|

SUM710S - Surface Mining 315 - 1st Opp - June 2022 |

|

1 Page 1 |

▲back to top |

nAm I BI A u n IVE RS ITY

OF SCIEn CE Ano TECHn OLOGY

FACULTYOF ENGINEERINGAND SPATIALSCIENCES

DEPARTMENT OF MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN MINING ENGINEERING

QUALIFICATION CODE: 0SBMIN

LEVEL: 8

COURSE CODE: SUM710S

COURSE NAME: SURFACE MINING 315

SESSION: JUNE 2022

DURATION: 2 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

FIRSTOPPORTUNITY QUESTION PAPER

Mr. Privilege Shava

MODERATOR:

Dr. Mallikarjun Pillalamarry

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examination paper.

2. Scientific Calculator

THIS QUESTION PAPER CONSISTS OF 4 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

|

3 Page 3 |

▲back to top |

Question 1

a) With reference to open-pit mining, explain how the following factors would govern

bench height:

i. Degree of selectivity required in separating ore and waste.

[5]

ii. Production rate.

[5]

iii. Physical characteristics of the deposit.

[5]

b) It is often necessary to consider the conversion of a surface mining operation to an

underground mining operation. Evaluate the factors that you would consider in

converting a surface mining operation to an underground mining operation.

[10]

Question 2

a) The following surface mine production scenario is given:

Production Required ................2000 t/hour

Material ..................................... Blasted in 6m high face; pile;

Density .......................................! 600 kg/m 3

In addition to the above information, you are also given that the Front-End-Loader

(FEL) is being deployed in LHD mode (Load-Haul-Dump) doing loading on a hard level

surface for loader maneuvering with a total basic cycle time of 1.0 min. FELmaximum

activity per hour is 50.0 min.

I. Determine a suitable FELfor this application.

[5]

11. Calculate the tonnage generated per cycle.

[2]

Ill. What additional considerations would you make in your selection process? [4]

b) Distinguish between Discontinuous/Cyclical and Cyclical equipment as applied to a

surface mining operation, giving at least two examples of each class of equipment. [4]

c) Distinguish between Design Capacity and Technical Capacity of mining equipment,

clearly outlining the parameters that define each of the two capacities.

[4]

d) Explain the term Ultimate Pit Limit (UPL).

[2]

e) How do the following impact on d)

I. Stripping Ratio

[2]

11. Overall Slope Angle

[2]

Question 3

You are presented with the following surface mine stripping operation:

Material parameters:

Volume to be excavated, hauled and compacted -

45 000m 3

1

|

4 Page 4 |

▲back to top |

• Compaction factor -

0.93

• Bank density -

2 150 kg/m 3

• Loose density -

1500 kg/m 3

Hydraulic excavator (1 unit available):

• Bucket size -

8.2 m3

• Bucket fill factor -

0.96

• First bucket -

0.1 mins

• Additional bucket -

0.7 mins

• Truck transfer time -

0.5 mins

• Maximum loader activity/h -

52 mins

• Charge per hour -

$185/h

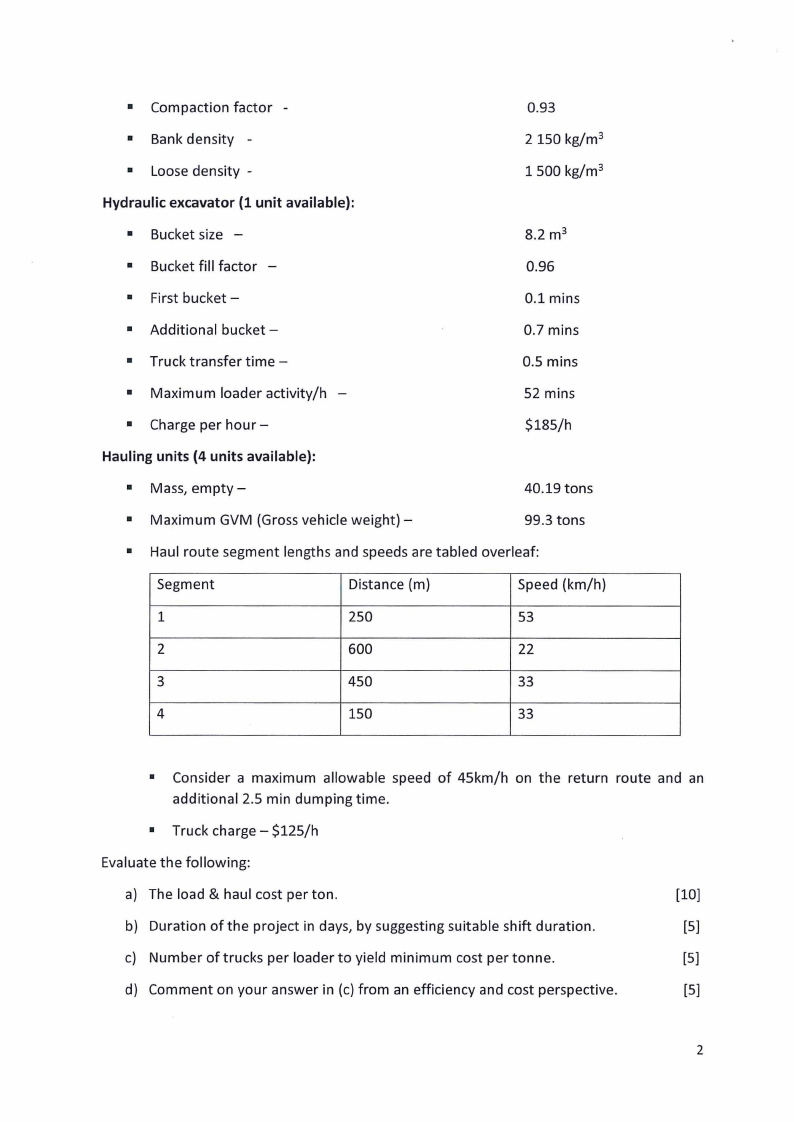

Hauling units (4 units available):

• Mass, empty -

40.19 tons

• Maximum GVM (Gross vehicle weight)-

99.3 tons

• Haul route segment lengths and speeds are tabled overleaf:

Segment

Distance (m)

Speed (km/h)

1

250

53

2

600

22

3

450

33

4

150

33

• Consider a maximum allowable speed of 45km/h on the return route and an

additional 2.5 min dumping time.

• Truck charge - $125/h

Evaluate the following:

a) The load & haul cost per ton.

[10]

b) Duration of the project in days, by suggesting suitable shift duration.

[5]

c) Number of trucks per loader to yield minimum cost per tonne.

[5]

d) Comment on your answer in (c) from an efficiency and cost perspective.

[5]

2

|

5 Page 5 |

▲back to top |

Make use of the cr1eue~s provided for this question.

Question 4

a} An open-pit mine is experiencing persistent "fall-of-ground" at one section of the pit.

In your opinion, what could be the key potential causes (two} of this situation?

[4]

b} Explain how the situation in a} can be remedied, and any potential impacts of the

proposed remedies.

[6]

c} Haul roads are an important part of the design of an open-pit mine.

Identify any three factors that need consideration in the location of a haul road. [3]

d} Distinguish the possible haul road configuration types. You may use a diagram to aid

your explanation.

[6]

e} What are the comparative advantages and disadvantages of each of the haul road

configurations identified above?

[6]

--End of Question Paper--

3

|

6 Page 6 |

▲back to top |