|

MPC711S - Mineral Separation Process 314 - 1st OPP - JUN 2023 |

|

1 Page 1 |

▲back to top |

n Am I BI A u n IVER s ITY

OF SCIEnCE

TECHnOLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CIVIL, MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY, CHEMICAL ENGINEERING &

MINING ENGINEERING

QUALIFICATION CODE:

08BEMT /08BECE/08BM EG

LEVEL: 7

COURSE CODE: MPC711S

COURSE NAME: MINERAL SEPARATION PROCESSES

314

SESSION: JUNE 2023

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

FIRST OPPORTUNITY QUESTION PAPER

Dr Clement Kwasi Owusu

MODERATOR:

Prof. Godfrey Dzinomwa

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

2. Non-programmable calculator

|

2 Page 2 |

▲back to top |

Question 1

(25Marks)

Rosh Pinah ore sample was floated using the Magotteaux laboratory flotation to

produce lead and zinc concenh·ate. The outcome of the laboratory flotation test after

assaying is presented in the Table below. Calculate;

i. the recovery of Pb in copper concentrate

(5 marks)

ii. the recovery of Zn in zinc concentrate

(5 marks)

iii. the tonnage (tph) of the lead concenh·ate

(5 marks)

iv. the tonnage (tph) of the zinc concenh·ate

(5 marks)

v. the tonnage (tph) tailings

(5 marks)

Sh·eam

Feed

Pb concenh·ate

Zn concenh·ate

Tailings

Throughput (tph)

150

-

-

-

Pb(%)

5.7

50.3

0.2

0.15

Assay

Zn(%)

4.3

2.1

60.7

0.10

Question 2

(20 marks)

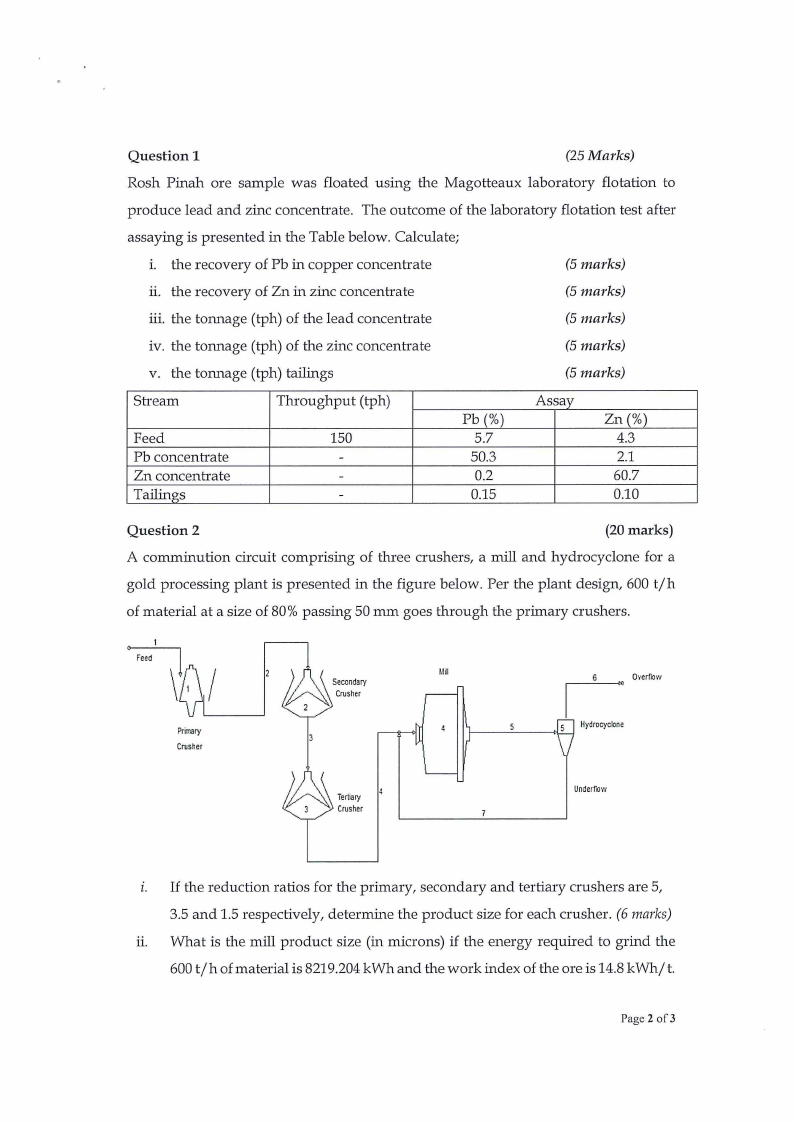

A comminution circuit comprising of three crushers, a mill and hydrocyclone for a

gold processing plant is presented in the figure below. Per the plant design, 600 t/h

of material at a size of 80% passing 50 mm goes through the primary crushers.

1

\\QI

Primary

Crusher

l,lill

Crusher

6

I

Overflow

5 Hydrocyclone

Tertiary

Crusher

Underflow

z. If the reduction ratios for the primary, secondary and tertiary crushers are 5,

3.5 and 1.5 respectively, determine the product size for each crusher. (6 marks)

ii. What is the mill product size (in microns) if the energy required to grind the

600 t/h of material is 8219.204kWh and the work index of the ore is 14.8 kWh/t.

Page 2 of3

|

3 Page 3 |

▲back to top |

(Assume that cyclone underflow has the same size as the tertiary crusher

product)?

(10 marks)

ill. If the circulating load is 25%, estimate the mass for cyclone overflow and

underflow.

(4 marks)

Question 3

(26 marks)

a. Briefly explain the impact of the following on screen performance

z. Percentage near mesh particles

(3 marks)

zz. Moisture content of feed

(3 marks)

m. Feed rate

(3 marks)

b. Mention two areas in minerals processing where hydrocyclones are widely

used as a classifier

(4 marks)

c. Mention two advantages of dense medium separation

(5 marks)

d. Calculate the mass of water in tonnes required to be added to 48.2 tonnes of

ferrosilicon compound to make a slurry of pulp density of 2.92 t/m 3. Assume

the density of ferrosilicon compound is 7.0 t/m 3 and that of water is 1 t/m 3·

(8 marks)

Question4

(29 marks)

a. Explain the terms rougher cell, scavenger cell and cleaner cell as applied in

flotation

(9 marks)

1. A single cell in a given bank of flotation cells gives a Copper recovery of

45% for a residence time of 5 minutes. Find the number of similar sized

cells in a continuous flotation bank that would give a total recovery of

93%.

(6 marks)

b. Explain the subaqueous deposition method as applied in tailings management.

(4 marks)

ii. Mention 3 possible causes for tailings dam failure.

(6 marks)

c. Explain the relevance of gravity take-up pulley in conveyor belt system

(4 marks)

THIS QUESTION PAPER CONSISTS OF 3 PAGES (Including this front page)

Page 3 of3