|

FFR820S - Fuel Furnaces and Refractories - 2nd OPP - JUN 2023 |

|

1 Page 1 |

▲back to top |

1

nAmlBIA UnlVERSITY

OF SCIEnCEAno TECHnOLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CIVL, MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELORSOF ENGINEERINGIN MINING ENGINEERING

QUALIFICATIONCODE: 08BMEG

LEVEL: 8

COURSECODE: FFR820S

COURSENAME: FUELSFURNACESAND

REFRACTORIES

SESSION:JUNE 2023

PAPER:THEORY

DURATION: 3 HOURS

MARKS: 60

SECOND OPPORTUNITY QUESTIONS

EXAMINER(S) Maweja Kasonde

MODERATOR: Prof. Vusumuzi Sibanda

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

2. Calculator

THIS QUESTION PAPERCONSISTSOF 3 PAGES(Including this front page)

|

2 Page 2 |

▲back to top |

2

Question 1

(max 8)

Basic furnace control strategies are based on either the product temperature control or the

fuzzy logic and rule-based systems. Give summary principles of the two control strategies.

Question 2

(max 8)

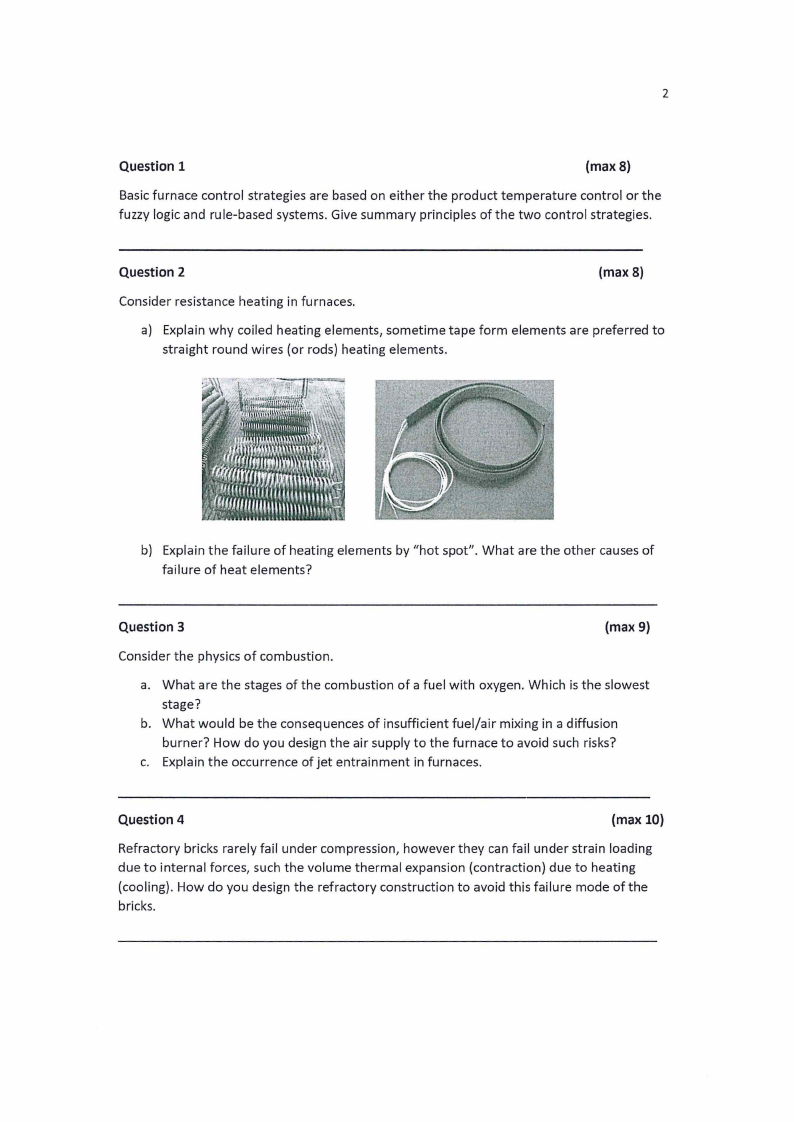

Consider resistance heating in furnaces.

a) Explain why coiled heating elements, sometime tape form elements are preferred to

straight round wires (or rods) heating elements.

b) Explain the failure of heating elements by "hot spot". What are the other causes of

failure of heat elements?

Question 3

(max 9)

Consider the physics of combustion.

a. What are the stages of the combustion of a fuel with oxygen. Which is the slowest

stage?

b. What would be the consequences of insufficient fuel/air mixing in a diffusion

burner? How do you design the air supply to the furnace to avoid such risks?

c. Explain the occurrence of jet entrainment in furnaces.

Question 4

(max 10)

Refractory bricks rarely fail under compression, however they can fail under strain loading

due to internal forces, such the volume thermal expansion (contraction) due to heating

(cooling). How do you design the refractory construction to avoid this failure mode of the

bricks.

|

3 Page 3 |

▲back to top |

3

Question 5

(max 10)

Discuss the effect of the electric courant frequency on the careless and cored designs and

operation conditions of induction furnaces. Fully explain the effect on the heating depth.

p =.2._ cm

2TT

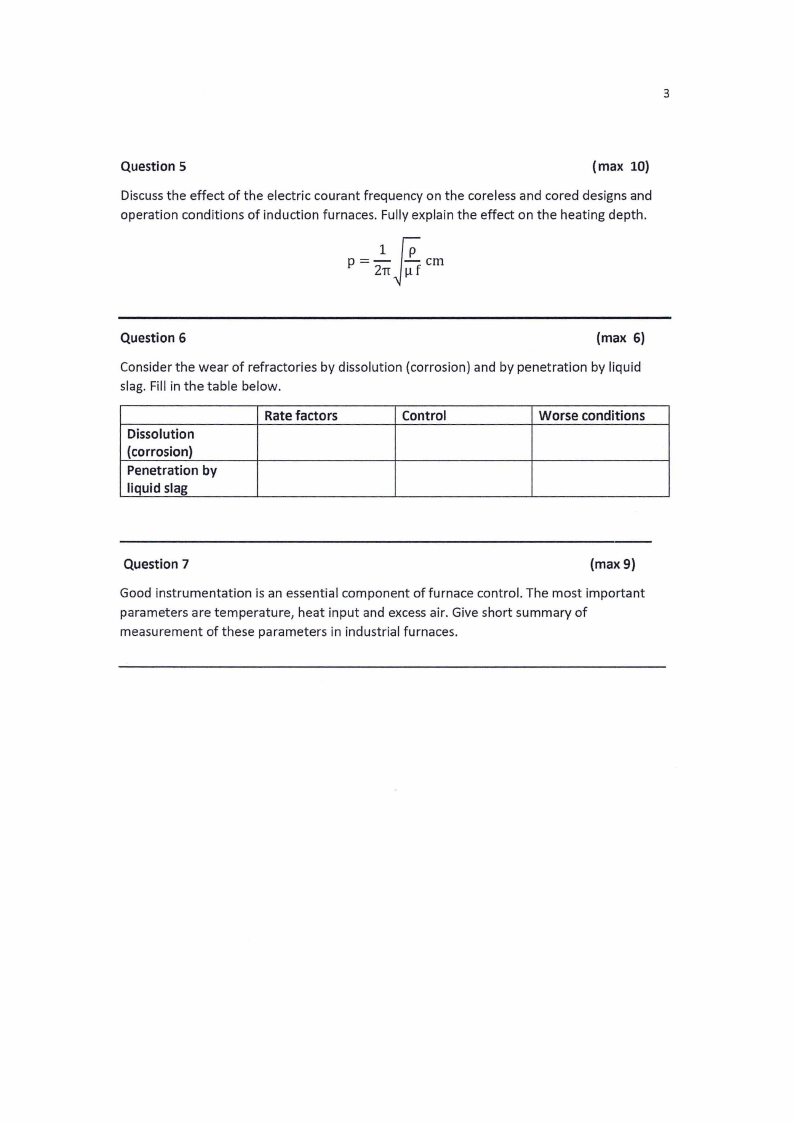

Question 6

(max 6)

Consider the wear of refractories by dissolution (corrosion) and by penetration by liquid

slag. Fill in the table below.

Dissolution

(corrosion)

Penetration by

liquid slag

Rate factors

Control

Worse conditions

Question 7

(max 9)

Good instrumentation is an essential component of furnace control. The most important

parameters are temperature, heat input and excess air. Give short summary of

measurement of these parameters in industrial furnaces.