|

PNM710S - Pyrometallurgy on Non-Ferrous Metals- 1st OPP - JUN 2023 |

|

1 Page 1 |

▲back to top |

n Am I BI A u n IVE Rs ITY

OF SCIEnCE Ano TECHnOLOGY

FACULTY OF ENGINEERING AND SPATIAL SCIENCES

DEPARTMENT OF MECHANICAL, MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 08BMET

LEVEL: 8

COURSE CODE: PNM710S

COURSE NAME: PYROMETALLURGY OF NON-

FERROUS METALS

SESSION: JUNE 2023

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

FIRST OPPORTUNITY EXAM PAPER

Prof. Godfrey Dzinomwa

MODERATOR:

Prof. Sofya Mitropolskaya

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each questions are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 5 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

Question 1

(a) Discuss the advantages of using a Top Submerged Lance (TSL) furnace compared to an

electric furnace in the smelting of copper sulphide concentrates (5 marks).

(b) By applying Stoke's law, derive an expression for the settling velocity Vs of a matte droplet

of density Ps in a molten slag of density Pt in terms of the diameter d and density of the

matte droplet, and the viscosityµ and density of the slag from first principles. Assume that

the rate of settling obeys Stoke's law, and that the frictional force between matte droplets

and slag= 6Vµm (5 marks).

(c) Given that matte density is 5500kg/m 3, slag density is 3500kg/m 3 and slag viscosity is 0.1

kg/m.s, calculate the settling velocities of and the times taken by matte droplets of radii in

mm; 12; 10; 8; 4; 2 settling through 2m of slag? (10 marks).

p(matte) = 5500 kg/m 3

p(slag) = 3500 kg/m 3

µ(slag)= 0.1 kg/m 3

Settling in 2m of slag.

(d) How do matte droplets get entrained in slag during converting and what practical measures

are applied in industry in order to increase the rate at which matte droplets settle out of the

slag (5 marks).

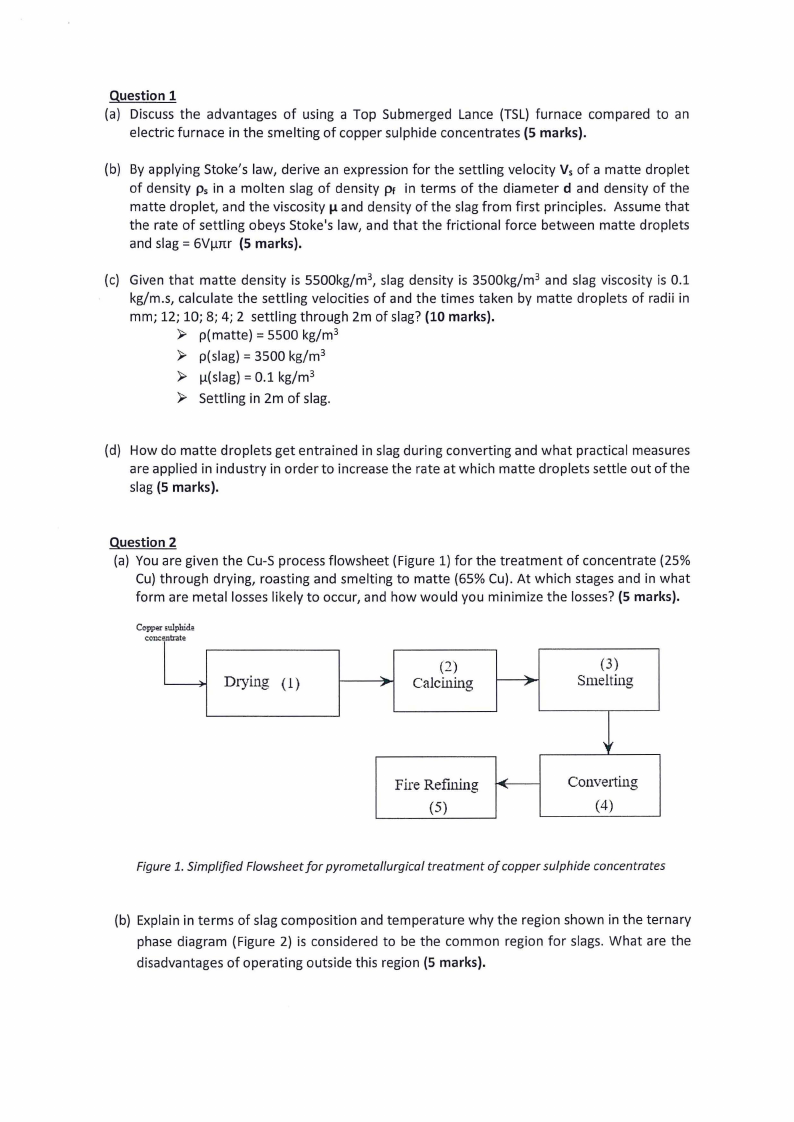

Question 2

(a) You are given the Cu-S process flowsheet (Figure 1) for the treatment of concentrate {25%

Cu) through drying, roasting and smelting to matte {65% Cu). At which stages and in what

form are metal losses likely to occur, and how would you minimize the losses? (5 marks).

Copper ,ulplrida

con:: ntrate

Drying (1)

(2)

(3)

.,. Calcining

r

Smelting

Fire Refining .i...

(5)

"

Converting

(4)

Figure 1. Simplified Flowsheet for pyrometallurgical treatment of copper sulphide concentrates

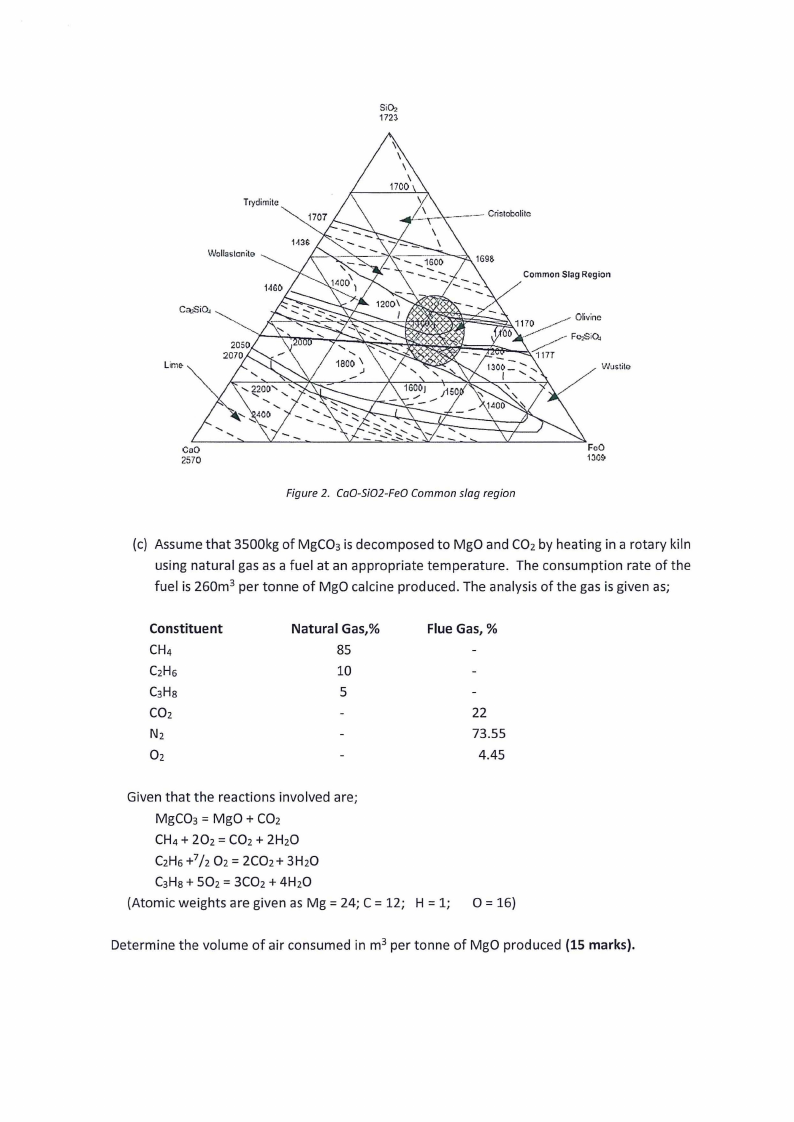

(b) Explain in terms of slag composition and temperature why the region shown in the ternary

phase diagram (Figure 2) is considered to be the common region for slags. What are the

disadvantages of operating outside this region (5 marks).

|

3 Page 3 |

▲back to top |

SiO,

172~

Trydimite

Ca.,SiOJ

2050'

2070

Lim~

Common Slag Region

11 70

_.,,,...O.-livine

_,,,--

00 ...--- _,..- F<...,SOi J

coo

FcO

2570

13C~

Figure 2. Ca0-Si02-Fe0 Common slag region

(c) Assume that 3500kg of MgCO3is decomposed to MgO and CO2by heating in a rotary kiln

using natural gas as a fuel at an appropriate temperature. The consumption rate of the

fuel is 260m 3 per tonne of MgO calcine produced. The analysis of the gas is given as;

Constituent

CH4

C2H5

C3Hs

CO2

N2

02

Natural Gas,%

85

10

5

Flue Gas,%

22

73.55

4.45

Given that the reactions involved are;

MgCO3 = MgO + CO2

CH4+ 202 = CO2+ 2H2O

C2H5+7h 02 = 2CO2+ 3H2O

C3Hs+ 502 = 3CO2+ 4H2O

(Atomic weights are given as Mg= 24; C = 12; H = 1;

0 = 16)

Determine the volume of air consumed in m3 per tonne of MgO produced (15 marks).

|

4 Page 4 |

▲back to top |

Question 3

(a) Explain the reason why the blast furnace has generally been replaced by other types of

furnaces such as reverberatory and electric furnaces in the smelting of lead rich ores (5

marks).

(b) A furnace is charged with 3 000 kg/min of copper concentrate which is composed of the

following constituents;

Chalcopyrite (CuFeS2):

65%

Pyrite (FeS2):

20%

Silica (Silica):

15%

The Copper Matte produced contains

and the Slag contains

60% Cu;

15% Fe;

25%S

35% Fe

Assume that the reactions involved are;

2CuFeS2

=

Cu2S+ 2FeS + ½S2

FeS2

=

FeS+ ½S2

½S2 + 02 =

FeS+ 3h02

=

SO2

FeO + SO2

FeO + SiO2 =

FeO.SiO2

Determine the amount of;

(i) air blown into the furnace (5 marks),

(ii) matte formed (5 marks),

(iii) slag formed (5 marks), and

(iv) SO2in flue gases leaving the furnace (5 marks)

(Note: Relevant Atomic weights are Cu= 64; Fe= 56; 5 =32; Si= 28; O =16}

Question 4

(a) Discuss the factors that you would consider in order to set up a green hydrogen

manufacturing plant in a given location, and whether you consider Namibia to be a

favourable destination for such an investment. What are the global benefits of utilising green

hydrogen energy as compared to fossil fuels (5 marks).

(b) What factors would you consider to be critical before you set up an Aluminium smelter in any

country? (5 marks)

(c) Copper ore concentrate with the following assay

26.5% Cu

20%S

10% H2O

is processed to produce copper metal assaying 98.5% Cu. The off-gases are treated to

recover Sulphur in the form of Sulphuric acid. Assuming 300 tph of ore concentrate;

|

5 Page 5 |

▲back to top |

{i) Determine the amount of H2S04 {dry) produced in tph if 85% of the S in the feed is

recovered in the H2S04acid plant (10 marks)

(ii)The process flowsheet shows that Cu is upgraded at three main stages, and 2% of the Cu

is lost at each of the stages. How much of the final product is produced in tph? (5 marks)

(Note: Atomic weights are Cu= 64, S =32, O =16, H =1}

---------------

END -------------