|

ORC711S - Operations Research 313 - 1st Opp - June 2022 |

|

1 Page 1 |

▲back to top |

nAmlBIA unlVERSITY

OF SCIEnCE Ano TECHnOLOGY

FACULTYOF ENGINEERINGAND SPATIALSCIENCE

DEPARTMENTOF Mining and Process Engineering

QUALIFICATION : Bachelors of Engineering in Mining Engineering

QUALIFICATION CODE: BEMIN

LEVEL: 8

COURSE CODE: OPC 711S

COURSENAME: OPERATIONSRESEARCH

SESSION: JUNE 2022

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

MODERATOR:

FIRSTOPPORTUNITYQUESTION PAPER

Lawrence Madziwa

Dr Mallikarjun Rao Pillalamarry

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each questions are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 5 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

1. All loaded mine trucks traveling from the mine pit to the plant are required to stop at a

weigh and scan station. Trucks arrive at the station at a rate of200 per 8-hour shift, and the

station can weigh, on the average, 220 trucks per shift.

a. Determine the following

I. the average number of trucks waiting

[3]

II. the average time spent waiting and being weighed at the station by each

truck, and

[5]

III. the average waiting time before being weighed for each truck. [5]

b. Truck drivers find out they are queueing at the station longer than 15 minutes

as planned, on average, they will start driving slower thus reducing mine

productivity. The mine estimates that it loses $10,000 in downtime per year for

each extra minute the trucks must wait at the station. A new set of scales would

have the same service capacity as the present set of scales, and it is assumed that

arriving trucks would line up equally behind the two sets of scales. It would cost

$50,000 per year to operate the new scales. Should the mine install the new set

of scales?

[8]

2. You are responsible for transporting five items on a limited space of 13 tons from

Windhoek to Swakopmund. There are five different items that your company can

transport between Windhoek and Swakopmund. Each item has a weight in tons, a net

profit in thousands of dollars, and an unlimited number of items that are available for

shipping as shown in Table below. Use dynamic programming to determine how

many of each item should be shipped to maximize profits.

[20]

Item

Weight

1

7

2

5

3

4

4

3

5

1

Profit I Unit ($)

9

4

3

2

1/2

Number Available

unlimited

unlimited

unlimited

unlimited

unlimited

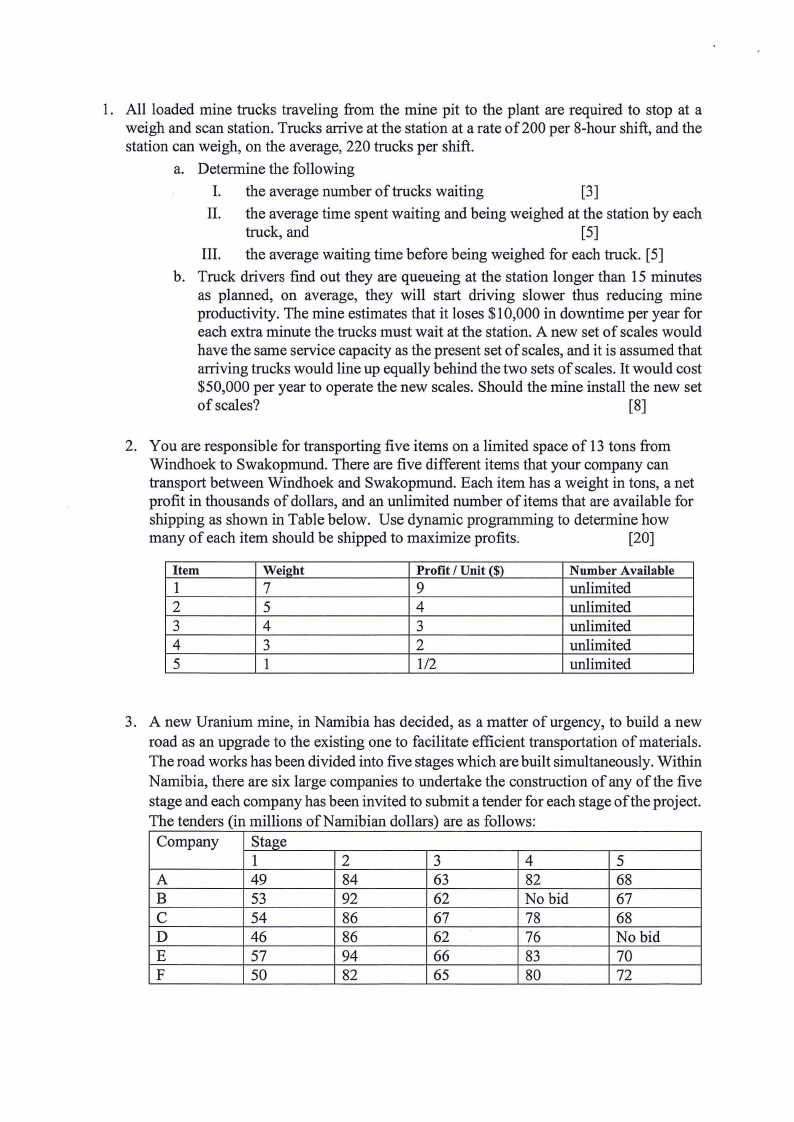

3. A new Uranium mine, in Namibia has decided, as a matter of urgency, to build a new

road as an upgrade to the existing one to facilitate efficient transportation of materials.

The road works has been divided into five stages which are built simultaneously. Within

Namibia, there are six large companies to undertake the construction of any of the five

stage and each company has been invited to submit a tender for each stage of the project.

The tenders (in millions of Namibian dollars) are as follows:

Company Stage

1

2

3

4

5

A

49

84

63

82

68

B

53

92

62

No bid

67

C

54

86

67

78

68

D

46

86

62

76

No bid

E

57

94

66

83

70

F

50

82

65

80

72

|

3 Page 3 |

▲back to top |

a. Assuming that none of the companies is large enough to undertake the work of

more than one stage, advise the mine how the five contracts should be allocated.

What is the minimum total cost for the project?

[10]

b. The mine is installing power lines to different areas on the mine. The mine wants

to minimize the total length of the power line. The network of all positions

requiring electricity is shown below with the associated distances between all

points. Recommend how to best connect all the positions in the network. [10]

c. Discuss three network models that can be used to resolve some of the mining

challenges and give examples of how you can apply them in mining.

[6]

4. Show that the average inventory of an inventory model with backorder is:

Average inventory= (Q-S)2/2Q

[10]

b. Patterson Electronics supplies your mine with micro processors for your processing

plant. Currently, Patterson orders components from various suppliers. One of the

components is ordered in batches of 150 units. It has been estimated that annual

demand for these components is 250. Furthermore, carrying cost is estimated to be $1

per unit per year. For the order policy to be optimal, determine what the ordering cost

would have to be.

[5]

c. Flemming Accessories produces paper slicers used in offices and art stores. The

mini slicer has been one of the most popular items: Annual demand is 6750 units. The

company produces the mini slicers in batches. On average the company can

manufacture 125 units per day. Demand for these slicers during the production

process is 30 per day. The set up cost for the equipment necessary to produce the mini

slicers is $150. Carrying costs are $1 per mini slicer per year. How many mini slicers

should the company manufacture in each batch?

[4]

|

4 Page 4 |

▲back to top |

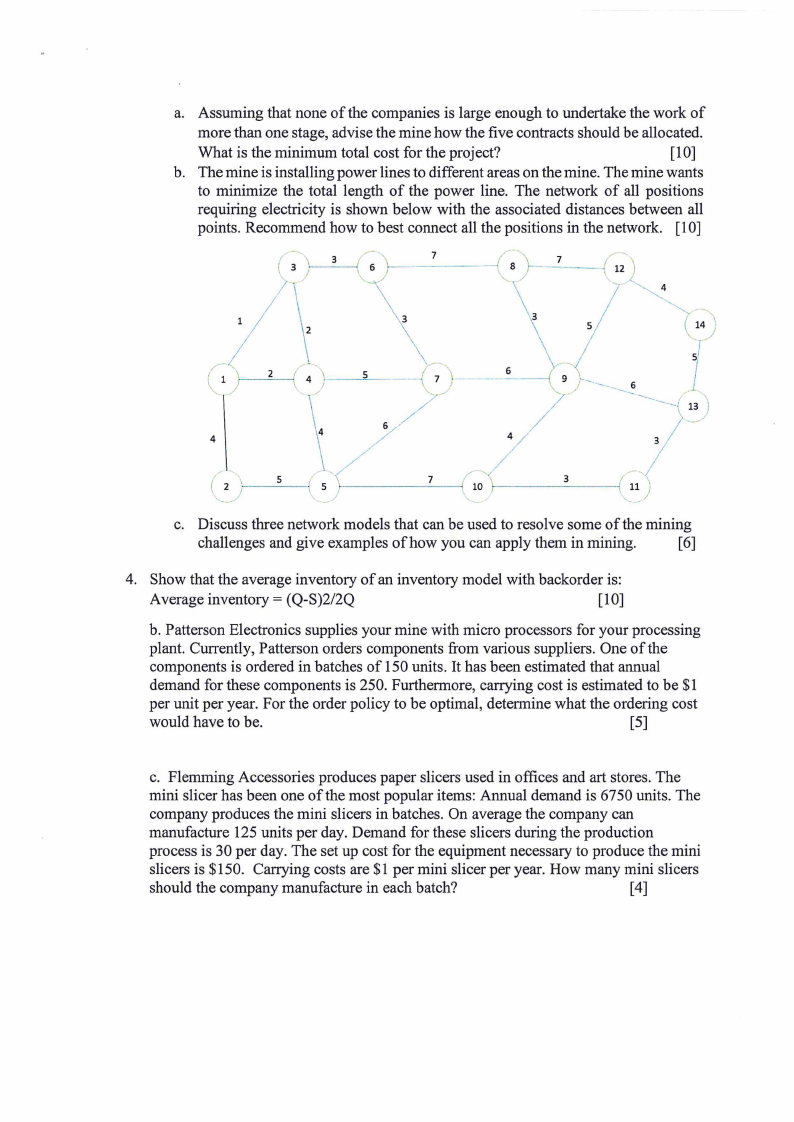

5. The following details pertain to a job, and indirect cost for the project is N$ 1100 per day.

Scheduled the project to optimal cost.

Job Predecessor

Normal

Crash

Time in hrs Cost in N$ Time in hrs Cost in N$

A

-

B

C

C

-

D

A,B

E

C

F

D

G

E,F

H

D

3

1400

2

2100

6

2150

5

2750

2

1600

1

2400

4

1300

3

1800

2

1700

1

2500

7

1650

4

2850

4

2100

3

2900

3

1100

2

1800

a. Draw the network diagram and determine the project completion time? [7]

b. What is the total cost of the project?

[1]

c. Given that the project has been given a deadline by management, to what extent

can the project be crashed and what is the corresponding cost? [7]

End of Exam

|

5 Page 5 |

▲back to top |

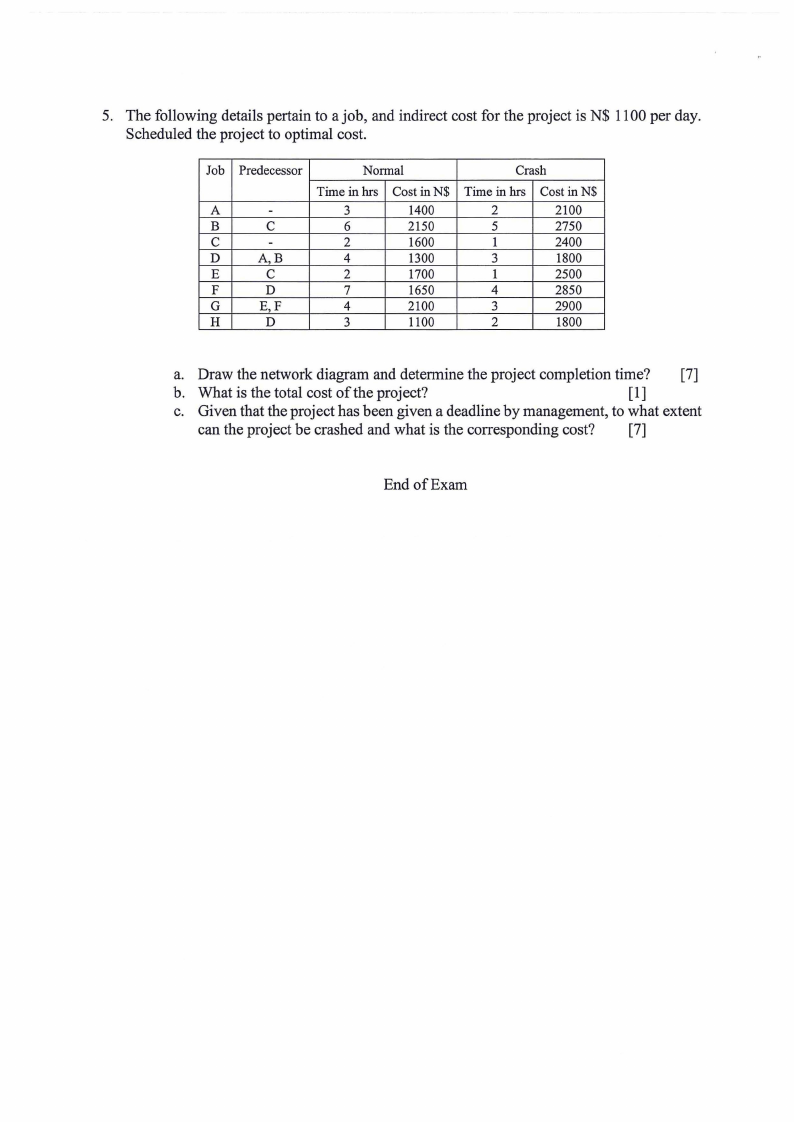

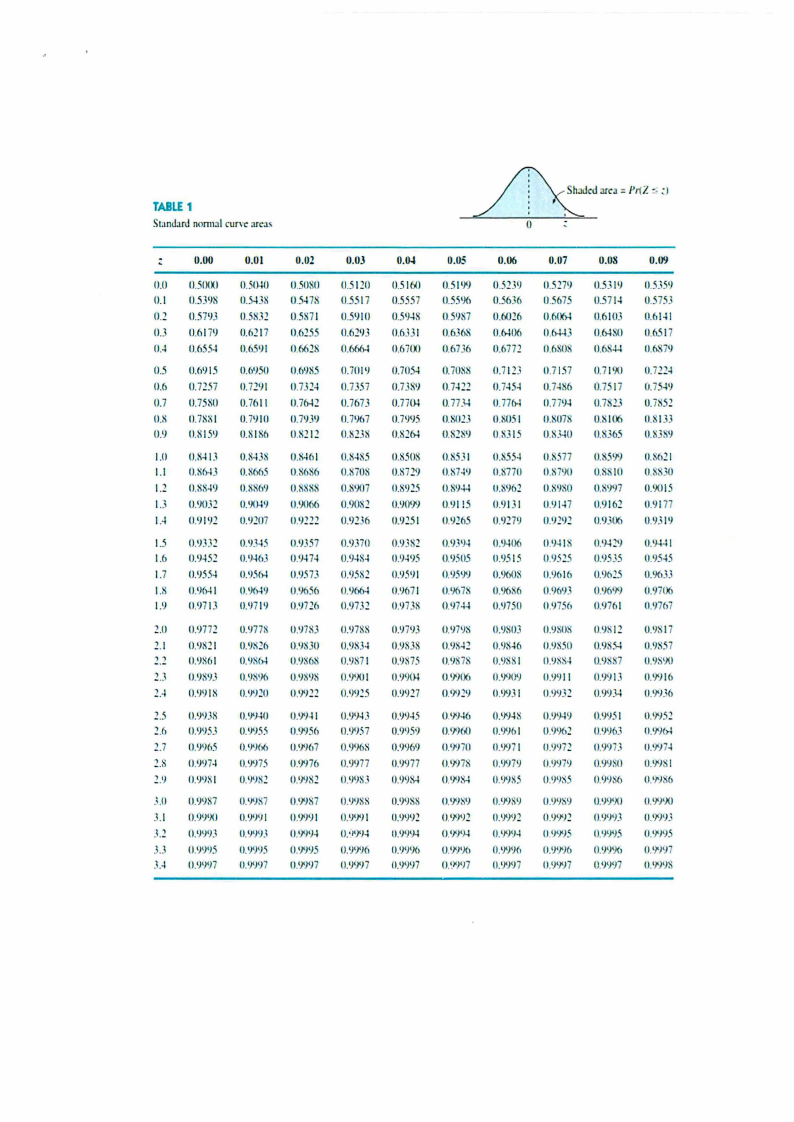

TABLE1

Stan<l:irdnonn:ilcun-c arc:i.~

~kd

=,a P,fl., cl

'

0

'

0.00

0.01

0.0:? 0.03

o.~ 0.05

0.06

0.07

o.os 0.09

0.0 0.5000 0.50-IO 0.5080 0.5120 0.5160 0.51'19 0.5231) U.5279 0.5319 0.5359

0.1 ll.5398 ll.5-138 U.5478 0.5517 0.5557 0.55% 0.5636 ll.56 5 0.5714 0.575'

0.2 0.571)

0.5:m 0.5!i71 0.5•JI0 0.5948 U.5987 0.6026 0.60M 0.6103 0.6141

0.3 0.617') 0.6217 0.6255 0.6293 0.6331 0.6'68 0.6-106 0.6+13 0.6-180 0.6517

0.655-1 0.6591 0.6628 0.6664 0.6700 0.67 6 0.6772 0.6S0S ll.6'+l 0.6S7')

0.5 0.61)1.5 0.61)50 0.6%5 ll.7011J 0.7054 0.70SS U.712' 0.7157 0.7l9o

0.6 0.7257 0.7291 0.7 24 0.7357 0.7381) U.7422 0.7454 0.7-l.6 0.7517 0.7549

0.7 0.7580 0.761l U.76-12 0.7673 ()_77(}.l 0.773-l 0.776-1 0.7794 0.7823 0.7S52

0.X ll.7881

0.9 0.8159

0.7910

0.SI '6

0.7<J13J

0.8212

0.7'J67

0.82'8

0.7995 0.8023

O.!L6-I 0.;'281)

0.8051

U.S 15

0.S07S 0.SI~

0. 3-10 0. 365

0.81'3

0..'J '<J

1.0 lUi413 0.S.1'S U.S46I 0.!i4'5 0.8508 0.8531 0.8554 ll.!i577 0. '599 U.,'6_1

I.I 0.XMJ lUl665 0.S6S6 0.S70S U.8729 0..'74') o.:mo 0.S790 U.S,'10 O.,'I"')

1.2 0.!i849 0.S!i61J o.sss. 0.89()7 ll.SIJ25 llS944 lUl%2 0.S9S0 0.,'997 0.9015

1.3 0.9032 0.

o.•J(Ki6 0.90S2 0.'J()<)<J U.91!5 0.9131 0.')147 0.')16_ 0.91?7

IA 0.9192 0.9207 ll.9222 0.92'6 ll.9251 ll.9265 ll.9279 O.'J2lJ2 0.9306 U.9.il'J

1.5 0.'JJ:2 o.•J~4.5 0.1J357 0.9'70 0.9 .'2 0.9'94 0.9406 ll.94IS 0.9-112) 0.'1441

1.6 0.9452 0.946 0.9474 o.94S4 U.9495 0.9505 ll.9515 U.952 0.9535 0.9545

1.7 0.9554 0.956-1 U.9573 U.9'S2 0.')591 0.959') 0.960,' U.9616 ()_96_5 U.963'

l.!i ll.1)6-1l 0.9M9 0.%56 0.9664 0.%71 U.967.' 0.%,'6 U.969' 0.%r.,<J 0.9 06

1.9 o.•m3 0.IJ711J 0.9726 0.9732 0.'>73S 0.'J7+l 0.9750 0.97. 6 0.97(11 0.976

2.0 lJ.9772 0.9778 lJ.97S' 0.97SS 0.'J7'J3 ll.979S 0.9S0J 0.9 '0' U.'J,12 0.9.'l7

2.1 0.'Jli21 o.•J,_6 ll.9S'lJ 0.9S34 0.'JSJS 0.'J!i-12 ll.9S46 0.9S5lJ U.'J'>1 0.98.57

2.2 0.9li6I 0.9S6-I U.9X6S 0.9S71 0.9875 0.9'7.' 0.9.'Sl ll.9S:4 0.9 '8

lJ.9 'I}()

2.J ll.9S9J 0.'J:i'.16 U.9S1JS 0.9901 0.')9()4 0.')')()6 0_<)')()9 U.9911 0.')913 ll.'JJl6

2.4 0.'J9IS ()_l)'}_l) 0.9922 0.')')25 U.'J927 0.')<2J9 0.9931 lJ.'J<J3_ 0.91J34 0.')<)36

2.5 0.'NJ,

o.•./')41 0.')')43 0.')9-15 0.1JH6 0.'JHS 0.')1.>49 0.')')51 0.IJ<J-

2.6 0.995 ll.9'J55 0.9956 ll.'J'J57 ll.9959 U.'N60 ll.'JJ61 0!J'J62 U.9963 0.9%-l

_.7 0.9%5 0.'JJM U1.JJ67 0.'J'J6!i 0.1J969 (}_l)'}i() 0.'./'J7l 0.')972 0.99 J lJ.')<J4

2.!i 0.'JIJ74 0.9'J75 lJ.9'J76 0.9977 0.')977 0.9978 0.')'J79 lJ.99 9 lJ.99.'0 0.99 'I

2.9 0.99Sl 0.9'nL 0.'JJS2 ll.1JIJS' lJ.'J9S-l 0.'.l'JS-l ll.9'JS5 U.91J,'5 0.99S6 lJ.')'J'6

J.0 U.99S7 0.9'J.'7 0.'.1')87 ll.9'J.'S 0.')9SS lJ.')IJ,'1) ll.'.l'JS1J 0.1)9.'9 U.9990 lJ.9')1)()

.I

0.91)1)()

0.')')91 ll.'.l'J9I 0.')')'JI U.99'J2 (J_')l)'J2 0.9')92

0.')')')2 U.91)')3 U.'.1993

J.2 0.99'J.I 0.9')9.1 0.'JJ1H 0.'11)1).j 0.')9114 0.9'J'J4 0.9')94 ll.99'J5 0.'JW5 0.'J<J95

3.' 0.1J91J. 0.1J<1J5 0.'JJ95 ll.')')'J6 0.91)96 U.99% 0.'.1')% ll.9'JJ6 0.9996 ()_<)<J97

3.4 l).')')')7

LJ.'JJ97 ll.9'J'J7 ().')')')7

0.'J91J7 (J_\\)(J<J7 ll.'.l'J•)7 0.')')')7 0.'J9'J7 0.999.'

|

6 Page 6 |

▲back to top |

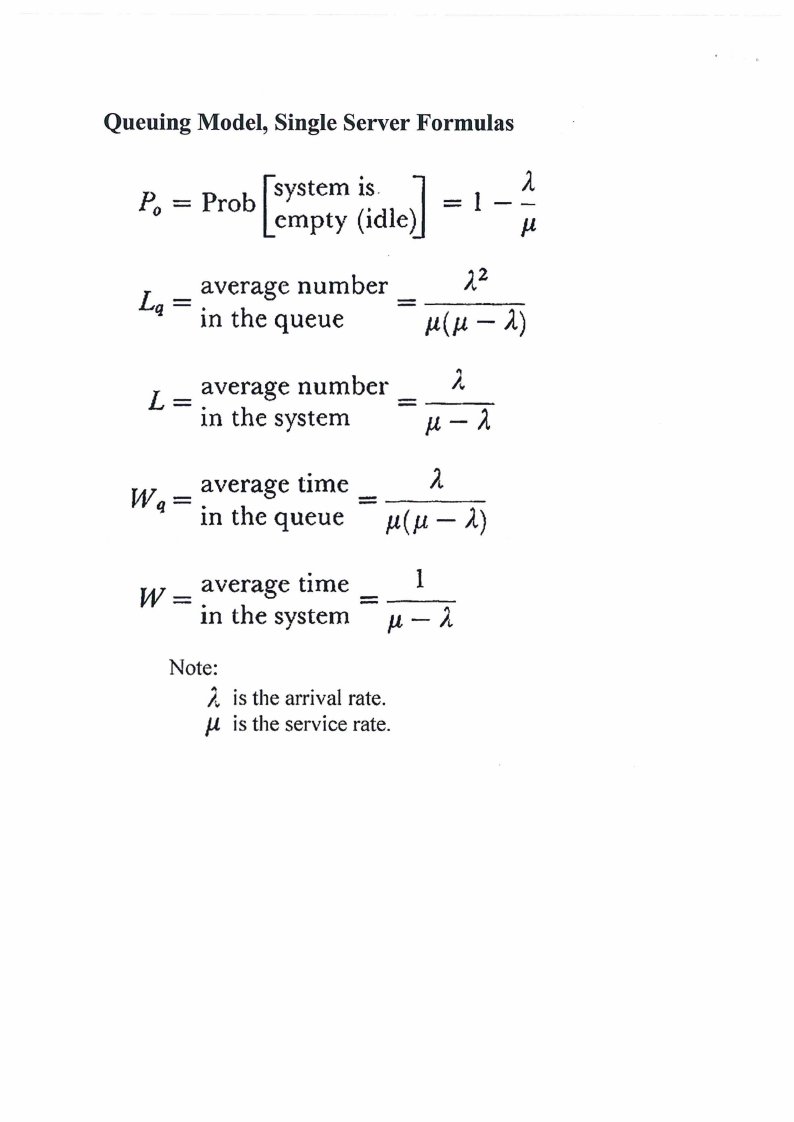

Queuing Model, Single Server Formulas

J p0

=

Prob

[system

empty

i~.

(idle)

=I- A

µ

L = average number

q in the queue

µ(µ - A)

L = average number = /4

in the system

µ- A

W = average time=

A

4 in the queue µ(µ - A)

W = average time = I

in the system µ - }"

Note:

)1, is the arrival rate.

µ is the service rate.