotal: 36 marks

Total:

100 marks

7