|

PDF711S - Phase Diagram and Formatting Processes 314 - 2nd Opp - June 2022 |

|

1 Page 1 |

▲back to top |

r

nAm I BI A un IVE RS ITV

OF SCIEnCE Ano TECHnOLOGY

FACULTYOF ENGINEERINGAND SPATIALSCIENCES

DEPARTMENT OF MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 08BMET

LEVEL: 7

COURSE CODE: PDF711S

COURSE NAME: PHASE DIAGRAMS AND FORMING

PROCESSES314

SESSION: JUNE 2022

DURATION: 2 HOURS

PAPER: THEORY

MARKS: 65

EXAMINER(S}

SECONDOPPORTUNITYQUESTIONPAPER

Mrs. Jaquiline Tatenda Kurasha

MODERATOR:

Professor Sofya Mitropolskaya

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examination paper.

2. Non-programmable calculator.

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

1

|

2 Page 2 |

▲back to top |

\\

|

3 Page 3 |

▲back to top |

Question 1 (15 Marks)

{a) What is the stacking sequence of the BCCcrystal structure. Explain you answer.

[2]

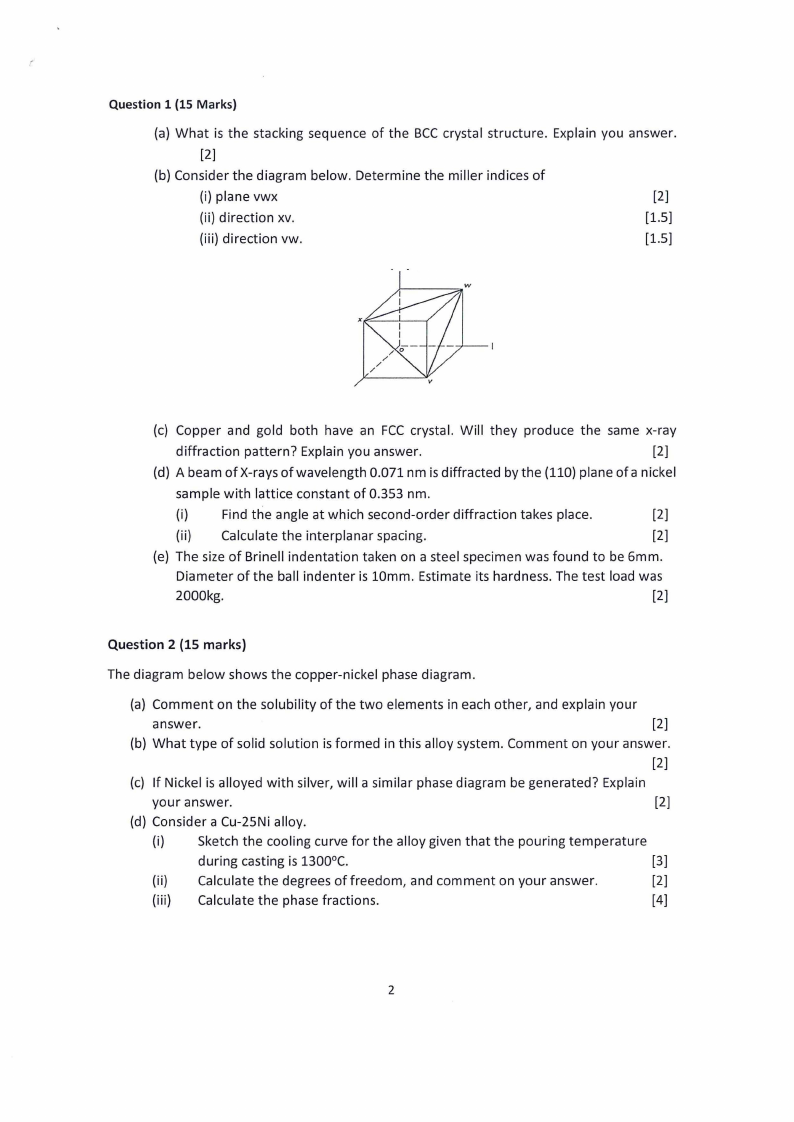

(b) Consider the diagram below. Determine the miller indices of

{i) plane vwx

[2]

{ii)direction xv.

(1.5]

(iii) direction vw.

[1.5]

{c) Copper and gold both have an FCC crystal. Will they produce the same x-ray

diffraction pattern? Explain you answer.

[2]

{d) A beam of X-rays of wavelength 0.071 nm is diffracted by the {110) plane of a nickel

sample with lattice constant of 0.353 nm.

{i)

Find the angle at which second-order diffraction takes place.

[2]

(ii) Calculate the interplanar spacing.

[2]

(e) The size of Brinell indentation taken on a steel specimen was found to be 6mm.

Diameter of the ball indenter is 10mm. Estimate its hardness. The test load was

2000kg.

[2]

Question 2 {15 marks)

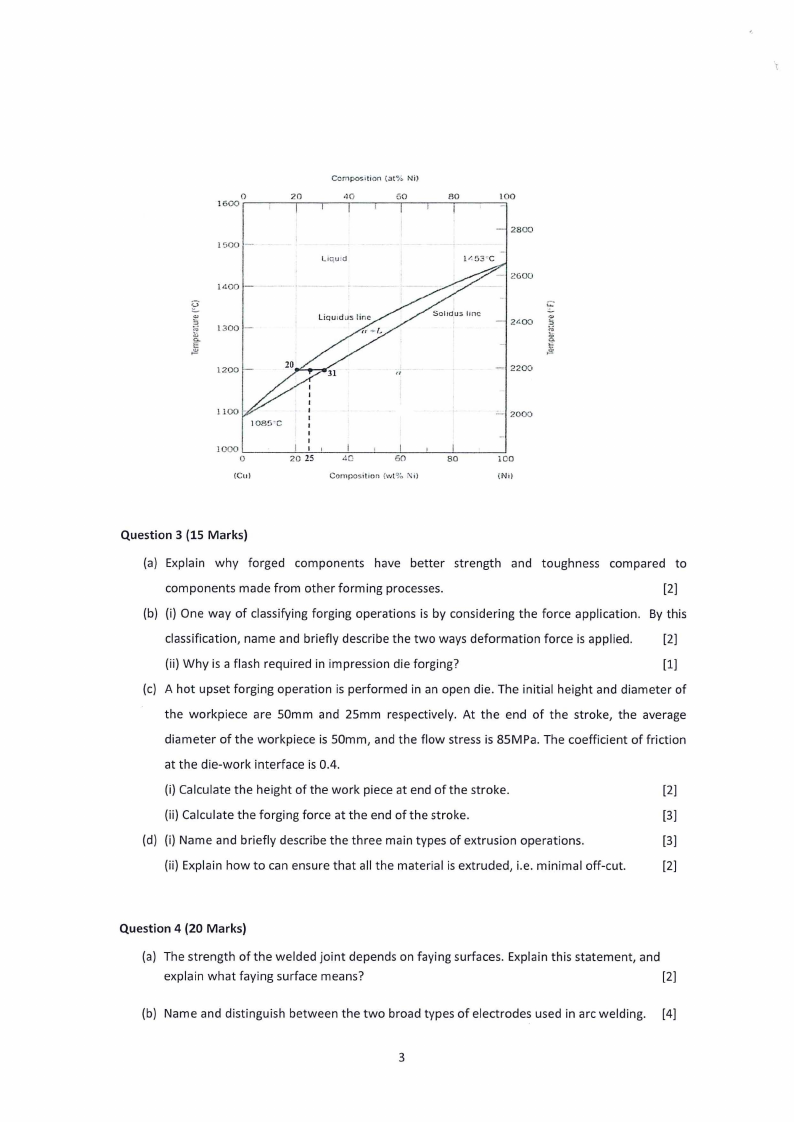

The diagram below shows the copper-nickel phase diagram.

(a) Comment on the solubility of the two elements in each other, and explain your

answer.

[2]

(b) What type of solid solution is formed in this alloy system. Comment on your answer.

[2]

(c) If Nickel is alloyed with silver, will a similar phase diagram be generated? Explain

your answer.

[2]

(d) Consider a Cu-25Ni alloy.

(i)

Sketch the cooling curve for the alloy given that the pouring temperature

during casting is 1300°C.

[3]

(ii) Calculate the degrees of freedom, and comment on your answer.

[2]

(iii) Calculate the phase fractions.

[4]

2

|

4 Page 4 |

▲back to top |

0

1600

Composition (at°/~ Ni)

20

,10

50

- 1500

1400 - --

E

""'' 1300 -

0.

E"'

1200 -

LIQU!d

-

.-

80

100

2800

i,.53--c

- 2600

....

2"-00

"""'''

",,'if!.

- 2200

1100

10B~:-c

I

I

1000

I

III

0

20 25

40

60

80

(Clll

Composition (wt~i:. N1)

.:__ 2000

100

(N1)

Question 3 (15 Marks)

(a) Explain why forged components have better strength and toughness compared to

components made from other forming processes.

[2)

(b) (i) One way of classifying forging operations is by considering the force application. By this

classification, name and briefly describe the two ways deformation force is applied.

[2)

(ii) Why is a flash required in impression die forging?

[1]

(c) A hot upset forging operation is performed in an open die. The initial height and diameter of

the workpiece are 50mm and 25mm respectively. At the end of the stroke, the average

diameter of the workpiece is 50mm, and the flow stress is 85MPa. The coefficient of friction

at the die-work interface is 0.4.

(i) Calculate the height of the work piece at end of the stroke.

[2)

(ii) Calculate the forging force at the end of the stroke.

[3)

(d) (i) Name and briefly describe the three main types of extrusion operations.

[3)

(ii) Explain how to can ensure that all the material is extruded, i.e. minimal off-cut.

[2)

Question 4 (20 Marks)

(a) The strength of the welded joint depends on faying surfaces. Explain this statement, and

explain what faying surface means?

[2)

(b) Name and distinguish between the two broad types of electrodes used in arc welding. [4]

3

|

5 Page 5 |

▲back to top |

(c) Distortion/warping is a serious problem in fusion welding. Suggest three ways to minimize

distortion.

[3]

(d) With the aid of a diagram, explain what heat affected zone (HAZ) means in fusion welding,

and describe the microstructure observed in the HAZ.

[3]

(e) Mechanical joining is generally classified as non-permanent joining.

(i)

Give one exception to this classification and suggest three circumstances under

which the exception is used.

(4]

(ii)

Give two advantages and two disadvantages of mechanical joining.

(4]

End of Question Paper.

4

|

6 Page 6 |

▲back to top |