|

GSC711S- GLOBAL LOGISTICS AND SUPPLY CHAIN MANAGEMENT- 2ND OPP- JULY 2024 |

|

1 Page 1 |

▲back to top |

nAmI BI AunIVE RSITY

OF SCIEnCE Ano TECHnOLOGY

FACULTY OF COMMERCE, HUMAN SCIENCES, AND EDUCATION

DEPARTMENT OF MARKETING, LOGISTICS AND SPORT MANAGEMENT

QUALIFICATION: BACHELOR OF LOGISTICSAND SUPPLY CHAIN MANAGEMENT

BACHELOR OF PROCUREMENT AND SUPPLY CHAIN MANAGEMENT

QUALIFICATION CODE: 07 BLSC

07 BPSM

LEVEL: 7

COURSE CODE: GSC711S

COURSE NAME: GLOBAL LOGISTICS AND SUPPLY

CHAIN MANAGEMENT

SESSION: JULY 2024

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

MODERATOR:

SECOND OPPORTUNITY EXAMINATION QUESTION PAPER

MS. E JESAYA (FM & DI)

MR. P SHIFETA (EF)

MS. D KALOIA (PM)

MS. TA SHIKESHO

INSTRUCTIONS

1. Answer ALL the questions.

2. Read all the questions carefully before answering.

3. Number the answers clearly.

THIS QUESTION PAPER CONSISTS OF 6 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

SECTION A: MULTIPLE CHOICE AND TRUE/FALSE QUESTIONS

50 MARKS

QUESTION 1: MULTIPLE CHOICE

40 MARKS

There are 20 Multiple-choice questions with several possible choices each. Choose the best

possible answer, for example, lA. Each question is equivalent to 2 marks.

1. Which one of the following is NOT a type of layout in manufacturing?

[2 marks]

a) Fixed position layout

b) Cell-based layout

c) Product flow layout

d) All the above answers are collect

2. The following 6 C's need to be considered when choosing channels of distribution:

[2 marks]

a) Cost, communication, control, coverage, character, continuity

b) Cost, consolidation, control, coverage, character, continuity

c) Cost, capital requirement, control, coverage, character, continuity

d) Cost, configuration, control, coverage, character, continuity

3. The following are trends shaping logistics and supply chain operations:

[2 Marks]

a) Cost pressure

b) Volatility

c) Networked economy

d) All of the above

e) Only A and Care correct

4. International distribution strategies include the following:

[2 Marks]

a) Internal department

b) Working with distributors

c) Online

d) All of the above

e) Only Band Care correct

5. The following factors contribute to the increased complexity and cost of global logistics:

[2 Marks]

a) Distance

b) Regulation

c) Interchange rate fluctuations

d) All of the above

e) Only A and Bare correct

6. ____ is a process that facilitates a business that sells products or services, or both, to

consumers for their personal or family use.

[2 Marks]

a) Global logistics

b) Global supply chain

c) Retailing

d} International trade

7. Wal Mart is an example of ___ _

[2 Marks]

2

|

3 Page 3 |

▲back to top |

a) Specialized retailer

b) Large retailer

c) Mixed retailer

d) Customised retailer

8. _____

is a strategy that companies utilise to get control over their suppliers or

distributors in order to attain a bigger market share reduce transaction costs, and secure

supplies.

[2marks]

a) Horizontal integration

b) Supply chain integration

c) Vertical integration

d) Procurement integration

9. ______

is an ongoing relationship between firms, which involves a commitment

over an extended time period, and a mutual sharing of information and the risks and

rewards of the relationship.

[2 marks]

a) Supplier partnering

b) Supply Chain Management

c) Customer Management

d) Supplier Management

10. Which one of the followings is NOT the measure of integration?

[2 marks]

a) Delivery frequencies

b) Access to planning system

c) Knowledge of inventory levels

d) All the above answers are collect

11. is the glue that holds the supply chain together and plays an important role in

integrating the various role players in the chain.

[2 marks]

a) Integration

b) Collaboration

c) All of the above

d) None of the above

12. Which one of the followings is NOT the main feature of strategic alliances? [2 marks]

a) Openness and mutual trust

b) Short-term commitment

c) Increasing business between partners

d) Guaranteed reliable and high quality goods and services

13. _____

shapes the nature of the supply chain and ultimately consists of those

decisions that influence the investment patterns made by the firm across its various supply

chains.

[2 marks]

a) Supply chain collaboration

b) Supply chain design

c) Supply chain integration

d) Supply chain management

3

|

4 Page 4 |

▲back to top |

14. Which one of the following is NOT part of redesigning an existing factory?

[2 marks]

a) Strategic decision

b) Sales team inputs

c) Location planning considerations

d) Aggregated level information

15. _____

can be used from a DCif the lot sizes to be delivered to each buyer location

are small.

[2 marks]

a) Tailored network

b) Shipping via DC using milk runs

c) All shipments via intermediate transit points with cross-docking

d) Direct shipping

16. ______

selects the preferred factory layout variant based on factors such as

efficiency, feasibility, and alignment with strategic objectives.

[2 marks]

a) Media planning

b) Creation of detailed plans

c) Detailed planning process

d) Decision on preferred layout management

17. Which one of the following is NOT a basic layout requirement?

[2 marks]

a) Identification of movement costs between jobs

b) Decisions related to the environment and aesthetic

c) Understanding the needs of capacity and space

d) All the above answers are correct

18. _____

is a digital technology that enables the implementation of intelligent

factories or adjustable production and logistics networks and provides further

possibilities for companies such as smart maintenance or smart logistics. [2 marks]

a) Internet of Things (loT)

b) Blockchain

c) Artificial Intelligence (Al)

d) Robotics and Automation

19. _____

is a tool for representing, analyzing and configuring supply chains.

a) Michael Porter's Value Chain Analysis

b) SCORModel

c) Michael Porter's Five Forces

d) SWOT Analysis

20. _____

are integrations of computation with physical processes.

a) Artificial Intelligence (Al)

b) Cyber Physical Systems (CPS)

c) Internet of Things (loT)

d) Blockchain

[2 marks]

[2 marks]

SUB-TOTALMARKS:40

4

|

5 Page 5 |

▲back to top |

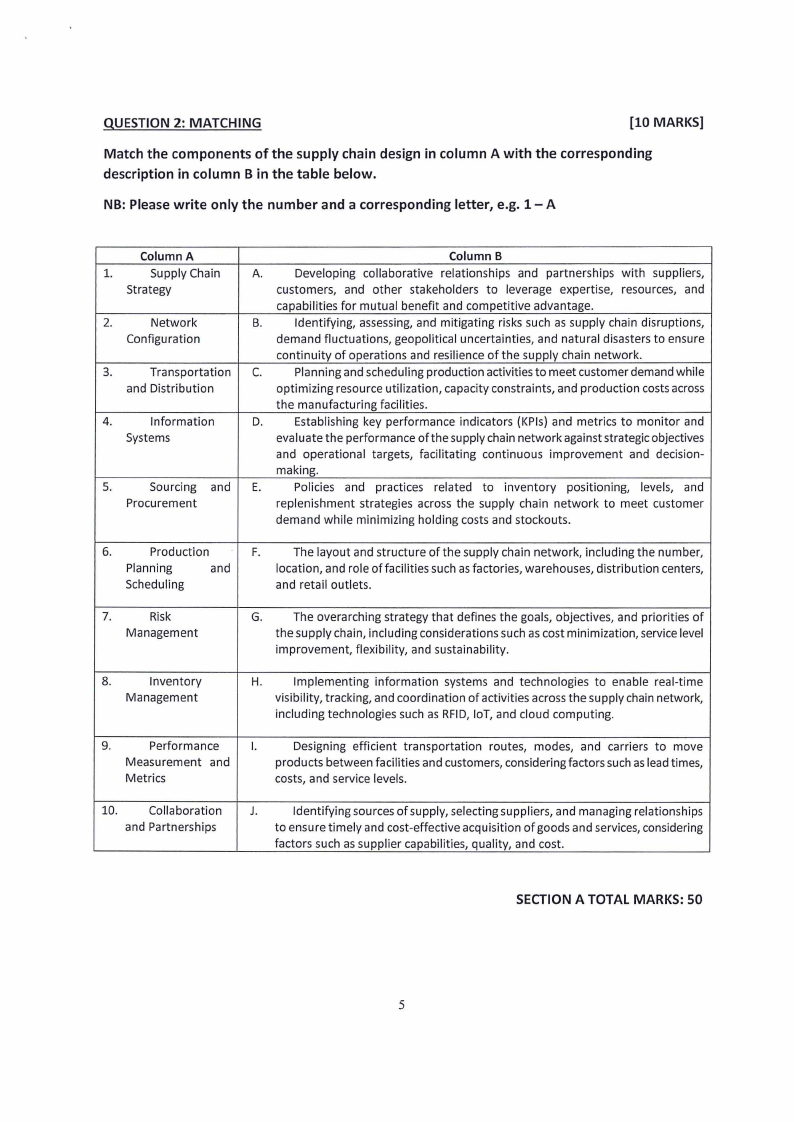

QUESTION 2: MATCHING

[10 MARKS]

Match the components of the supply chain design in column A with the corresponding

description in column Bin the table below.

NB: Please write only the number and a corresponding letter, e.g. 1- A

Column A

1.

Supply Chain

Strategy

2.

Network

Configuration

3.

Transportation

and Distribution

4.

Information

Systems

5.

Sourcing and

Procurement

Column B

A. Developing collaborative relationships and partnerships with suppliers,

customers, and other stakeholders to leverage expertise, resources, and

capabilities for mutual benefit and competitive advantage.

B.

Identifying, assessing, and mitigating risks such as supply chain disruptions,

demand fluctuations, geopolitical uncertainties, and natural disasters to ensure

continuity of operations and resilience of the supply chain network.

C.

Planning and scheduling production activities to meet customer demand while

optimizing resource utilization, capacity constraints, and production costs across

the manufacturing facilities.

D.

Establishing key performance indicators (KPls) and metrics to monitor and

evaluate the performance of the supply chain network against strategic objectives

and operational targets, facilitating continuous improvement and decision-

making.

E.

Policies and practices related to inventory positioning, levels, and

replenishment strategies across the supply chain network to meet customer

demand while minimizing holding costs and stockouts.

6.

Production

Planning

and

Scheduling

F.

The layout and structure of the supply chain network, including the number,

location, and role of facilities such as factories, warehouses, distribution centers,

and retail outlets.

7.

Risk

Management

G. The overarching strategy that defines the goals, objectives, and priorities of

the supply chain, including considerations such as cost minimization, service level

improvement, flexibility, and sustainability.

8.

Inventory

Management

H. Implementing information systems and technologies to enable real-time

visibility, tracking, and coordination of activities across the supply chain network,

including technologies such as RFID,loT, and cloud computing.

9.

Performance

Measurement and

Metrics

I.

Designing efficient transportation routes, modes, and carriers to move

products between facilities and customers, considering factors such as lead times,

costs, and service levels.

10.

Collaboration

and Partnerships

J.

Identifying sources of supply, selecting suppliers, and managing relationships

to ensure timely and cost-effective acquisition of goods and services, considering

factors such as supplier capabilities, quality, and cost.

SECTION A TOTAL MARKS: 50

5

|

6 Page 6 |

▲back to top |

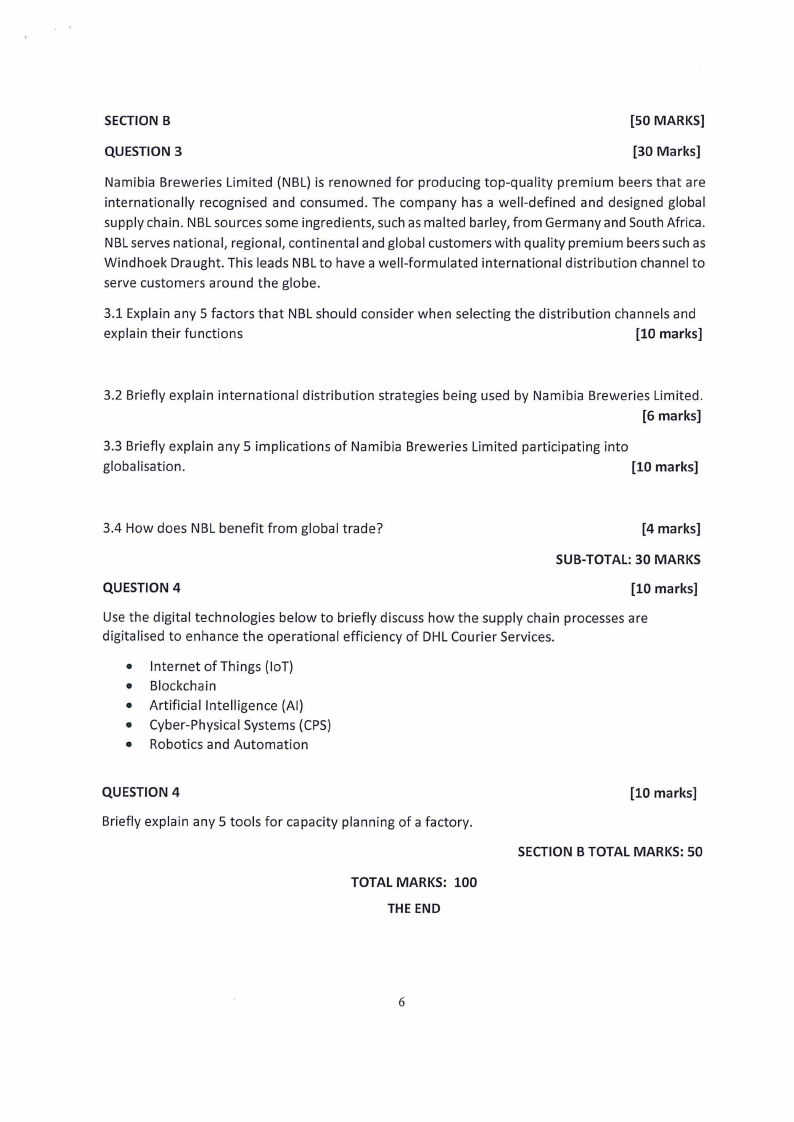

SECTION B

[50 MARKS]

QUESTION 3

[30 Marks]

Namibia Breweries Limited (NBL) is renowned for producing top-quality premium beers that are

internationally recognised and consumed. The company has a well-defined and designed global

supply chain. NBL sources some ingredients, such as malted barley, from Germany and South Africa.

NBLserves national, regional, continental and global customers with quality premium beers such as

Windhoek Draught. This leads NBLto have a well-formulated international distribution channel to

serve customers around the globe.

3.1 Explain any 5 factors that NBL should consider when selecting the distribution channels and

explain their functions

[10 marks]

3.2 Briefly explain international distribution strategies being used by Namibia Breweries Limited.

[6 marks]

3.3 Briefly explain any 5 implications of Namibia Breweries Limited participating into

globalisation.

[10 marks]

3.4 How does NBL benefit from global trade?

[4 marks]

SUB-TOTAL: 30 MARKS

QUESTION 4

[10 marks]

Use the digital technologies below to briefly discuss how the supply chain processes are

digitalised to enhance the operational efficiency of DHL Courier Services.

• Internet of Things (loT)

• Blockchain

• Artificial Intelligence (Al)

• Cyber-Physical Systems (CPS)

• Robotics and Automation

QUESTION 4

Briefly explain any 5 tools for capacity planning of a factory.

TOTAL MARKS: 100

THE END

[10 marks]

SECTION B TOTAL MARKS: 50

6