|

CEN810S - Corrosion Engineering 414 - 2nd OPP - JUN 2023 |

|

1 Page 1 |

▲back to top |

n Am I B I A u n IVER s I TY

OF SCIEnCE Ano TECHnOLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CIVIL, MINING AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN METALLURGY

QUALIFICATION CODE: 08BMET

LEVEL: 8

COURSECODE: CEN810S

COURSE NAME: Corrosion Engineering 414

SESSION:June 2023

DURATION: 2 HOURS

PAPER:2

MARKS: 70

EXAMINER($)

SECOND OPPORTUNITY PAPER

Prof D Groot

MODERATOR:

Prof J van der Merwe, University of the Witwatersrand

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

2. Scientific calculator, non-programmable

THIS PAPER CONSISTS OF 4 PAGES (including this front page)

|

2 Page 2 |

▲back to top |

Question 1

Passivation plays an important role in corrosion of metals and alloys.

(a) Describe the behaviour of an "active-passive" metal when a fresh surface is exposed to a corrosive

environment. Draw a schematic Evans diagram to illustrate your discussion, labelling the various regions

on the diagram. Indicate important potentials and current densities.

[10]

(b) Give an example of such a metal or alloy.

[1]

Question 2

The formation of mill scale during certain processing of e.g. steel profiles is considered a form of

corrosion.

(a) Compare this type of corrosion to the other broad class of corrosion mechanisms, and discuss

how this type may be modeled.

[7]

(b) Discuss the effect of metal oxide volume on the protective ability of an oxide layer on a metal.

[8]

Question 3

lntergranular corrosion {IGC) is a localised corrosion that occurs at or near the grain boundaries in a metal or

alloy.

(a) State at least three general factors that can cause this type of corrosion.

[3]

(b) State what the main preventative measures against IGC are that you can take during the metal alloying

stage.

[2]

Question 4

Consider an unpainted mild steel item exposed to the atmosphere. After some time, examination of the

piece shows general corrosion. Hint: keep in mind the practical experiment you did.

Explain, in terms of the basic aqueous corrosion cell, how this type of corrosion has occurred.

[9]

Question 5

A brass (copper-based alloy) fitting used in a marine application is joined by soldering with lead-tin solder. This

application is used even in fresh water plumbing systems.

(a) Do you expect corrosion to occur? Explain your answer.

[3]

{b) Explain the advantages and disadvantages of this type of joining.

[2]

Question 6

Cathodic protection may be achieved by the use of an impressed current from an electrical source, or by the

use of sacrificial anodes. Discuss the merits and demerits of sacrificial anodes approach.

[6)

Question 7

Consider a pipeline made of high strength steel, carrying a flow of seawater to a desalination plant. One part

is encased in concrete, running into the sea. The rest is buried in moist soil, running to the plant. At the plant

it is connected via bolted flanges to an electrical pump. The pump housing is a casting in naval brass.

(a) Is stress corrosion cracking likely, in your opinion? Explain your answer.

[3]

(b) What (other) type(s) of corrosion may be expected in this situation? What could be done to manage the

problem(s)?

[9]

2

|

3 Page 3 |

▲back to top |

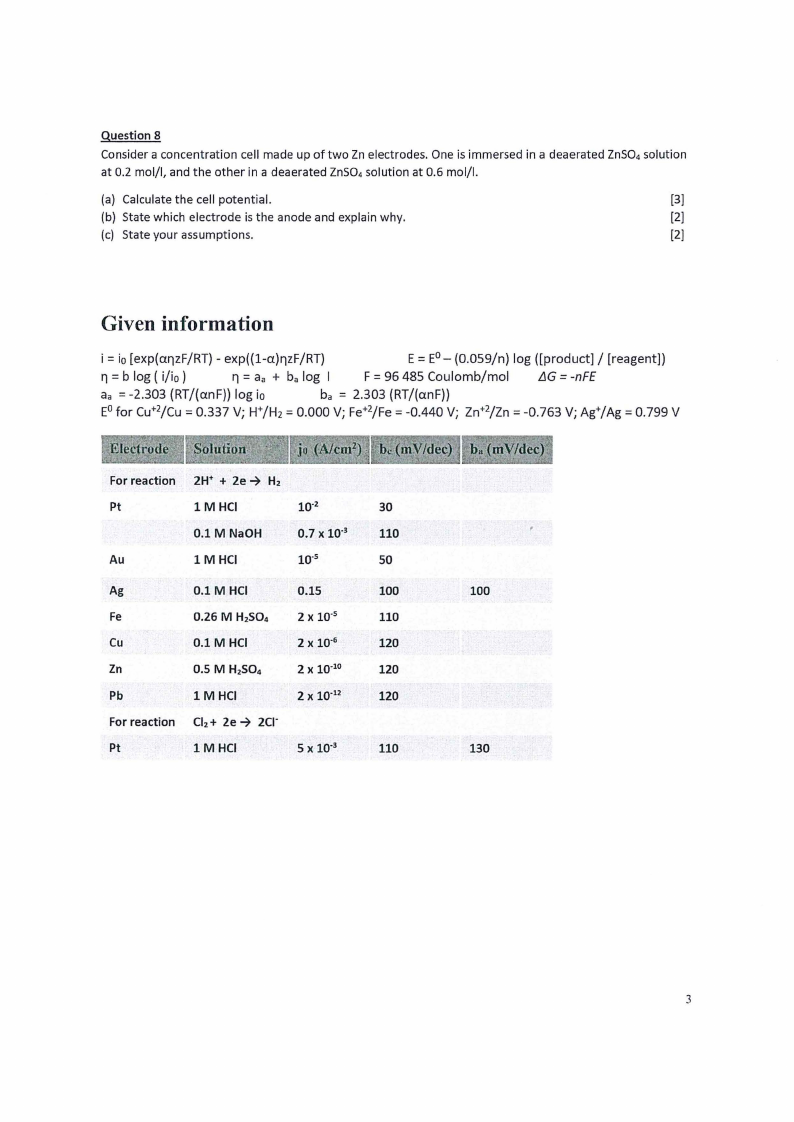

Question 8

Consider a concentration cell made up of two Zn electrodes. One is immersed in a deaerated ZnS04 solution

at 0.2 mol/1, and the other in a deaerated ZnS04 solution at 0.6 mol/1.

(a) Calculate the cell potential.

[3]

(b) State which electrode is the anode and explain why.

[2]

(c) State your assumptions.

[2]

Given information

i = io[exp(ar,zF/RT) - exp((l-a)r,zF/RT)

E = E0 - (0.059/n) log ([product]/ [reagent])

ri =b log ( i/io)

ri =aa + ba log I

F =96 485 Coulomb/mo!

LlG = -nFE

= aa -2.303 (RT/(anF)) log io

= ba 2.303 (RT/(anF))

= = = = E0 for cu+2/Cu 0.337 V; W/H 2 0.000 V; Fe+2/Fe -0.440 V; zn+2/Zn -0.763 V; Ag+/Ag = 0.799 V

For reaction 2W +

Hz

Pt

lM HCI

10-2

30

0.1 M NaOH

0.7 X 10'3

110

Au

1 M HCI

10·5

50

Ag

0.1 M HCI

0.15

100

100

Fe

0.26 M H2S04 2 X 10·5

110

Cu

0.1 M HCI

2xl0· 6

120

Zn

0.5 M H2S04

2 X 10"10

120

Pb

1 MHCI

2 X 10"12

120

For reaction Clz+ 2e 2c1·

Pt

lMHCI

5 X 10"3

110

130

3

|

4 Page 4 |

▲back to top |

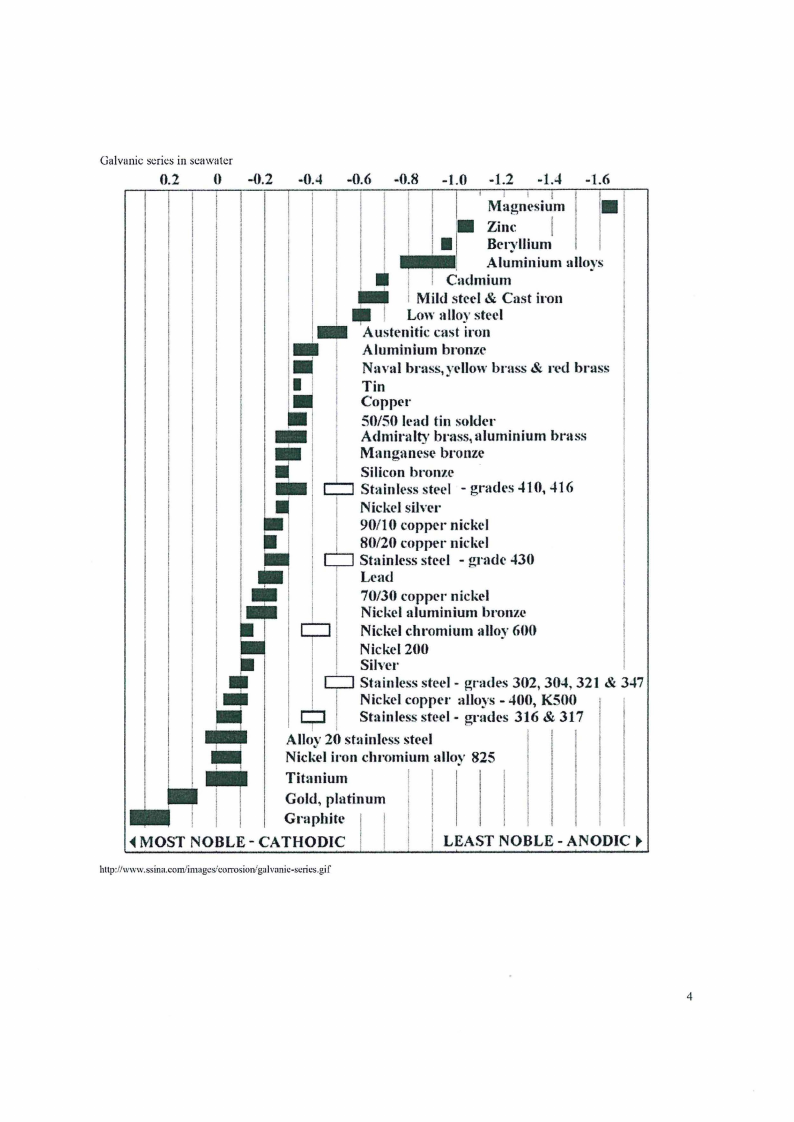

Galvanic series in seawater

0.2 0 -0.2 -0.4 -0.6 -0.8 -1.0 -1.2 -1.4 -1.6

III

Magn('sium

I Zinc

BcQ'llium

.. I Aluminium ullovs

I Cadmium

·

l Mild steel & Cast iron

- I Low ulloysteel

Austenitic rnst iron

Aluminium bronze

Narnl brass,yl'llow brass & l'<'d brass

Tin

Copp'-'r

50/50 lead tin sold<•r

Admiralty brass, nlurniniurn bmss

Manganese bronze

Silicon bronze

Stainless st('el - grades -H0, -tl 6

Nickel sih·er

90/10 coppt'r nickel

80/20 copper nickel

Stainless steel - gradr -430

Lead

70/30 copper nickel

Nickel aluminium bronze

Nickel <:hromium alloy 600

Nickel 200

Silver

Stainless steel - grades 302, 304, 321 & 3-47

Nickel copper allo)S - 400, K500

9

Stainless steel• grades 316 & 317

Alloy 20 sb1inlcss st<'el

Nickel iron chromium alloy 825

Titanium

j

I I Gold, platinum

Gr;1phitc

MOST NOBLE- CATHODIC

'I

!I

LEAST NOBLE - ANODIC

http://ww\\v.ssina.com/i1nagcsicorrosion!ga)vanic-scrics.gif

4