|

SQC802S - STATISTICAL QUALITY CONTROL - 1ST OPP - NOV 2022 |

|

1 Page 1 |

▲back to top |

nAml BIA UnlVERSITY

OF SCIEnCE Ano TECHnOLOGY

FACULTY OF HEALTH AND APPLIED SCIENCES

DEPARTMENT OF MATHEMATICS

I QUALIFICATION:

PROGRAMME

I CODE:

I COURSE CODE:

I SESSION:

I DURATION:

BACHELOR OF SCIENCE HONOURS IN APPLIED MATHEMAT-

ICS AND STATISTICS

08BSHS

I LEVEL: 8

SQC802S

NOV 2022

3 HOURS

COURSE

I NAME:

I PAPER:

I MARKS

I STATISTICAL QUALITY CONTROL

THEORY

100

FIRST

I EXAMINER

I MODERATOR

OPPORTUNITY

EXAMINATION QUESTION PAPER

I Dr. Jacob Ong'ala

I Prof Sathiya Appunni

INSTRUCTION

1. Answer all the questions

2. Show clearly all the steps in the calculations

3. All written work must be done in blue and black ink

THIS QUESTION

PERMISSIBLE MATERIALS

Non-programmable calculator without cover

PAPER CONSISTS OF 7 PAGES (including the front page and

attachments)

1

|

2 Page 2 |

▲back to top |

QUESTION ONE - 25 MARKS

(a) Suppose that we have a product (produced under 3-sigma) consisting of an assembly of 100

independent components or parts and all 100 of these parts must be non-defective for the

product to function satisfactorily. What is the probability that any specific unit of product

is non-defective

[3 mks]

(b) Why would a typical automobile company manufacturing particular vehicles with about

100,000 components each use six-sigma instead of five-sigma for assessing their quality per-

formance?

[5 mks]

(c) Consider the Shewhart .'i control chart with two-sigma limits

(i) Find the probability that a single point falls outside the limits when the process is in

control

[2 mks]

(ii) what sample number will produce an out-of control signal

[2 mks]

(iii) Calculate the standard deviation of the average run length

[2 mks]

(d) A manufacturer of components for automobile transmissions wants to use control charts

to monitor a process producing a shaft. The resulting data from 20 samples of 4 shaft

diameters that have been measured are:

LXi 20

= 10.275

i=l

and

LR;= 20

1.012

i=l

(i) Find the control limits that should be used on the x and R control charts.

[6 mks]

(ii) Find the probability of detecting a shift of 0.8cr in thefirst sample if the process is

monitored under 3 sigma.

[3 mks]

(iii) What is the expected number of samples that must betaken before the shift is detected

[2 mks]

QUESTION TWO - 18 MARKS

(a) Select one specific product and one service of your choice, and discuss how the eight dimen-

sions of quality impact its overall acceptance by consumers

[8 mks]

2

|

3 Page 3 |

▲back to top |

(b) Quality and process improvement occurs most effectively on a project-by-project basis.

DMAIC is a structured five-step problem-solving procedure that can be used to success-

fully complete projects by proceeding through and implementing solutions that are designed

to solve root causes of quality and process problems, and to establish best practices to en-

sure that the solutions are permanent and can be replicated in other relevant business

operations. Explain the five steps in DMAIC process (stating clearly the goalandactivities

in each step)

[10 mks]

QUESTION THREE - 24 MARKS

A high-voltage power supply should have a nominal output voltage of 350 V. A sample of

four units is selected each day and tested for process-control purposes. The data shown in

Table 1 give the difference between the observed reading on each unit and the nominal voltage

times ten; that is, Xi = (observed voltage on unit i - 350)10.

Table 1: Voltage Data for Question 3.

Sample No. XI x2 X3 X4

1 6 9 10 15

2 10 4 6 11

3 7 8 10 5

4 8 9 6 13

5 9 10 7 13

6 12 11 10 10

7 16 10 8 9

8 7 5 10 4

9 9 7 8 12

10 15 16 10 13

11 8 12 14 16

12 6 13 9 11

13 16 9 13 15

14 7 13 10 12

15 11 7 10 16

16 15 10 11 14

17 9 8 12 10

18 15 7 10 11

19 8 6 9 12

20 13 14 11 15

(a) Set up x and R charts on this process. Is the process in statistical control?.

[4 mks]

(b) If specifications are at 350V ± 0.5V, what can you say about process capability?

[4 mks]

QUESTION FOUR - 21 MARKS

Frozen orange juice concentrate is packed in 6-oz cardboard cans. These cans are formed

on a machine by spinning them from cardboard stock and attaching a metal bottom panel. By

3

|

4 Page 4 |

▲back to top |

inspection of a can, we may determine whether, when filled, it could possibly leak either on

the side seam or around the bottom joint. Such a nonconforming can has an improper seal on

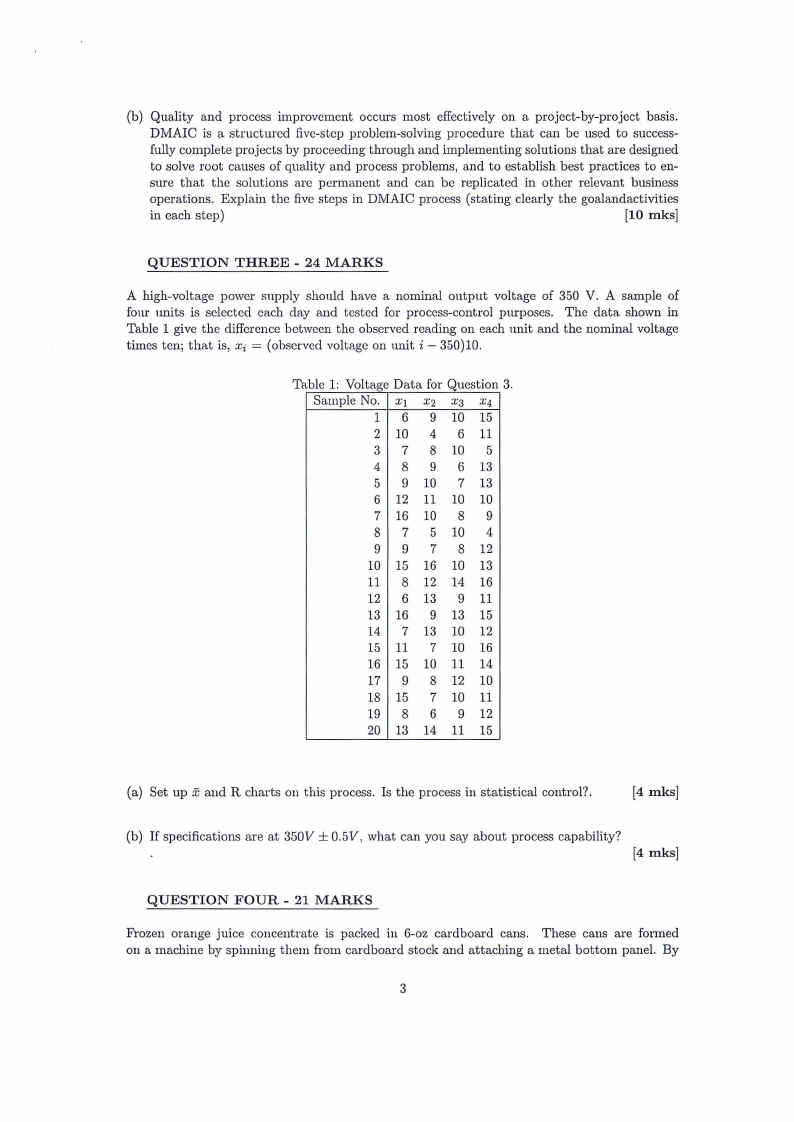

either the side seam or the bottom panel. The data is shown in the table below

= Sample Size n 50

Sample

Number

.Number or

Nonconforming

Cnns,D;

I

12

2

15

3

8

4

10

5

4

6

7

7

16

8

9

9

14

10

10

II

5

12

6

13

17

14

12

15

22

16

8

Sample

Number

17

18

19

20

21

22

23

24

25

26

27

28

29

30

-

Number of

Nonconforming

Cans, D;

JO

5

13

II

20

18

24

15

9

12

7

13

9

6

S:1mple

Number

31

32

33

34

35

36

37

38

39

40

41

42

43

Number or

Nonconforming

Cans,D,

9

6

12

5

6

4

6

3

7

6

2

4

3

Sample

Number

44

45

46

47

48

49

50

51

52

53

54

Number of

Nonconforming

Cons,D 1

6

5

4

8

5

6

7

5

6

3

5

Figure 1: Number of Defective products from each sample of 50

(a) Set up a control chart to improve the fraction of nonconforming cans produced by this

machine using the first 30 samples

[10 mks]

(b) Assuming the out of control points (15 and 23) are due to new batch of raw materials put

into production and a relatively inexperienced operator had been temporarily assigned to

the machine respectively, Correct the limits of the control charts with this information.

[3 mks]

(c) Using the new set of data, plot the a fraction nonconforming chart using the adjusted limit.

[3 mks]

(d) based on the graph in (c) above perform a statistical test if the process has shifted?

[5 mks]

QUESTION FIVE - 12 MARKS

(a) State 3 advantages and 2 disadvantages of acceptance sampling

(b) Describe the following sampling plans

(i) single-sampling plan

(ii) Double-sampling plan

(iii) Multiple-sampling plan

[6 mks]

[2 mks]

[2 mks]

[2 mks]

- END OF QUESTIONS -

4

|

5 Page 5 |

▲back to top |

---------- ---·-----·· ------·--·-···---------

:.c:c

-

Chari fur An~mJ!c.."i

Chart rurStandard DcYiations

Obsen·otions

In

S.Umple,n

Fudors fur

Control UmiLc;;

A

,1,

AJ

Fnctors for

Cl•nll'r Linl'

c,

11c,

factors fur Control l..imits

n, H, n, n.

2

:!.121 I.HSU 2.659 0.7979 1.2533 ()

3

um 1.732

1.954 0.8862 1.1284 ()

3.267 0

2.568 I)

2.606

::!.276

4

1.500 0.7.29 1.6:!S 0.921J 1.0~54 (I

2.166 0

2.088

5

1.342 0.577 1.427 0.9400 1.0638 ()

2.089 0

1.964

6

1.225 U.483 1.287 0.9515 1.0510 0.030 1.970 O.o2'J 1.874

7

1.134 0.419 1.182 IJ.95')4 1.(1-123 0.118 1.882 IJ.113 1.8116

8

1.061 0.373 1.099 0.%50 1.0363 0.185 1.815 0.17') 1.751

9

1.(1()0 0.337 1.()32 0.9693 1.0317 0.239 1.761 0.23:! 1.707

IO 0.949 0.308 0.975 0.9727 1.0281 0.284 1.716 0.276 1.669

II

0.905 0.285 0.927 0.9754 1.0152 0.321 1.679 0.313 1.637

12

0.866 0.26<1 0.886 0.9776 1.0229 0.354 1.646 IJ.346 J.611)

13 0.S32 0.249 0.850 0.9794 J.02JO 0.382 1.618 0.374 1.585

14 0.802 0..:!35 0.817 0.9SJ(J 1.0194 0.406 1.594 0.3'J<J 1.563

15 0.775 0.~3 0.789 0.982.1 1.0180 0.428 1.572 0.421 1.544

16 0.750 0.21:! 0.76.l 0.9835 1.0168 0.448 1.55:! 0.440 1.526

17 0.728 0.203 0.739 0.9845 1.0157 ll.466 1.534 0.458 1.51 I

18 0.707 0.194 0.718 0.9854 1.0148 U.482 1.518 0.475 1.4%

19 0.688 0.187 0.698 0.9862 1.0140 0.497 1.503 0.490 1.483

20

0.671 0.180 0.(,80 0.9S69 1.01:13 0.510 1.4')0 0.511-1 1.470

21

0.655 0.173 0.663 IJ.9876 1.11126 0.523 1.477 0.516 1.459

22

0.640 0.167 0.647 0.9882 1.0119 0.5.14 1.466 0.528 1.448

23 0.626 0.162 0.633 0.9887 1.0114 0.545 1.455 0.539 1.438

24

0.612 0.157 0.619 ll.9892 1.0ll~J 0.555 1.445 0.5-19 1.4~9

25

0.600 0.153 0.606 0.989(1 J.0!05 0.565 1.435 0.559 1.4:!0

fodors ror

Center Linc

d,

J/d1

1.128 0.8865

1.693 0.5907

2.059 0.4857

2.326 0.4299

2.534 0.3946

2.7(1-1 0.3698

2.847 0.3512

2.970 0.3367

3.078 0.3249

3.173 0.3152

3.258 0.3069

3.336 0.2998

3.407 0.2935

3.472 0.2880

3.532 0.2831

3.588 0.2787

3.640 0.2747

3.(,89 0.2711

].735 0.2677

3.778 0.2647

3.819 0.2618

3.858 0.2592

3.895 0.2567

3.931 0.2544

Chart for R:lllj!l'S

Factors ror Contnll LhnUs

dJ o, o, DJ D,

0.853

0.888

0.880

0.86-1

0.848

0.833

0.820

0.808

0.797

0.787

0.778

0.770

0.763

0.756

0.750

0.7-14

0.739

0.734

0.729

0.724

0.720

0.716

0.712

0.708

0

3.686

0

4.358

0

4.698

0

4.918

0

5.078

0.2(1-1 5.2(1-1

(J.388 5.306

0.547 5.393

0.687 5.469

0.811 5.535

0.922 5.594

1.025 5.6-17

I.I 18 5.696

1.203 5.741

1.282 5.782

1.356 5.820

1.424 5.856

1.487 5.891

1.549 5.921

1.605 5.951

1.659 5.979

J.7)() 6.006

1.759 6.031

1.806 6.056

0

0

0

0

0

ll.076

0.136

0.184

0223

0.256

0.283

0.:307

0.328

0.347

0.363

0.378

0.391

0.403

0.415

0.425

0.434

0.-143

0.451

0.459

3.267

2.574

2.282

2.114

2.(JO.I

1.924

J.864

1.816

1.777

1.744

1.717

1.693

1.672

1.653

1.637

1.622

1.608

1597

1.585

1.575

1.566

1557

1.548

1.541

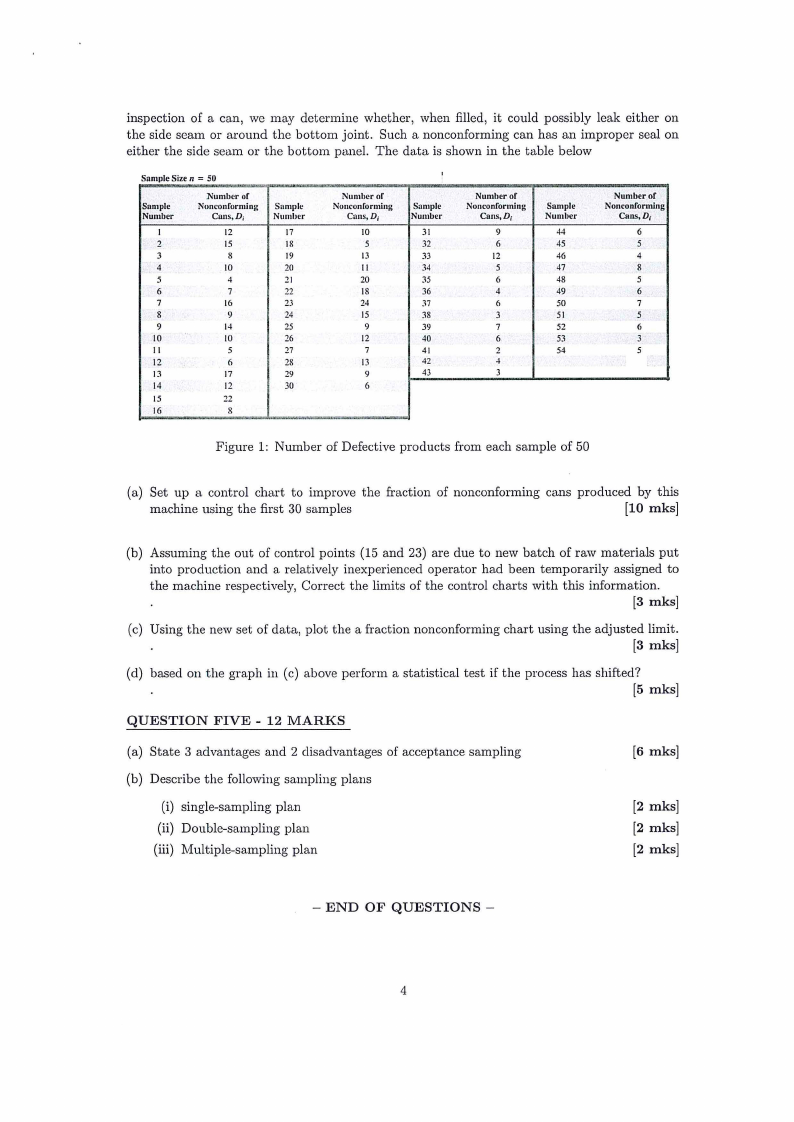

Figure 2: Factors for calculation of control charts

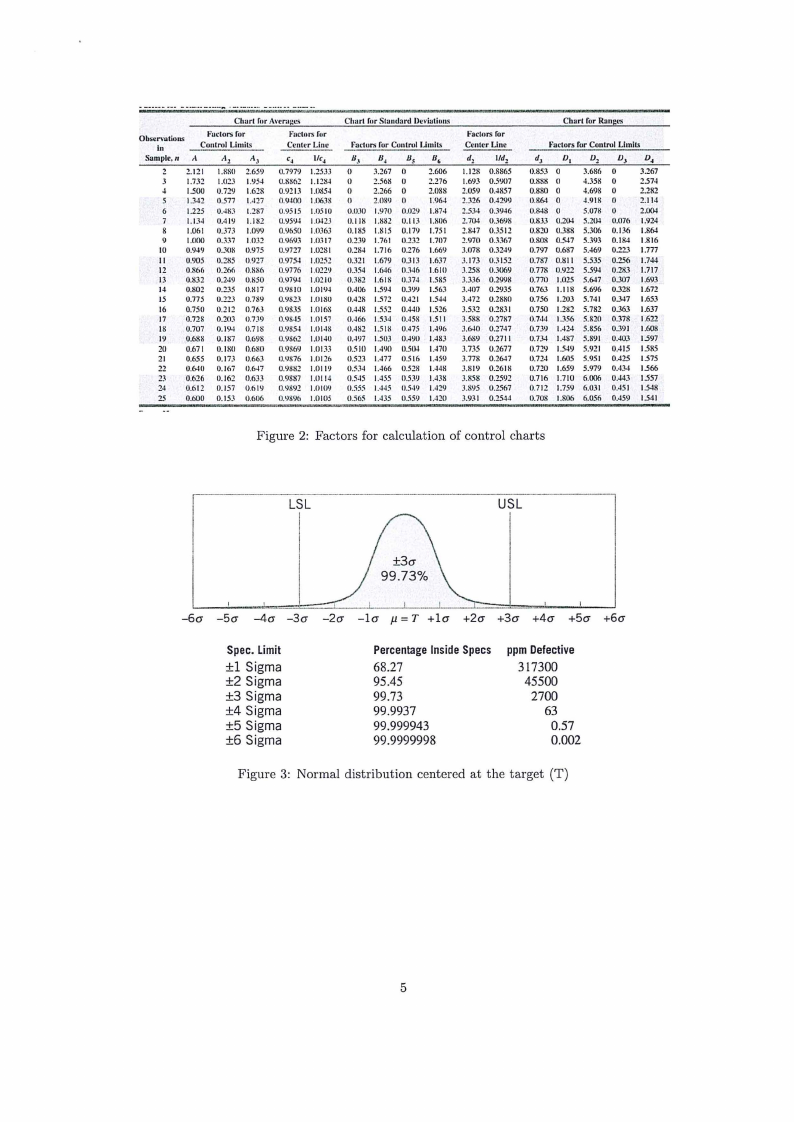

LSL

USL

-6a -5a -4a -3a -2a -la µ = T +la +2a +3a +4a +5a +6a

Spec.Limit

±1 Sigma

±2 Sigma

±3 Sigma

±4 Sigma

±5 Sigma

±6 Sigma

PercentageInsideSpecs ppmDefective

68.27

317300

95.45

45500

99.73

2700

99.9937

63

99.999943

0.57

99.9999998

0.002

Figure 3: Normal distribution centered at the target (T)

5

|

6 Page 6 |

▲back to top |

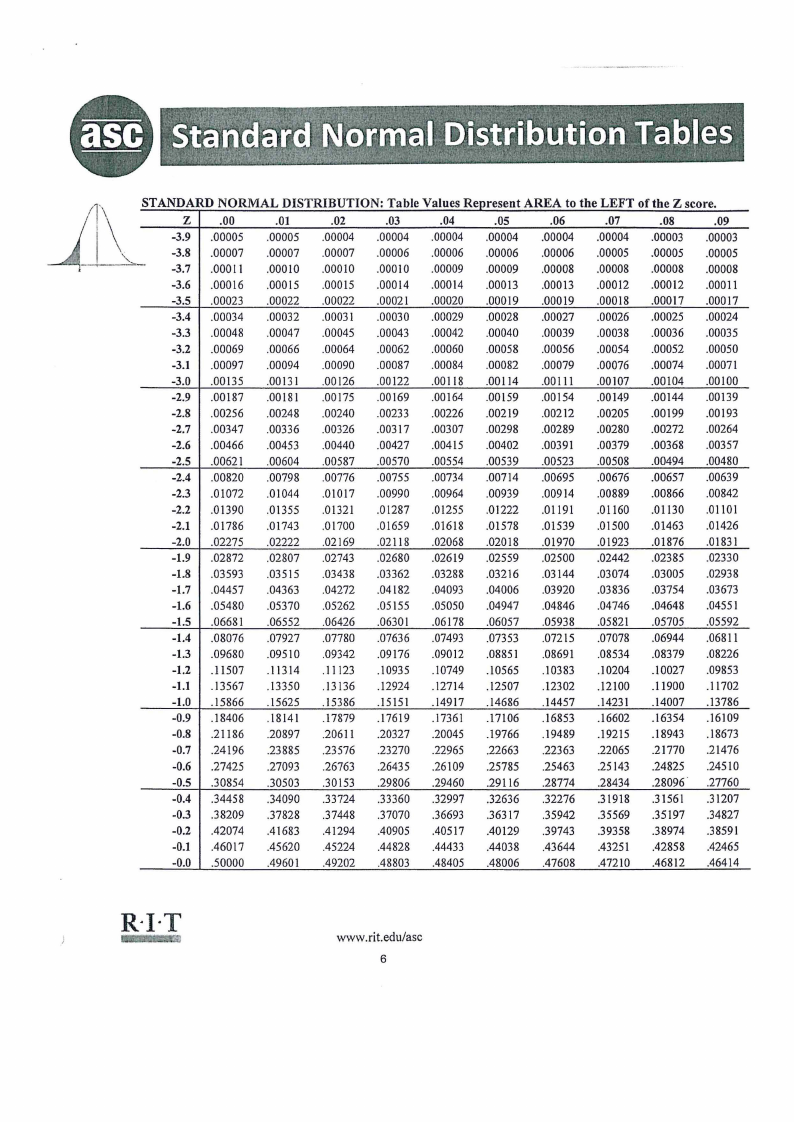

~TANDARD

NORMAL DISTRIBUTION : Table VIa ues Represent AREA tot he LEFT of the Z score.

z .00

.01

.02

.03

.04

.05

.06

.07

.08

.09

-3.9 .00005 .00005 .00004 .00004 .00004 .00004 .00004 .00004 .00003 .00003

-3.8 .00007 .00007 .00007 .00006 .00006 .00006 .00006 .00005 .00005 .00005

-3.7 .00011 .00010 .00010 .00010 .00009 .00009 .00008 .00008 .00008 .00008

-3.6 .00016 .00015 .00015 .00014 .00014 .00013 .00013 .00012 .00012 .00011

-3.5 .00023 .00022 .00022 .00021 .00020 .00019 .00019 .00018 .00017 .00017

-3.4 .00034 .00032 .00031 .00030 .00029 .00028 .00027 .00026 .00025 .00024

-3.3 .00048 .00047 .00045 .00043 .00042 .00040 .00039 .00038 .00036 .00035

-3.2 .00069 .00066 .00064 .00062 .00060 .00058 .00056 .00054 .00052 .00050

-3.1 .00097 .00094 .00090 .00087 .00084 .00082 .00079 .00076 .00074 .00071

-3.0 .00135 .00131 .00126 .00122 .00118 .00114 .00111 .00107 .00104 .00100

-2.9 .00187 .00181 .00175 .00169 .00164 .00159 .00154 .00149 .00144 .00139

-2.8 .00256 .00248 .00240 .00233 .00226 .00219 .00212 .00205 .00199 .00193

-2.7 .00347 .00336 .00326 .00317 .00307 .00298 .00289 .00280 .00272 .00264

-2.6 .00466 .00453 .00440 .00427 .00415 .00402 .00391 .00379 .00368 .00357

-2.S .00621 .00604 .00587 .00570 .00554 .00539 .00523 .00508 .00494 .00480

-2.4 .00820 .00798 .00776 .00755 .00734 .00714 .00695 .00676 .00657 .00639

-2.3 .01072 .01044 .01017 .00990 .00964 .00939 .00914 .00889 .00866 .00842

-2.2 .01390 .01355 .01321 .01287 .01255 .01222 .01191 .01160 .01130 .01101

-2.1 .01786 .01743 .01700 .01659 .01618 .01578 .01539 .01500 .01463 .01426

-2.0 .02275 .02222 .02169 .02118 .02068 .02018 .01970 .01923 .01876 .01831

-1.9 .02872 .02807 .02743 .02680 .02619 .02559 .02500 .02442 .02385 .02330

-1.8 .03593 .03515 .03438 .03362 .03288 .03216 .03144 .03074 .03005 .02938

-1.7 .04457 .04363 .04272 .04182 .04093 .04006 .03920 .03836 .03754 .03673

-1.6 .05480 .05370 .05262 .05155 .05050 .04947 .04846 .04746 .04648 .04551

-1.5 .06681 .06552 .06426 .06301 .06178 .06057 .05938 .05821 .05705 .05592

-1.4 .08076 .07927 .07780 .07636 .07493 .07353 .07215 .07078 .06944 .06811

-1.3 .09680 .09510 .09342 .09176 .09012 .08851 .08691 .08534 .08379 .08226

-1.2 .11507 .11314 .11123 .10935 .10749 .10565 .10383 .10204 .10027 .09853

-1.1 .13567 .13350 .13136 .12924 .12714 .12507 .12302 .12100 .11900 .11702

-1.0 .15866 .15625 .15386 .15151 .14917 .14686 .14457 .14231 .14007 .13786

-0.9 .18406 .18141 .17879 .17619 .17361 .17106 .16853 .16602 .16354 .16109

-0.8 .21186 .20897 .20611 .20327 .20045 .19766 .19489 .19215 .18943 .18673

-0.7 .24196 .23885 .23576 .23270 .22965 .22663 .22363 .22065 .21770 .21476

-0.6 .27425 .27093 .26763 .26435 .26109 .25785 .25463 .25143 .24825 .24510

-0.5 .30854 .30503 .30153 .29806 .29460 .29116 .28774 .28434 .28096' .27760

-0.4 .34458 .34090 .33724 .33360 .32997 .32636 .32276 .31918 .31561 .31207

-0.3 .38209 .37828 .37448 .37070 .36693 .36317 .35942 .35569 .35197 .34827

-0.2 .42074 .41683 .41294 .40905 .40517 .40129 .39743 .39358 .38974 .38591

-0.1 .46017 .45620 .45224 .44828 .44433 .44038 .43644 .43251 .42858 .42465

-0.0 .50000 .49601 .49202 .48803 .48405 .48006 .47608 .47210 .46812 .46414

R·I·T

www.rit.edu/asc

6

|

7 Page 7 |

▲back to top |

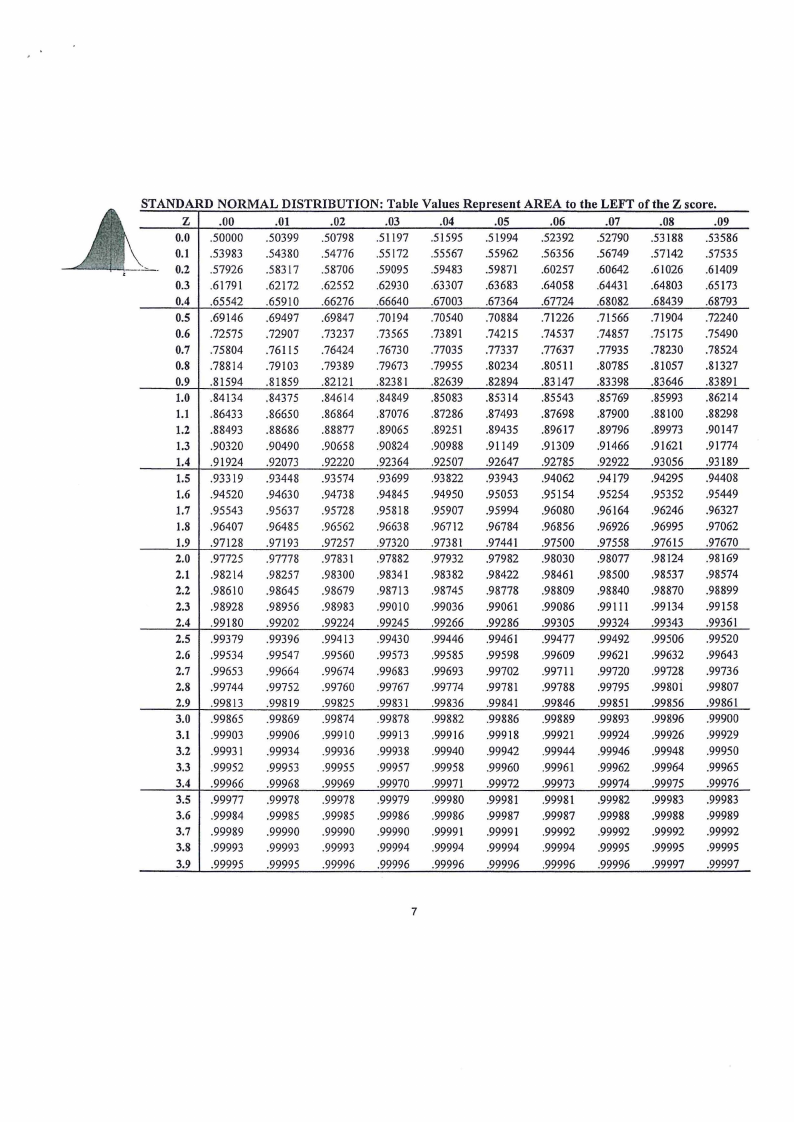

STANDARD NORMAL DISTRIBUTION : Table VaIucs R eprcsen t AREA t0 the LEFT 0 fth e Z score .

z .00

.01

.02

.03

. 04

.05

.06

.07

.08

.09

0.0 .50000 .50399 .50798 .51197 .51595 .51994 .52392 .52790 .53188 .53586

0.1 .53983 .54380 .54776 .55172 .55567 .55962 .56356 .56749 .57142 .57535

-'>-. 0.2 .57926 .58317 .58706 .59095 .59483 .59871 .60257 .60642 .61026 .61409

0.3 .61791 .62172 .62552 .62930 .63307 .63683 .64058 .64431 .64803 .65173

0.4 .65542 .65910 .66276 .66640 .67003 .67364 .67724 .68082 .68439 .68793

0.5 .69146 .69497 .69847 .70194 .70540 .70884 .71226 .71566 .71904 .72240

0.6 .72575 .72907 .73237 .73565 .73891 .74215 .74537 .74857 .75175 .75490

0.7 .75804 .76115 .76424 .76730 .77035 .77337 .77637 .77935 .78230 .78524

0.8 .78814 .79103 .79389 .79673 .79955 .80234 .80511 .80785 .81057 .81327

0.9 .81594 .81859 .82121 .82381 .82639 .82894 .83147 .83398 .83646 .83891

1.0 .84134 .84375 .84614 .84849 .85083 .85314 .85543 .85769 .85993 .86214

1.1 .86433 .86650 .86864 .87076 .87286 .87493 .87698 .87900 .88100 .88298

1.2 .88493 .88686 .88877 .89065 .89251 .89435 .89617 .89796 .89973 .90147

1.3 .90320 .90490 .90658 .90824 .90988 .91149 .91309 .91466 .91621 .91774

1.4 .91924 .92073 .92220 .92364 .92507 .92647 .92785 .92922 .93056 .93189

1.5 .93319 .93448 .93574 .93699 .93822 .93943 .94062 .94179 .94295 .94408

1.6 .94520 .94630 .94738 .94845 .94950 .95053 .95154 .95254 .95352 .95449

1.7 .95543 .95637 .95728 .95818 .95907 .95994 .96080 .96164 .96246 .96327

1.8 .96407 .96485 .96562 .96638 .96712 .96784 .96856 .96926 .96995 .97062

1.9 .97128 .97193 .97257 .97320 .97381 .97441 .97500 .97558 .97615 .97670

2.0 .97725 .97778 .97831 .97882 .97932 .97982 .98030 .98077 .98124 .98169

2.1 .98214 .98257 .98300 .98341 .98382 .98422 .98461 .98500 .98537 .98574

2.2 .98610 .98645 .98679 .98713 .98745 .98778 .98809 .98840 .98870 .98899

2.3 .98928 .98956 .98983 .99010 .99036 .99061 .99086 .99111 .99134 .99158

2.4 .99180 .99202 .99224 .99245 .99266 .99286 .99305 .99324 .99343 .99361

2.5 .99379 .99396 .99413 .99430 .99446 .99461 .99477 .99492 .99506 .99520

2.6 .99534 .99547 .99560 .99573 .99585 .99598 .99609 .99621 .99632 .99643

2.7 .99653 .99664 .99674 .99683 .99693 .99702 .99711 .99720 .99728 .99736

2.8 .99744 .99752 .99760 .99767 .99774 .99781 .99788 .99795 .99801 .99807

2.9 .99813 .99819 .99825 .99831 .99836 .99841 .99846 .99851 .99856 .99861

3.0 .99865 .99869 .99874 .99878 .99882 .99886 .99889 .99893 .99896 .99900

3.1 .99903 .99906 .99910 .99913 .99916 .99918 .99921 .99924 .99926 .99929

3.2 .99931 .99934 .99936 .99938 .99940 .99942 .99944 .99946 .99948 .99950

3.3 .99952 .99953 .99955 .99957 .99958 .99960 .99961 .99962 .99964 .99965

3.4 .99966 .99968 .99969 .99970 .99971 .99972 .99973 .99974 .99975 .99976

3.5 .99977 .99978 .99978 .99979 .99980 .99981 .99981 .99982 .99983 .99983

3.6 .99984 .99985 .99985 .99986 .99986 .99987 .99987 .99988 .99988 .99989

3.7 .99989 .99990 .99990 .99990 .99991 .99991 .99992 .99992 .99992 .99992

3.8 .99993 .99993 .99993 .99994 .99994 .99994 .99994 .99995 .99995 .99995

3.9 .99995 .99995 .99996 .99996 .99996 .99996 .99996 .99996 .99997 .99997

7