|

PDF711S - Phase Diagram and Formatting Processes 314 - 1st Opp - June 2022 |

|

1 Page 1 |

▲back to top |

n Am I BI A u n IVER s ITY

OF SCIEnCE Ano TECHnOLOGY

FACULTYOF ENGINEERINGAND SPATIALSCIENCES

DEPARTMENT OF MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 08BMET

LEVEL: 7

COURSE CODE: PDF711S

COURSE NAME: PHASE DIAGRAMS AND FORMING

PROCESSES314

SESSION: JUNE 2022

DURATION: 2 HOURS

PAPER: THEORY

MARKS: 65

EXAMINER(S)

FIRSTOPPORTUNITYQUESTION PAPER

Mrs. Jaquiline Tatenda Kurasha

MODERATOR:

Professor Sofya Mitropolskaya

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examinationpaper.

2. Non-programmablecalculator.

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

1

|

2 Page 2 |

▲back to top |

|

3 Page 3 |

▲back to top |

Question 1 {15 Marks)

(a) What is the significance of the atomic packing factor?

[1]

(b) Linear density in a given crystallographic direction represents a fraction of the line length that

is occupied by atoms. At room temperature, the crystal structures of iron and aluminium are

BCCand FCCrespectively.

(i)

Calculate the linear density for [110] and (111] directions in iron and aluminium

respectively.

[4]

(ii)

Comment on your answers in (i), and explain why aluminium is softer and more ductile

than iron based on your answers in (i).

[2]

(c) Both XRD analysis and elemental analysis in the SEM generate peaks and troughs in the

spectrum. What is the fundamental difference between the EDS spectrum and the x-ray

diffraction spectrum?

[1]

(d) The {100} planes of a body-centred cubic crystal have a separation of 0.1181 nm. If these

planes are irradiated with x-rays from a copper target, the strongest line has a wavelength of

0.1541 nm.

(i)

At what angle will first order reflection occur?

[2]

(ii)

At what angle will second order reflection occur? What conclusion can you make?

[3]

(iii) Calculate the lattice parameter of the crystal.

[2]

Question 2 (20 marks)

(a) Distinguish between an intrinsic and extrinsic staking fault.

[2]

(b) The activation enthalpy for the formation of vacancies in gold is 91 500 J/mol. Calculate the

equilibrium concentration of vacancies in gold at 727 °C.

[2]

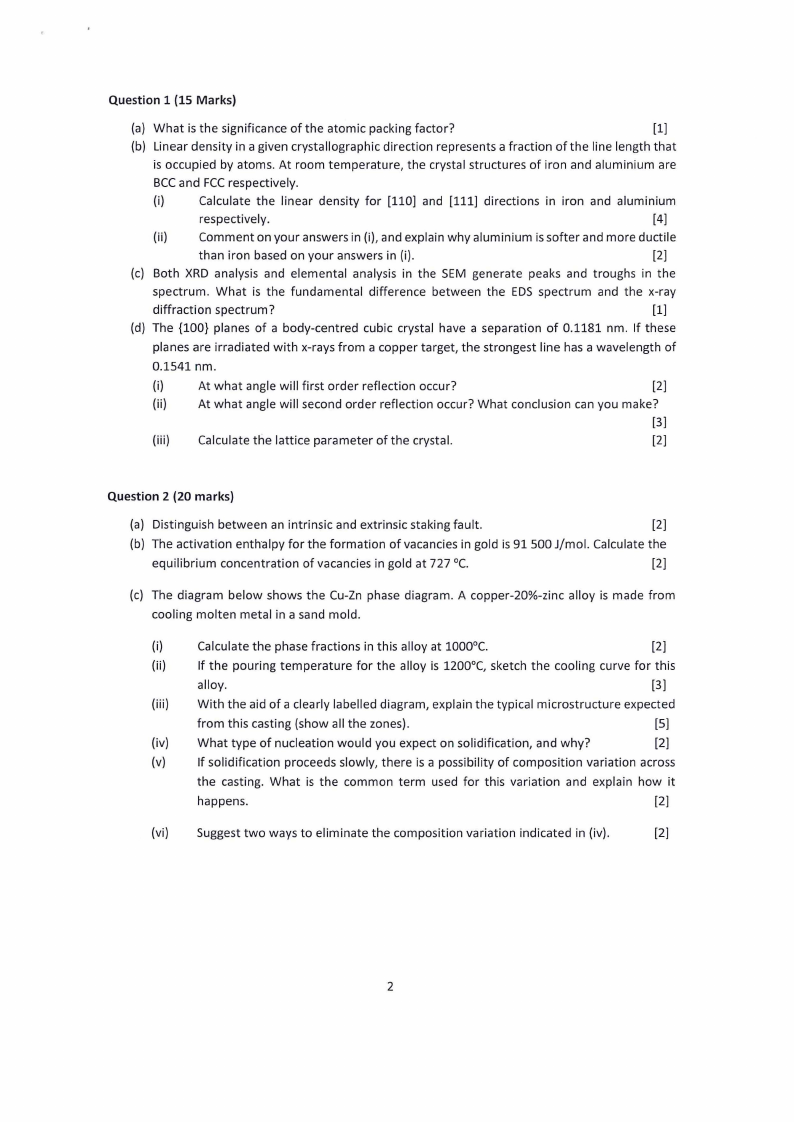

(c) The diagram below shows the Cu-Zn phase diagram. A copper-20%-zinc alloy is made from

cooling molten metal in a sand mold.

(i)

Calculate the phase fractions in this alloy at 1000°C.

[2]

(ii)

If the pouring temperature for the alloy is 1200°C, sketch the cooling curve for this

alloy.

[3]

(iii) With the aid of a clearly labelled diagram, explain the typical microstructure expected

from this casting (show all the zones).

(5]

(iv) What type of nucleation would you expect on solidification, and why?

[2]

(v)

If solidification proceeds slowly, there is a possibility of composition variation across

the casting. What is the common term used for this variation and explain how it

happens.

[2]

(vi) Suggest two ways to eliminate the composition variation indicated in (iv).

[2]

2

|

4 Page 4 |

▲back to top |

!ODO -

01)0

- 2000

- l800

!GOO

"=

-- LUU!

Question 3 (15 Marks)

(a) Metal forming processes can be broadly classified based on working temperature.

(i)

Give and briefly describe the three classes of metal working temperatures.

(ii)

Explain the effect of these working temperatures on the microstructure

components made.

(b) In most metal working processes, friction is unavoidable.

[3]

of the

[3]

(i) Give the two types of friction often experienced in metal forming and distinguish between

them.

[2]

(ii) Give two reasons why friction is generally undesirable in metal forming operations. [2]

(c) You are supposed to select a material to make a propeller shaft for a fishing boat to sail on

the Namibian ocean waters. Both annealed naval brass and annealed low carbon steel have a

strain hardening exponent of 0.21. However, naval brass has a strength coefficient of 585MPa,

and the strength coefficient of annealed low carbon steel is 600 MPa, and the maximum strain

after deforming the materials is 0.01.

(i)

Why are the annealed materials considered?

[1]

(ii)

Determine the respective flow stresses of the materials.

(3]

(iii) Which material is more suitable for the application, and why?

[1]

3

|

5 Page 5 |

▲back to top |

Question 4 (15 marks)

(a) In metallurgical joining operations, there is generally the need to shield/protect

area from the atmosphere during joining.

(i)

Give the three main types of metallurgical joining operations.

(ii)

Explain why shielding is required.

(iii) Give the two basic methods of shielding often used.

the joint

[3]

[1]

[2]

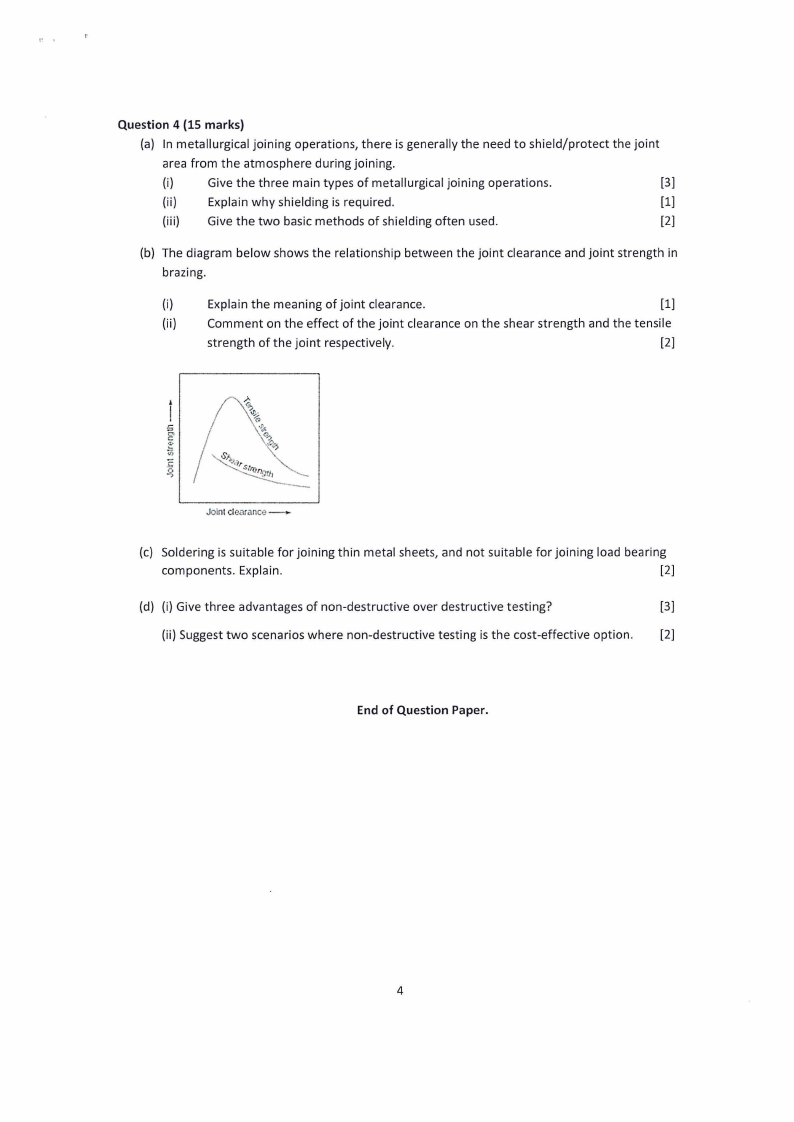

(b) The diagram below shows the relationship between the joint clearance and joint strength in

brazing.

(i)

Explain the meaning of joint clearance.

[1]

(ii)

Comment on the effect of the joint clearance on the shear strength and the tensile

strength of the joint respectively.

[2]

,>.

"'~-

v~

'½

~0

&.

I

Joint clear,,nce-

(c) Soldering is suitable for joining thin metal sheets, and not suitable for joining load bearing

components. Explain.

[2]

(d) (i) Give three advantages of non-destructive over destructive testing?

[3]

(ii) Suggest two scenarios where non-destructive testing is the cost-effective option.

[2]

End of Question Paper.

4

|

6 Page 6 |

▲back to top |