|

MPT721S - Mineral Processing Techniques and Applications 324 - 2nd Opp - Nov 2022 |

|

1 Page 1 |

▲back to top |

nAm I BIA un IVERSITY

OFSCIEnCEAno TECHnOLOGY

FACULTY OF ENGINEERING

DEPARTMENT OF MINING AND PROCESS ENGINEERING

QUALIFICATION : BACHELOR OF ENGINEERING IN METALLURGY, CHEMICAL

ENGINEERING & MINING ENGINEERING

QUALIFICATION CODE: BSc.

COURSE CODE: MPT721S

LEVEL: 7

COURSE NAME: MINERAL PROCESSING

TECHNIQUES AND APPLICATIONS 324

SESSION: OCTOBER 2022

DURATION: 3 HOURS

PAPER: THEORY

MARKS:100

SECOND OPPORTUNITY QUESTION PAPER

EXAMINER(S)

Dr. Clement K. Owusu

Mr. Thomas Moongo

MODERATOR:

Prof. Godfrey Dzinomwa

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and prese_n~ple._-:--.~- , .

PERMISSIBLE MATERIALS

-- .- -

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 3 PAGES (Including this front page)

1

|

2 Page 2 |

▲back to top |

Question 1

a. During a routine check at the plant, it was observed that the oxygen and

cyanide concentration were far below the set point. The oxygenation and

cyanide supply system when checked was functioning very well. A check from

the mineralogical data supplied by the geologist revealed the presence of iron

and copper sulphide minerals. As a metallurgist on site discuss the possible

cause for observed drop in oxygen and cyanide concentration. What will the

effect when the problem is not rectified?

(10 marks)

b. Mention five (5) operating variables that regulate the flotation minerals

(10marks)

c. Tin ore assaying 10% Sn is fed to a concentration plant at the rate of 100

tons/hr. If the grades of concentrate and tailing are 40% Sn and 1 % Sn, calculate

the recovery of tin and tin lost in tailing in tons/hr.

(15 marks)

Question2

a. Develop a simple beneficiation flow chart for uraninite

(15 marks)

b. Explain the following terms as applied in froth flotation

i. Entrainment

(2 marks)

ii. Induction time

(2 marks)

iii. Contact time

(2 marks)

tea c. 100 g of graphite with 60% carbon is to aflotation ceJiJn llie-labor~t~y. -By-- --·

using proper reagents 50 g of concentrate assaying 90% carbon -is obtained.

Calculate the percentage recovery, ratio of concentration and ratio of enrichment,

(10 marks)

- •.:.-.:.;-:::.::.~:-.:._.-._-:-:_:-:_:-:.-- -----~-..-:-.=--=--=---:-,:--=-·..-:._ .... ·- - -- - --- --,:_--- -·..•·- -- - --·- -· ·- --· ----·~~~---- - ··--=-=-~·---~-·---·-

- ----·---·----_--_-·

----------

- - --

2

-- ~--- --· - -·

-- -

~- .-.-.:._. _ -.:.. -:-. ~ .-...

.·.:. -::· :...-- ~--;-_:·-.

- .. --

-----

-

-.

|

3 Page 3 |

▲back to top |

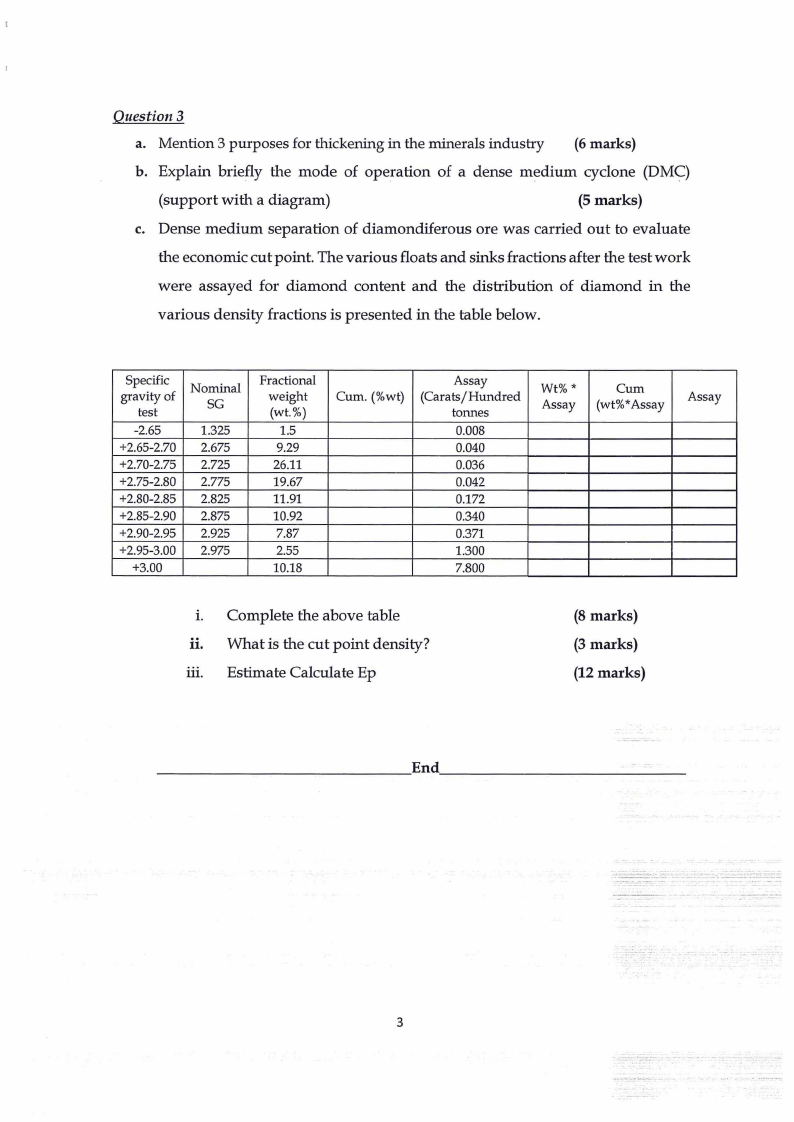

Question 3

a. Mention 3 purposes for thickening in the minerals industry (6 marks)

b. Explain briefly the mode of operation of a dense medium cyclone (DMC)

(support with a diagram)

(5 marks)

c. Dense medium separation of diamondiferous ore was carried out to evaluate

the economic cut point. The various floats and sinks fractions after the test work

were assayed for diamond content and the distribution of diamond in the

various density fractions is presented in the table below.

Specific

gravity of

test

-2.65

+2.65-2.70

+2.70-2.75

+2.75-2.80

+2.80-2.85

+2.85-2.90

+2.90-2.95

+2.95-3.00

+3.00

Nominal

SG

1.325

2.675

2.725

2.775

2.825

2.875

2.925

2.975

Fractional

weight

(wt.%)

1.5

9.29

26.11

19.67

11.91

10.92

7.87

2.55

10.18

Cum. (%wt)

Assay

(Carats/Hundred

tonnes

0.008

0.040

0.036

0.042

0.172

0.340

0.371

1.300

7.800

Wt%*

Assay

Cum

(wt%*Assay

Assay

i. Complete the above table

ii. What is the cut point density?

iii. Estimate Calculate Ep

(8 marks)

(3 marks)

(12 marks)

_______________

End_____________

_

3

|

4 Page 4 |

▲back to top |