|

RMC711S - Rock Mechanics - 2nd OPP - june 2023 |

|

1 Page 1 |

▲back to top |

nAmlBIA UnlVERSITY

OF SCIEnCE Ano TECHnOLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CIVL, MINING AND PROCESS ENGINEERING

QUALIFICATION: BACHELORS OF ENGINEERING IN MINING ENGINEERING

QUALIFICATION CODE: 08BMEG LEVEL: 7

COURSE CODE: RMC711S

COURSE NAME: ROCK MECHANICS

SESSION: JUNE 2023

PAPER: THEORY

DURATION: 2.5 HOURS

MARKS:80

SECOND OPPORTUNITY QUESTION PAPER

EXAMINER(S) Mallikarjun Rao Pillalamarry

MOD ERA TOR: Prof. Mapani Benjamin

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

I. Examination paper.

2. Tracing Papers

3. Mathematical Instruments

THIS QUESTION PAPER CONSISTS OF 6 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

Instructions: Answer all questions.

Time allowed: 2.5 hours

Question 1 State of stress at a point in undergound is given below. Estimate the principal stresses and (20)

their directions.

CTxx

20.5MPa CTxv

-2.4 MPa

CTvv

34.8 MPa CTvz

-8.0 MPa

CTzz

8.1 MPa CTzx

5.2 MPa

a) Draw stress diagram (free body diagram) and indicate the stresses on it [5]

b) If the minor principal stress is 4.45 MPa, determine minor principal stress direction

with respect to X, Y and Z axis. [ 15]

Question 2

a) Briefly discuss the need for rockmass classification system

(6)

b) A 15 m span crusher for an underground mine is to be excavated in a granitic rock at a depth ( 14)

of 1500 m below the surface. The rockrnass contains two sets of joints. These joints are

undulating, rough and unweathered with very minor surface staining. RQD values range

from 85% to 95% and laboratory test on core samples of intact rock give an average uni axial

compressive strength of200 MPa. The principal stress directions are approximately vertical

and horizontal, and the magnitude of horizontal principal stress is approximately 1.5 times

that of the vertical principal stress. The rockrnass is locally damp but there is no evidence of

flowing water. Discuss the support requirements of the above excavation. Average unit

weight of the rockrnass is 26 kN/m3.

Question 3

a) What parameters are used to characterise fractures/joints in a rockrnass?

(IO)

b) Two lines of having dip direction/dip 140/60 and 235/30 are known to lie in the same plane. (15)

Determine

1. The dip direction and dip of the common plane [10]

11. Internal angle between the two lines [5]

Question 4

a) Compare the soft and stiff testing machine and their influence on the post peak stress-strain (10)

curve with an example.

b) Briefly describe in-situ stress measurement using the Flactjack method with the help of (IO)

figures.

2

|

3 Page 3 |

▲back to top |

ADDITIONAL INFORMATION

RMC711S June/July Exam

Angle stress marking with x, y, and z axis

A=

CTyy -cr1

I CTyz

I CTyz

CTzz- CT1

I B=- CTxy

CTyz

I CTzx CTzz- CT1

= C ICTxy CTyy -cr11

CTzx

CTyz

|

4 Page 4 |

▲back to top |

Short on the Q-system

The Q-system for rock mass classification, developed at the Norwegian Geotechnical Institute (NGI) in 1974,

originally included a little more than 200 tunnel case histories, mainly from Scandinavia (Baiton et al.,

1974). In 1993 the system was updated to include more than 1000 cases (Grimstad and Barton, 1993). It is a

quantitative classification system for estimates of tunnel support, based on a numerical assessment of the

rock mass quality using the following six parameters:

• Rock quality designation (RQD).

• Number of joint sets (111).

• Roughness of the most unfavourable joint or discontinuity (Jr)-

• Degree of alteration or filling along the weakest joint (J.).

• Water inflow (J,v).

• Stress condition given as the stress reduction factor (SRF); composed of

- Loosening load in the case of shear zones and clay bearing rock,

- Rock stress in competent rock, and

Squeezing and swelling loads in plastic, incompetent rock.

The above six parameters are grouped into three quotients to give the overall rock mass quality:

• The first two parameters represent the overall structure of the rock mass, and their quotient is a relative

measure of the block size.

• The second quotient is described as an indicator of the inter-block shear strength.

• The third quotient is described as the "active stresses".

The ratings of the various input parameters to the Q-value are given in Table I.

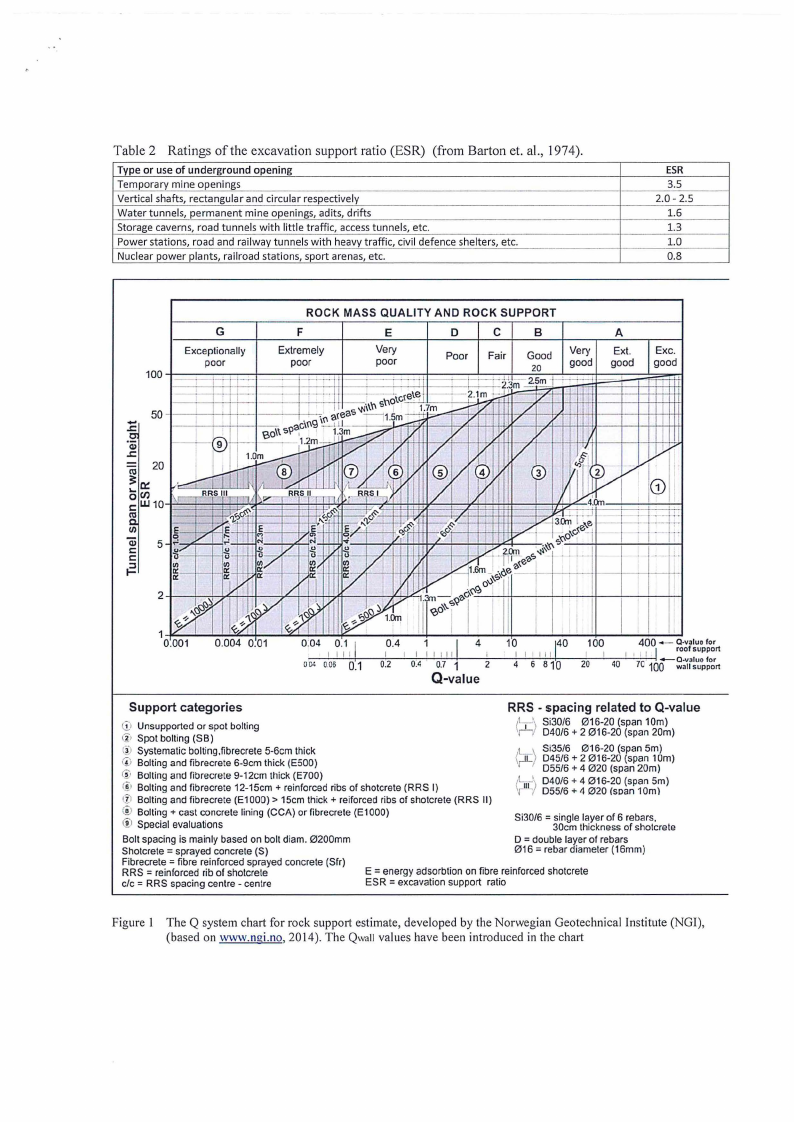

The Q-value is related to tunnel support requirement by defining the equivalent dimensions of the

underground opening. This equivalent dimension, which is a function of the size and type of the excavation,

is obtained by dividing the span, diameter or wall height of the excavation (Dt) by a quantity called the

excavation support ratio (ESR), given as:

De = _.!2_!_

ESR

Ratings of ESR are shown in Table 2

The Q-value in Figure I is related to the total amount of support (temporary and permanent) in the roof. The

diagram is based on numerous tunnel support cases. Wall support can also be found using the same figure by

applying the wall height and the following adjustments to Q:

For Q > 10

For 0.1 < Q < 10

use Qwall= 5Q

use Qwall= 2.5Q

For Q < 0.1

use Qwall= Q

|

5 Page 5 |

▲back to top |

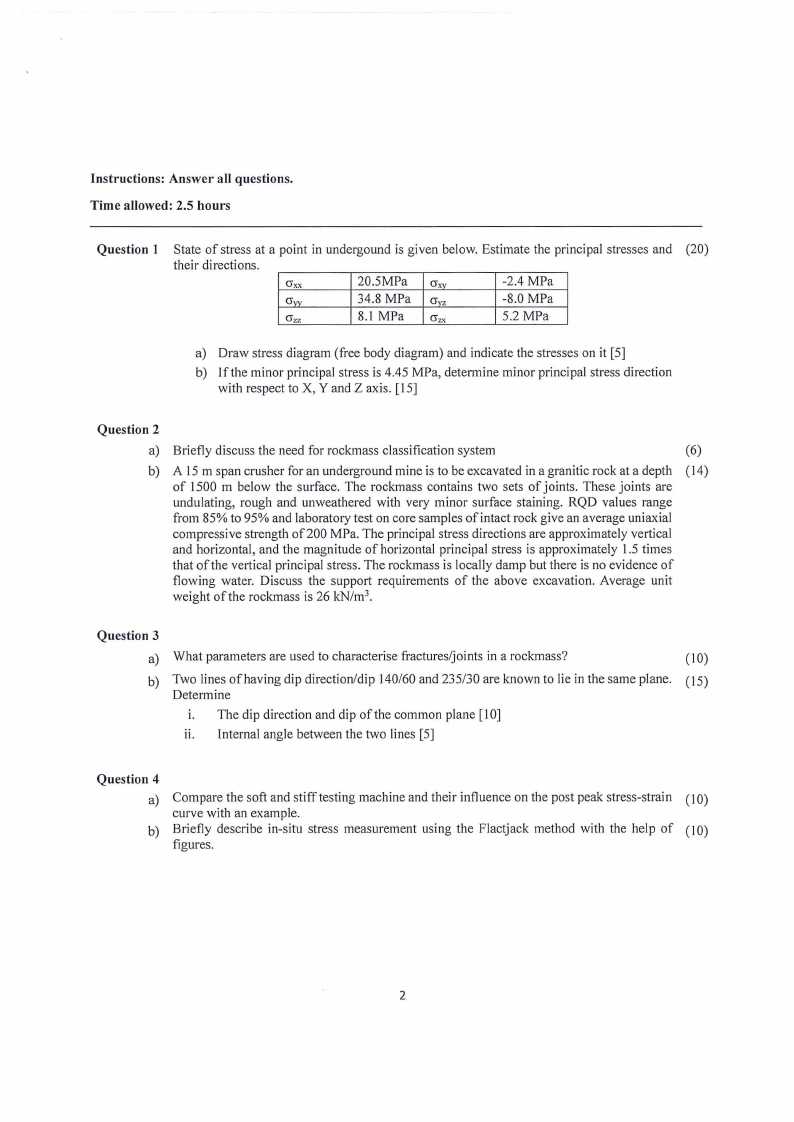

Table I. Description and ratings for the input parameters of the Q-system (simplified from Grimstad and Barton, 1993).

RQD (Rock Qualitv Desianation)

Very poor

Poor

Fair

Good

Excellent

Notes:

RQD = 0- 25%

25 -50

50- 75

75 - 90

90 - 100

(i) Where ROD is reported or measured as < 1O (including OJ,

a nominal value of 1O is used to evaluate Q

(ii) ROD intervals of 5, i.e. 100, 95, 90, etc.

are sufficiently accurate

Jn (ioint set number)

Massive, no or few joints

Jn = 0.5 - 1

One joint set

2

One joint set plus random joints

3

Two joint sets

4

Two ioint sets plus random joints

6

Three joint sets

9

Three joint sets plus random joints

12

Four or more joint sets, heavily jointed, "sugar-cube", etc.

15

Crushed rock, earthlike

20

Notes: (i) For tunnel intersections. use (3.0 x Jn): (ii) For portals. use (2.0 x Jn)

r 10,n roup hness num b er)

a) Rock-wall contact,

bl rock-wall contact before 10 cm shear

Discontinuous joints

Jr= 4

Rough or irregular, undulating

3

Smooth, undulating

2

Slickensided, undulating

1.5

Rough or irregular, planar

1.5

Smooth, planar

1.0

Slickensided, Planar

0.5

Note: i) Descriptions refer to small scale features,

and intermediate scale features. in that order

cl No rock-wall contact when sheared

Zone containing clay minerals thick enough to prevent rock-

wall contact

Sandy, gravelly or crushed zone thick enough to prevent rock

wall contact

Notes:

i) Add 1.0 if the mean spacing of the relevant joint set is greater than 3 m

ii) Jr= 0. 5 can be used for planar, s/ickensided joints having lineations,

provided the lineations are oriented for minimum strength

Jr= 1.0

1.0

J a C1'0tl,nt a era f10n num ber)

Ca,:

1 gi

2

UC·o

C: -~

u0

JOINT WALL CHARACTER

Condition

Healed or welded joints: filling of quartz, epidote, etc.

CLEAN JOINTS Fresh joint walls:

no coating or filling, except from staining (rust)

Slightly altered joint walls: non-softening mineral coatings, clay-free particles, etc.

COATING OR THIN Friction materials:

FILLING

Cohesive materials:

sand, silt, calcite, etc. (non-softening)

clav. chlorite talc etc. /softenino)

1

c 0

C:

tr5o

()

a,

E

0u

e0 n

FILLING OF:

Friction materials

Hard cohesive materials

Soft cohesive materials

Swelling clay materials

Some wa/J contact

Type

Thin filling(< 5 mm)

sand, silt calcite, etc. (non-softening)

Ja = 4

compacted filling of clay, chlorite, talc, etc.

6

medium to low overconsolidated clay, chlorite, talc,

8

filling material exhibits swelling properties

8 - 12

Wa/J contact

Ja = 0.75

1

2

3

4

No wa/J contact

Thick filling

Ja = a

5 - 10

12

13 - 20

J w C1om. t wa er re dUCf/On f.actor

Dry excavations or minor inflow, i.e. < 5 I/min locally

Medium inflow or pressure, occasional outwash of joint fillings

Large inflow or high pressure in competent rock with unfilled joints

Large inflow or high pressure, considerable outwash of joint fillings

Exceptionally high inflow or water pressure at blasting, decaying with time

Exceptionally high inflow or water pressure continuing without noticeable decay

Note: (i) The last four factors are crude estimales. Increase Jw if drainage measures are installed

(ii) Special problems caused by ice formation are not considered

Pw< 1 kg/cm'

1 - 2.5

2.5 - 10

2.5 - 10

> 10

> 10

Jw= 1

0.66

0.5

0.3

0.2 - 0.1

0.1 - 0.05

SRF (Stress Reduction Factor)

Multiple weakness zones with clay or chemically disintegrated rock, very loose surrounding rock (any depth)

Single weakness zones containing clay or chemically disintegrated rock (depth of excavation < 50 m)

Single weakness zones containing clay or chemically disintegrated rock (depth of excavation > 50 m)

Multiple shear zones in competent rock (clay-free), loose surrounding rock (any depth)

Single shear zones in competent rock (clay-free), loose surrounding rock (depth of excavation < 50 m)

Single shear zones in competent rock (clay-free), loose surrounding rock (depth of excavation > 50 m)

Loose, open ioints, heavilv iointed or "suoar-cube", etc. (anv depth)

SRF = 10

5

2.5

7.5

5

2.5

5

Note:

(i) Reduce these SRF values by 25 - 50% if the relevant shear zones only influence, but do not intersect the e~xc_a_v_a~tio_n_·~-----~---

ac I cr1 a 0 I ac

SRF

Low stress, near surface, open joints

> 200 < 0.01

2.5

Medium stress, favourable stress condition

200 - 10 0.01 - 0.3

1

High stress, very tight structure. Usually favourable to stability, may be except for walls

10 - 5 0,3 - 0.4

0.5 - 2

Moderate slabbing after > 1 hour in massive rock

5-3 0.5 - 0.65 5 - 50

Slabbing and rock burst after a few minutes in massive rock

3-2

0.65 - 1 50 - 200

Heavy rock burst (strain burst) and immediate dynamic deformation in massive rock

<2

>1

200 - 400

Notes: (ii)Forstronglyanisotropicstressfield(ifmeasured):when5<

a 1 /u, <10, reduce uc to0.75 uc. When a1/u3> 10, reduce uc to0.5uc

(iii) Few case records available where depth of crown below surface is less than span width. Suggest SRF increase from 2.5 to 5 for low stress cases

ao I ac

SRF

Squeezing

rock

Swelling

rock

Plastic flow of incompetent rock under

the influence of high pressure

Chemical swelling activity depending on

presence of water

Mild squeezing rock pressure

Heavy soueezino rock pressure

Mild swelling rock pressure

Heavy swelling rock pressure

1-5

>5

5- 10

10 - 20

5 - 10

10 - 15

|

6 Page 6 |

▲back to top |

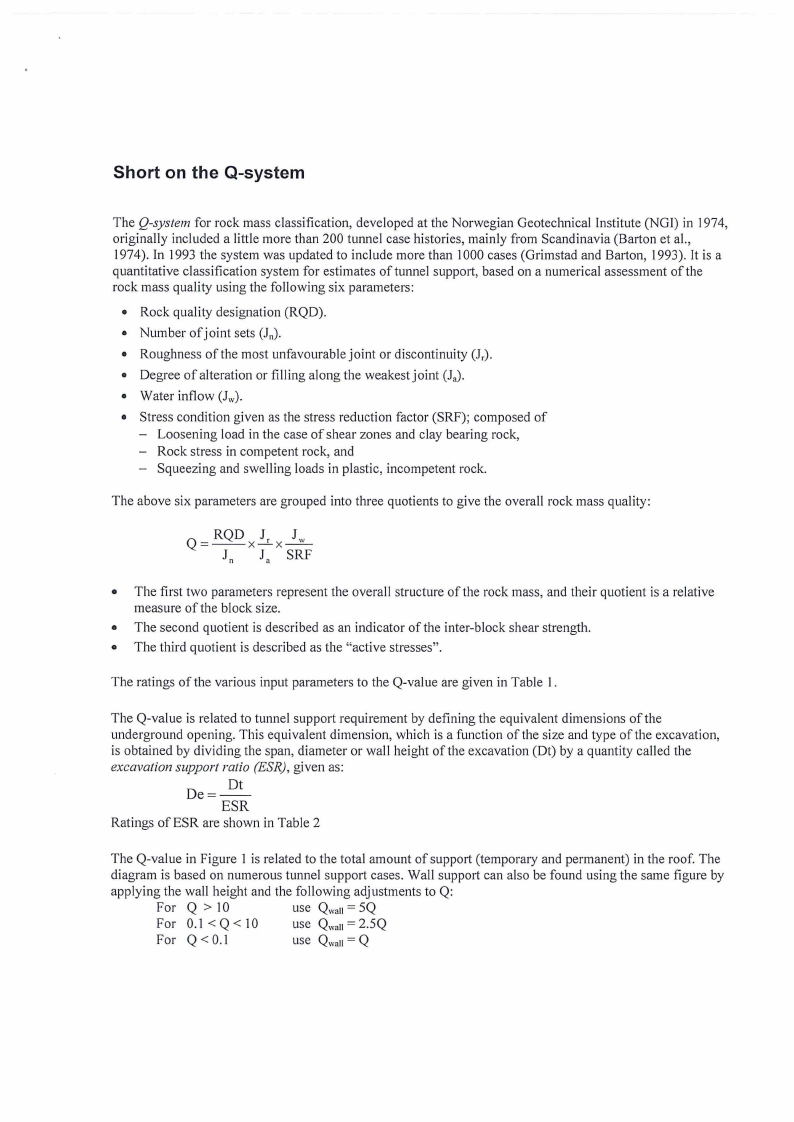

Table 2 Ratings of the excavation support ratio (ESR) (from Barton et. al., 1974).

Type or use of underground opening

Temporary mine openings

Vertical shafts, rectangular and circular respectively

Water tunnels, permanent mine openings, adits, drifts

Storage caverns, road tunnels with little traffic, access tunnels, etc.

Power stations, road and railway tunnels with heavy traffic, civil defence shelters, etc.

Nuclear power plants, railroad stations, sport arenas, etc.

ESR

3.5

2.0 - 2.5

1.6

1.3

1.0

0.8

G

Exceptionally

poor

ROCK MASS QUALITY AND ROCK SUPPORT

F

Extremely

poor

E

Very

poor

D

C

B

Poor Fair Good

20

Very

good

A

Ext.

good

Exe.

good

0.001

0.004 0.01

0.04 0.1 j

0.4 1

j4

10

140 100

400- Q-v:iuo for

~;lr~~~~"o'rt I I I I

I I I I I I II

I

I I I III

I I I , I I -, roo support

O_ll"_.00..6. -'-'--'--Q+.1-~0'-.2-'--,-;0+.-'4--'0.7~1+----'z'----'--4--'-5'-'-s""'1-+Q-~2,',0-'--4~0 -'-'-'70-'·-l1QQ

Q-value

Support categories

RRS - spacing related to Q-value

G:>Unsupported or spot bolting

@ Spot bolling (SB)

@ Systematic bolting,fibrecrete 5-6cm thick

© Bolting and fibrecrete 6-9cm thick (E500)

(i, Bolting and fibrecrete 9-12cm thick (E700)

(j) Bolting and fibrecrete 12-15cm + reinforced ribs of shotcrete (RRS I)

(i> Bolting and fibrecrete (E1000) > 15cm thick+ reiforced ribs of shotcrete (RRS II)

C1i-Bolting+ cast concrete lining (CCA) or fibrecrete (E1000)

® Special evaluations

tc:1 Si30/6 016-20 (span 10m)

11 040/6 + 2 016-20 (span 20m)

Si35/6 016-20 (span 5m)

(r11-)045/6 + 2 016-20 (span 10m)

055/6 + 4 020 (span 20m)

(11/ 11\\

040/6 + 4 016-20 (span Sm)

055/6 + 4 020 (soan 10m\\

Si30/6 = single layer of 6 rebars,

30cm thickness of sholcrete

Bolt spacing is mainly based on bolt diam. 0200mm

Sholcrele = sprayed concrete (S)

Fibrecrete = fibre reinforced sprayed concrete (Sfr)

RRS = reinforced rib of shotcrele

clc = RRS spacing centre - centre

0 = double layer of rebars

016 = rebar diameter (16mm)

E = energy adsorbtion on fibre reinforced shotcrete

ESR = excavation support ratio

Figure I The Q system chart for rock support estimate, developed by the Norwegian Geotechnical Institute (NGI),

(based on www.ngi.no, 2014). The Qwall values have been introduced in the chart

|

7 Page 7 |

▲back to top |

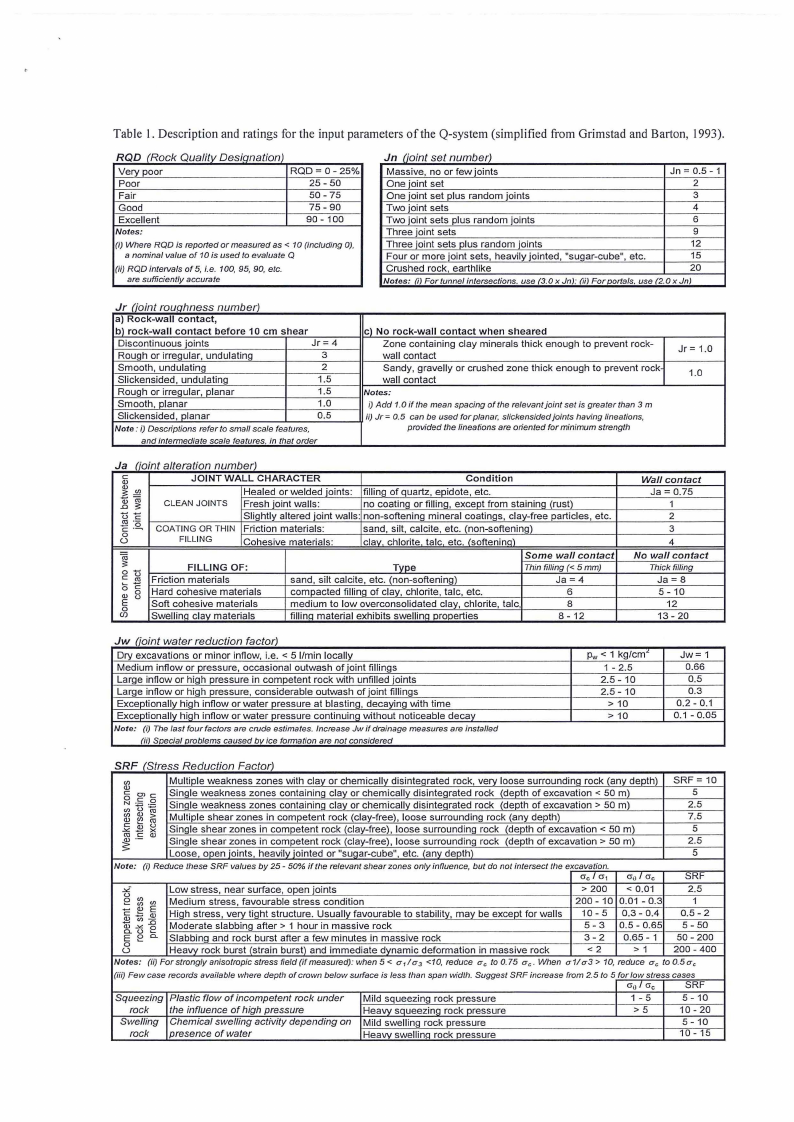

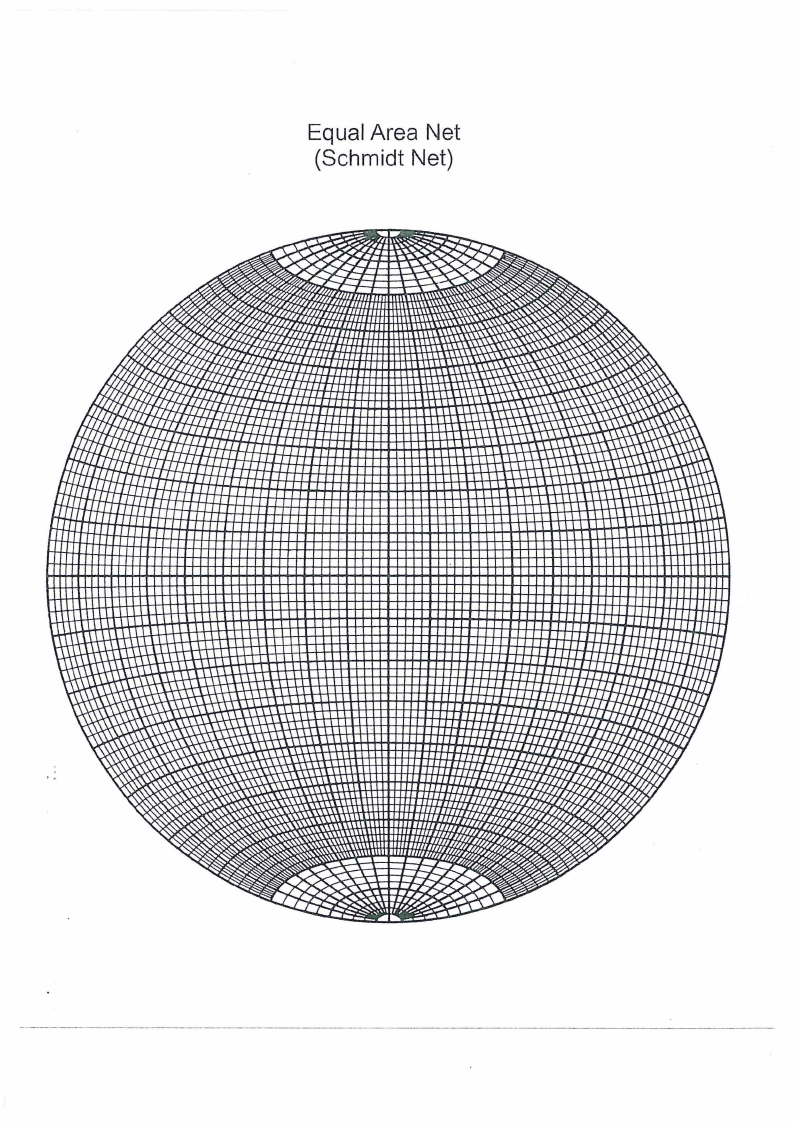

Equal Area Net

(Schmidt Net)