|

RMC711S - Rock Mechanics 314 - 1st Opp - June 2022 |

|

1 Page 1 |

▲back to top |

nAmI BIA un IVERSITY

OFSCIEnCEAno TECHnOLOGY

FACULTY OF ENGINEERING AND SPATIAL SCIENCE

DEPARTMENT OF MINING AND PROCESS ENGINEERING

QUALIFICATION: BACHELORS OF ENGINEERING IN MINING ENGINEERING

QUALIFICATION CODE: BEMIN LEVEL: 6

COURSE CODE: RMC711S

COURSE NAME: ROCK MECHANICS

SESSION: JUNE 2022

PAPER: THEORY

DURATION: 3 HOURS

MARKS: 100

FIRST OPPORTUNITY QUESTION PAPER

EXAMINER(S) Mallikarjun Rao Pillalamarry

MODERATOR: Prof. Mapani Benjamin

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

2. Two Graph Papers

3. Mathematical Instruments

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

|

3 Page 3 |

▲back to top |

Instructions: Answer Question 1 and any 4 other questions. Excess questions will not be marked.

Question 1 is compulsory.

Time allowed: 3 hours

Question 1 Short answer questions

(20)

a) What the difference between rock and rock mass?

b) What is the range of 'Q' value in 'Q' classification system?

c) What is the maximum length of drill core run used to measure RQD?

d) How do the water in the joints influence the stability of rock mass?

e) Which side the Mohr's circle moves when pore pressure is increased?

f) What are the parameters associated with Bieniawski's RMR?

g) Direction of major principal stress for a rock is 35° from x-axis. What is the major shear

stress direction with respect to y-axis [both x, y-axes are perpendicular to each other]

h) RQD is the first quantitative rock mass classification system developed by John Deer [ 1964].

Nevertheless, it has two major problems with respect to rock mass classification, what are

they?

i) In triaxial testing, which of confining stress and axial stress, is constant?

j) Shear strength failure criteria for a rock sample is 't = 25+ O"nTan 23.6°, then what is the

angle between failure plane and major principal stress direction? [2]

Question 2 Briefly discuss the following characteristics of discontinuities and their effect on stability (20)

of rockmass with diagrams wherever possible

a) Joint spacing

b) Joint orientation

c) Fracture aperture

d) Fracture roughness

e) Fracture filling

Question 3 A competent sandstone rock mass is fractured by three joint sets plus random fractures. The (20)

average RQD is 75%; the average joint spacing is 0.18 m. The joint surfaces are slightly

rough and slightly weathered. The joints are in contact with apertures generally less than 1

mm; no clay is found on the surfaces. The point load strength index of the sandstone is 3.5

MPa. The tunnel is to be excavated at 50 m below the ground level and the ground water

table is 20 m below the ground surface, thus large inflow of water expected. Estimate the Q-

value.

Question 4

a) What are methods used to measure in situ stresses and classify them according to the amount (6)

of disturbance caused during measurement

b) Briefly describe with help of figures, in situ stress measurement using flatjack method

(14)

|

4 Page 4 |

▲back to top |

|

5 Page 5 |

▲back to top |

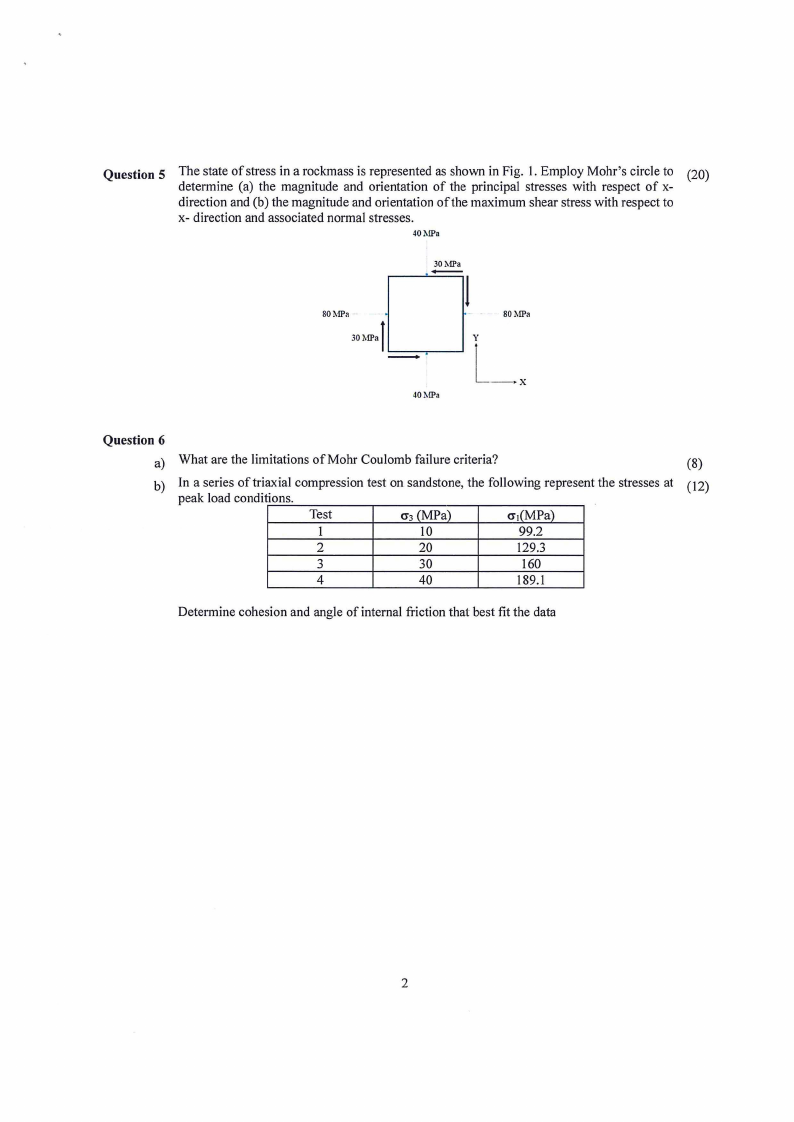

Question 5 The state of stress in a rockmass is represented as shown in Fig. I. Employ Mohr's circle to (20)

determine (a) the magnitude and orientation of the principal stresses with respect of x-

direction and (b) the magnitude and orientation of the maximum shear stress with respect to

x- direction and associated normal stresses.

40MPa

30MPa

80MPa -

l-30MPa

40MPa

-

80MPa

YL,

Question 6

a) What are the limitations of Mohr Coulomb failure criteria?

(8)

b) In a series of triaxial compression test on sandstone, the following represent the stresses at ( 12)

peak load conditions.

Test

cr3(MPa)

cri(MPa)

1

IO

99.2

2

20

129.3

3

30

160

4

40

189.l

Determine cohesion and angle of internal friction that best fit the data

2

|

6 Page 6 |

▲back to top |

|

7 Page 7 |

▲back to top |

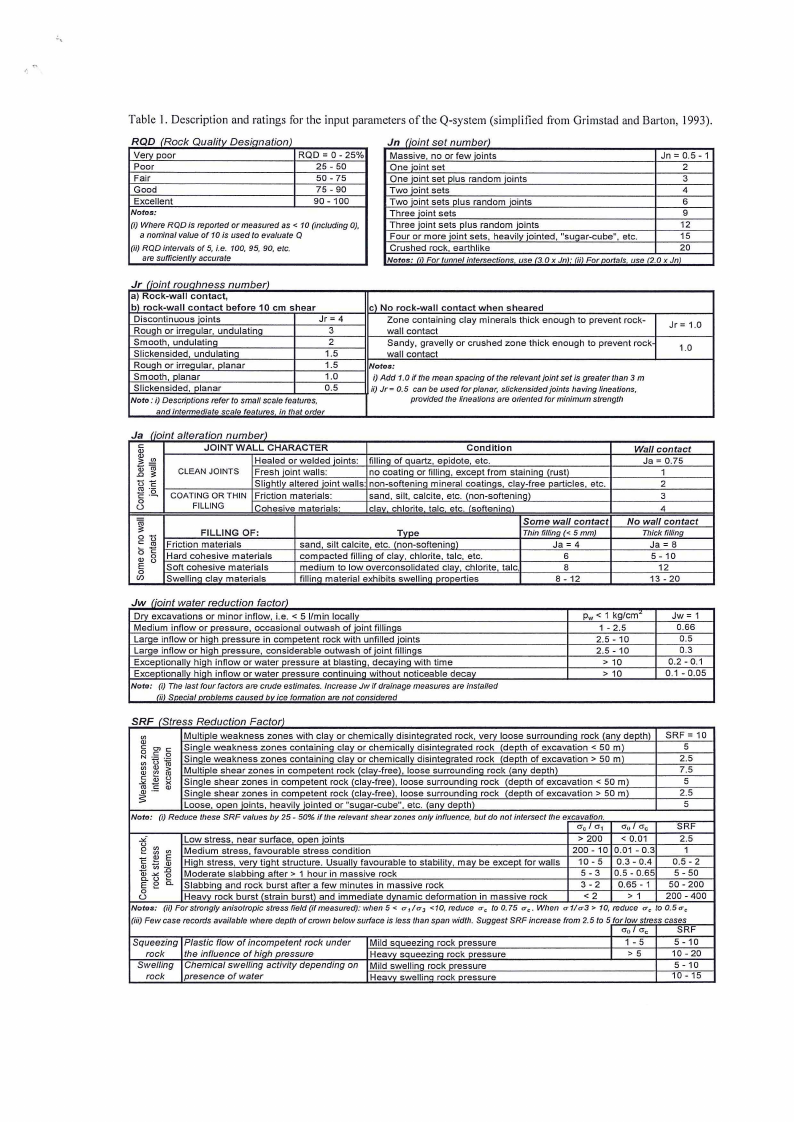

Table I. Description and ratings for the input parameters of the Q-system (simplified from Grimstad and Barton, 1993).

RQD /Rock Qualitv Oesiqnation)

Very poor

ROD= 0 -25%

Poor

Fair

Good

Excellent

Notos:

25 - 50

50 - 75

75 - 90

90 - 100

(i) Where ROD is reported or measured as < 10 (including OJ,

a nominal value of 10 is used to evaluate O

(ii) ROD intervals of 5, i.e. 100, 95, 90, etc.

are sufficiently accurate

Jn (joint set number)

Massive, no or few joints

Jn=0.5-1

One joint set

2

One joint set plus random joints

3

Two joint sets

4

Two joint sets plus random joints

6

Three joint sets

9

Three joint sets plus random joints

12

Four or more joint sets, heavily jointed, "suoar-cube", etc.

15

Crushed rock, earthlike

20

Notos: (iJ For tunnel intersections use (3. Ox Jn); (ii) For oortals, use (2.0 x Jn)

Jr (ioint rouahness number)

a) Rock-wall contact,

b) rock-wall contact before 10 cm shear

Discontinuous joints

Jr= 4

Rough or irregular, undulating

3

Smooth, undulating

2

Slickensided, undulating

1.5

Rough or irregular, planar

1.5

Smooth, planar

1,0

Slickensided, planar

0.5

Noto. i) Descriptions refer to small scale features,

and intermediate scale features in that order

cl No rock-wall contact when sheared

Zone containing clay minerals thick enough to prevent rock-

wall contact

Sandy, gravelly or crushed zone thick enough to prevent rock

wall contact

Notos:

i) Add 1.Oif the mean spacing of the relevant joint setis greater than 3 m

ii) Jr= o. 5 can be used for planar. slickensided joints having lineations,

provided the lineations are oriented for minimum strength

Jr= 1.0

1.0

Ja (joint alteration number)

c..:,,:

JOINT WALL CHARACTER

Condition

3: .!!!

ID

.0

C3O:

Healed or welded ioints: fillino of auartz, epidote, etc.

CLEAN JOINTS Fresh joint walls:

no coatina or fillina, except from stainina (rust)

t5 C:

Sliahtly altered joint walls: non-softenina mineral coatinas, clay-free oarticles, etc.

"'C: :2. COATING OR THIN Friction materials:

sand, silt, calcite, etc. (non-softening)

0

()

FILLING

Cohesive materials:

clav. chlorite talc etc. /softeninal

ro

3:

0c:: t5

"' 0 C:

0

., (.)

E

0

Cf)

FILLING OF:

Friction materials

Hard cohesive materials

Soft cohesive materials

Swellina clav materials

Some wall contact

Type

Thin filling{< 5 mm)

sand, silt calcite, etc. (nan-softening)

Ja = 4

compacted filling of clay, chlorite, talc, etc.

6

medium to low overcansolidated clay, chlorite, talc,

8

fillino material exhibits swellina orooerties

8 - 12

Wall contact

Ja = 0.75

1

2

3

4

No wall contact

Thick filling

Ja = 8

5 - 10

12

13 - 20

Jw fioint water reduction factor)

Drv excavations or minor inflow, i.e. < 5 I/min locally

Medium inflow or pressure, occasional outwash of joint fillings

Large inflow or high pressure in competent rock with unfilled joints

Large inflow or high pressure, considerable outwash of joint fillings

Exceptionally high inflow or water pressure at blasting, decaying with time

Exceptionally high inflow or water pressure continuing without noticeable decay

Noto: (i) The last four factors are crude estimates. Increase Jw if drainage measures are installed

/iii Snecial nroblems caused bv ice formation are not considered

Pw< 1 kg/cm'

1 - 2,5

2,5 - 10

2.5 - 10

> 10

> 10

Jw= 1

0.66

0.5

0.3

0.2 - 0.1

0.1 -0,05

SRF /Stress Reduction Factor)

.,V)

c::

0

N

"c':: c0::

V)

V)

., ., c::

(.)

"' ., -"' ,-e, X

Multiole weakness zones with clay or chemically disintearated rock, verv loose surrounding rock (any deothl

Sinale weakness zones containing clay or chemically disintegrated rock (death of excavation< 50 ml

Sinale weakness zones containina clav or chemicallv disintearated rock (depth of excavation> 50 ml

Multiole shear zones in comoetent rock /clav-freel, loose surroundina rock (anv deothl

Sinale shear zones in comoetent rock (clay-freel, lease surroundina rock (death of excavation < 50 m)

Sinale shear zones in comoetent rock (clay-free). loose surroundina rock (death of excavation> 50 m)

Loose, ooen ioints, heavilv iointed or "suaar-cube", etc. (anv death)

SRF = 10

5

2.5

7.5

5

2.5

5

Noto: (i) Reduce these SRF values by 25 - 50% if the relevant shear zones only influence, but do not intersect the excavation.

O'c I cr1

O'o I O'c

-""(.)

V)

e V)

V)

-

2C

!.:,:

E

Q)

V, :0

., -"' 0

e C. (.)

E

C.

0

()

Low stress, near surface, ooen ioints

Medium stress, favourable stress condition

Hiah stress, verv tiaht structure. Usuallv favourable to stabilitv, may be except for walls

Moderate slabbino after> 1 hour in massive rock

Slabbina and rock burst after a few minutes in massive rock

Heavy rock burst (strain burst) and immediate dynamic deformation in massive rock

> 200 < 0.01

200 - 10 0.01 - 0.3

10 - 5 0.3 - 0.4

5-3 0,5 - 0,65

3-2

0.65 - 1

<2

>1

SRF

2.5

1

0.5 - 2

5 - 50

50 - 200

200 - 400

Notos: (ii) For strongly anisotropic stress field (if measured): when 5 < a-1/a- 3 <10, reduce a-, to 0.75 a-,. When a-1/a-3 > 10, reduce a-, to 0.5 a-,

(iii) Few case records available where depth of crown below surface is less than span width. Suggest SRF increase from 2. 5 to 5 for low stress cases

O'o I O'c

SRF

Squeezing

rock

Swelling

rock

Plastic flow of incompetent rock under

the influence of high pressure

Chemical swelling activity depending on

presence of water

Mild saueezinq rock pressure

Heavv saueezinq rock pressure

Mild swellinq rock pressure

Heavv swellinq rock pressure

1- 5

>5

5 - 10

10 - 20

5 - 10

10 - 15

|

8 Page 8 |

▲back to top |