|

UDM711S - Underground Mining 315 - 2nd OPP - June 2023 |

|

1 Page 1 |

▲back to top |

nAm I BIA untVERSITY

OF SCIEnCE

TECHnOLOGY

FACULTY OF ENGINEERIND AND BUILT THE ENVIRONMENT

DEPARTMENT OF CIVIL, MINING, AND PROCESSENGINEERING

QUALIFICATION: BACHELOR OF ENGINEERING IN MINING ENGINEERING

QUALIFICATION CODE: 08BMIN-SS

LEVEL: 5

COURSE CODE: UDM711S

COURSE NAME: UNDERGROUND MINING 315

SESSION:JUNE 2023

DURATION: 2 HOURS

PAPER: THEORY AND CALCULATIONS

MARKS:100

EXAMINER

SECOND OPPORTUNITY QUESTION PAPER

Mr. Tshivute lipinge

MODERATOR:

Mr. Ruben Mwalwange

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each question are indicated at the end of each question.

4. Please ensure that your writing is legible, neat, and presentable.

PERMISSIBLE MATERIALS

1. Examination paper.

THIS QUESTION PAPERCONSISTSOF 4 PAGES (Including this front page)

I

|

2 Page 2 |

▲back to top |

Question 1

a) Outline five different variants of cut and fill stoping. (5 marks)

b) Outline three variants of block caving and two ore drawing methods used in block caving.

(Smarks)

c) Compare the underhand, and overhand stoping methods. {10 marks)

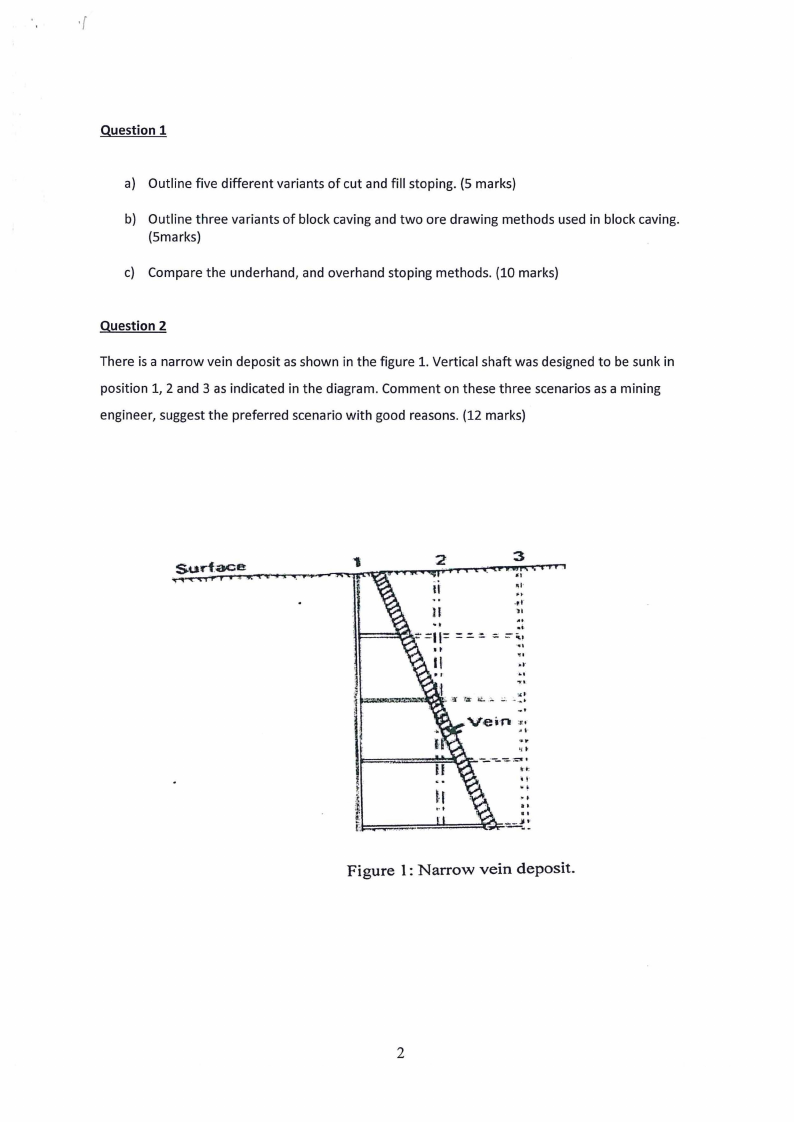

Question 2

There is a narrow vein deposit as shown in the figure 1. Vertical shaft was designed to be sunk in

position 1, 2 and 3 as indicated in the diagram. Comment on these three scenarios as a mining

engineer, suggest the preferred scenario with good reasons. (12 marks)

Surf.ace

3

.,.

...,,

)I

••

..,..

l:

.....

(

I

.,

.,,,.

!

A;

f..

•!

..• I''

--- ~-.II•

Figure I: Narrow vein deposit.

2

|

3 Page 3 |

▲back to top |

.' [

Question 3

As a mining engineer responsible for planning underground mining main level layout, what are those

layout requirements should you consider in your planning process? (10 marks).

Question 4

During the production meeting, the plant manager complain that the ore delivered to the processing

plant might contain a lot of dilution and plant recover grade is to low and does not meet the customer

specification. As a Mining Engineer, your Mine Manager has given you a task to look into this matter

seriously. The waste tonnes drawn is 600 tonnes, the tonnes blasted in the stope is 3500 tonnes,and

the tonnes drawn from the draw

Points is 1500 tonnes. Calculate the TD ore and waste tonnes drawn, the recovery R, the dilution

factor D, the extraction rate EX,and the yield for recovery and extraction. (12 marks)

Question 5.

A mine has a zinc deposit that is being mined with a target of 30 000 tonnes of ore per month, with

an open stope mining method. The stope is on average 20m wide and inter-level spacing of 50m.

Longitudinal mining is being executed with the length of the stope being around 200m long. Rings are

planned with a burden of 1.6m and spacing 2.lm. If blasting is done once every week to meet

production and specific gravity of 2.5 can be applied.

a) Draw the section of the mining method. (4)

b) Compute the stope volume (2)

c) Compute stope tonnage, and ring tonnage (3 marks)

d) Compute the number of rings that must be blasted every week. (3)

e) How long does the stope last before it is mined out?

(3)

Question 6

State and discuss ten factors that you will consider when selecting a mining method. (10 marks)

Question 7.

a) Discussthe stope preparation and mining of a shrinkage stoping mining method. (10 marks)

b) What are the advantages of shrinkage stoping mining method? (5 marks)

3

|

4 Page 4 |

▲back to top |

Question 9.

Name any six design factors (two from each of the main areas namely geometrical, material flow, and

operational) which are critical in sublevel caving (6 marks)

End of Test paper.

4