|

ORC711S - Operations Research - 1st Opp - June 2023 |

|

1 Page 1 |

▲back to top |

nAm I BIA unlVERSITY

OF SCIEnCE AnD TECHn OLOGY

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENTOF Civil, Mining and Process Engineering

QUALIFICATION : Bachelors of Engineering in Mining Engineering

QUALIFICATION CODE: 08BMEG

LEVEL: 7

COURSECODE: ORC711S

COURSENAME: OPERATIONSRESEARCH

SESSION: JUNE 2023

DURATION: 3 HOURS

PAPER: THEORY

MARKS: 100

EXAMINER(S)

MODERATOR:

SECONDOPPORTUNITYQUESTION PAPER

Dr Lawrence Madziwa

Prof Mallikarjun Rao Pillalamarry

INSTRUCTIONS

1. Answer all questions.

2. Read all the questions carefully before answering.

3. Marks for each questions are indicated at the end of each question.

4. Please ensure that your writing is legible, neat and presentable.

PERMISSIBLEMATERIALS

1. Examination paper.

THIS QUESTION PAPER CONSISTS OF 7 PAGES (Including this front page)

|

2 Page 2 |

▲back to top |

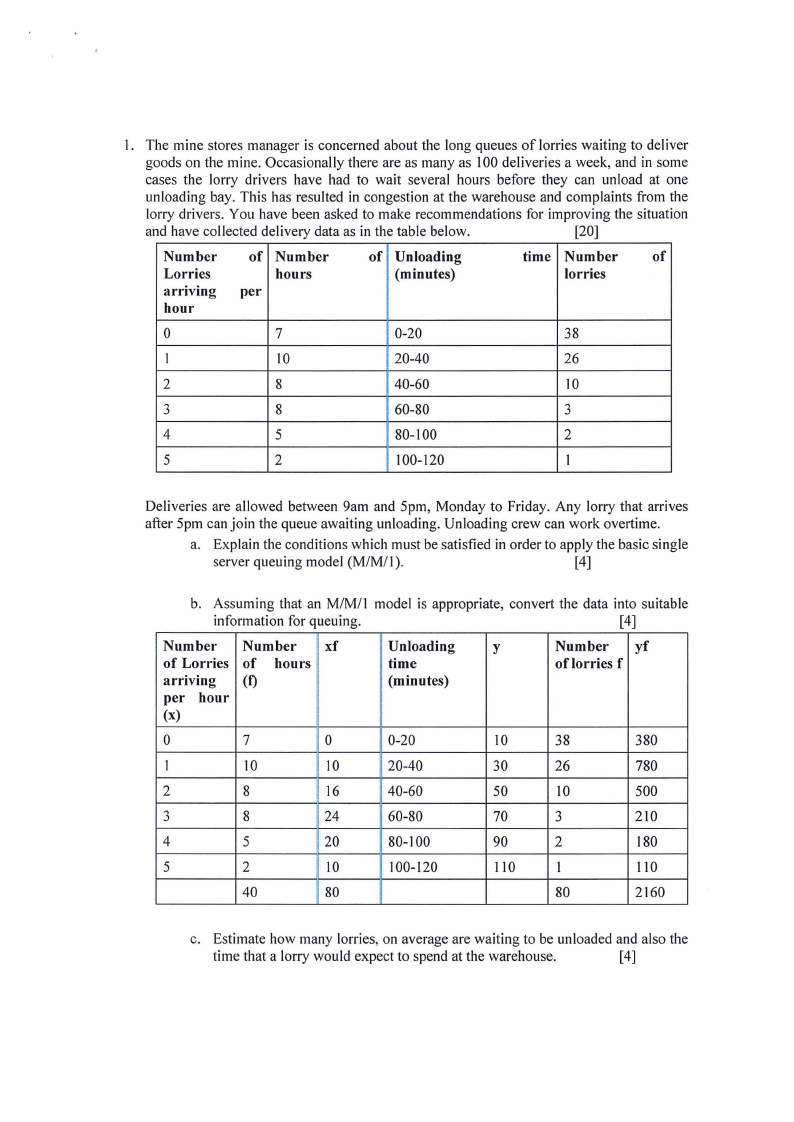

I. The mine stores manager is concerned about the long queues of lorries waiting to deliver

goods on the mine. Occasionally there are as many as I 00 deliveries a week, and in some

cases the lorry drivers have had to wait several hours before they can unload at one

unloading bay. This has resulted in congestion at the warehouse and complaints from the

lorry drivers. You have been asked to make recommendations for improving the situation

and have collected delivery data as in the table below.

[20]

Number

Lorries

arriving

hour

of Number

hours

per

of Unloading

(minutes)

time Number

of

lorries

0

7

0-20

38

I

10

20-40

26

2

8

40-60

10

3

8

60-80

3

4

5

80-100

2

5

2

100-120

I

Deliveries are allowed between 9am and 5pm, Monday to Friday. Any lorry that arrives

after 5pm can join the queue awaiting unloading. Unloading crew can work overtime.

a. Explain the conditions which must be satisfied in order to apply the basic single

server queuing model (M/M/1).

[4]

b. Assuming that an M/M/1 model is appropriate, convert the data into suitable

information for queuing.

[4]

Number Number xf

of Lorries of hours

arriving (t)

per hour

(x)

Unloading

y

time

(minutes)

Number yf

of lorries f

0

7

0

0-20

10

38

380

I

10

10

20-40

30

26

780

2

8

16

40-60

50

10

500

3

8

24

60-80

70

3

210

4

5

20

80-100

90

2

180

5

2

10

100-120

110

l

110

40

80

80

2160

c. Estimate how many lorries, on average are waiting to be unloaded and also the

time that a lorry would expect to spend at the warehouse.

[4]

|

3 Page 3 |

▲back to top |

d. The unloading bay is currently staffed by two employees who are each paid

$100 for a 40 hour week, with any overtime being paid at a 4/3 rate. A

suggestion has been made that a third person should be employed in the

unloading ay which, it has been estimated, would result in saving of seven

minutes in the average time to unload a lorry. This, it has been claimed, would

not only reduce the lorry waiting time but would also produce a saving in cost

to the mine. Analyse this suggestion and make a recommendation. [8]

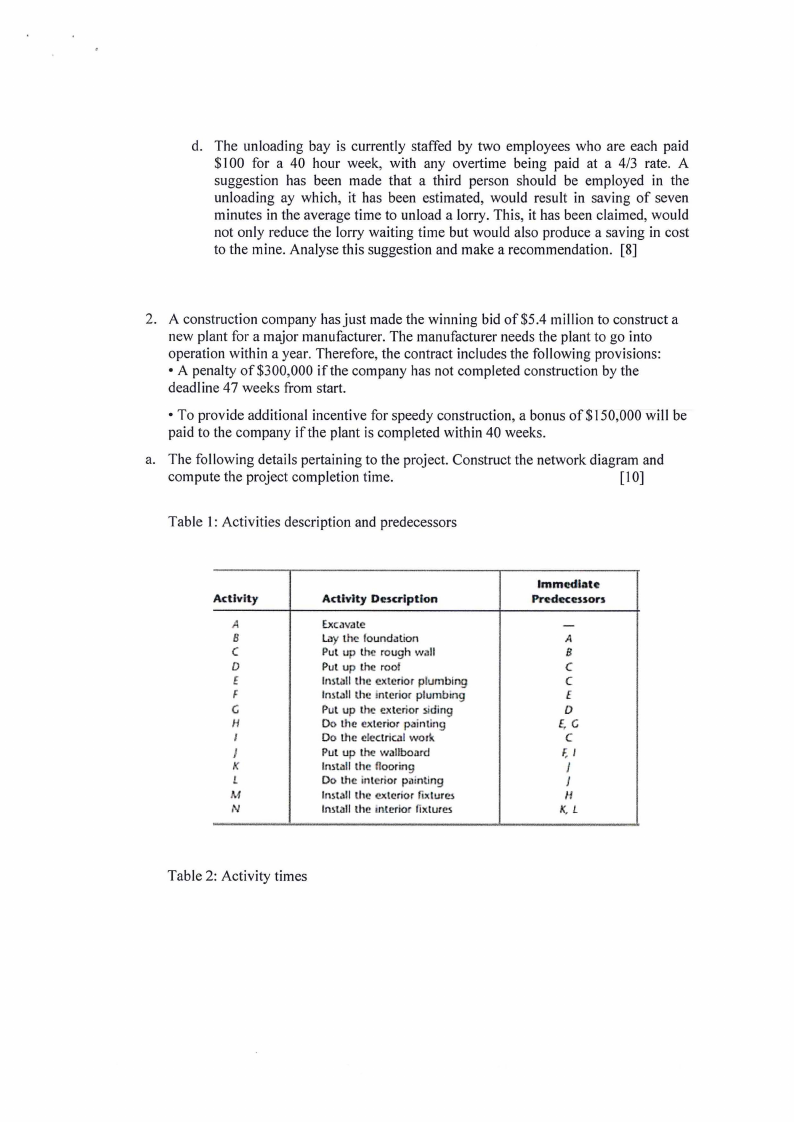

2. A construction company has just made the winning bid of $5.4 million to construct a

new plant for a major manufacturer. The manufacturer needs the plant to go into

operation within a year. Therefore, the contract includes the following provisions:

• A penalty of $300,000 if the company has not completed construction by the

deadline 47 weeks from start.

• To provide additional incentive for speedy construction, a bonus of $150,000 will be

paid to the company if the plant is completed within 40 weeks.

a. The following details pertaining to the project. Construct the network diagram and

compute the project completion time.

[ 10]

Table 1: Activities description and predecessors

AcUvlty

A

B

C

D

t

F

G

H

I

J

K

L

M

N

Activity Description

E.xc.:ivate

L'ly the foundntion

Pul up th rough willl

Put up the roof

IIHUlllthe cxtcr or plumbing

lrulllll thl! interior plumbing

Pul up the e,,cterior .siding

Do the exterior pciintlng

Do th<?electrical work

Put up the wallboa.rd

!mt.ill the flooring

Do the intimor pilintlng

IIHtall the cxterlor fllCtur~

!rut.all the mtcrlor fixtures

lmmC?dlate

Pr~CCC!SSOrs

-

A

8

C

C

E

D

E, C

C

F, l

J

1

H

K, L

Table 2: Activity times

|

4 Page 4 |

▲back to top |

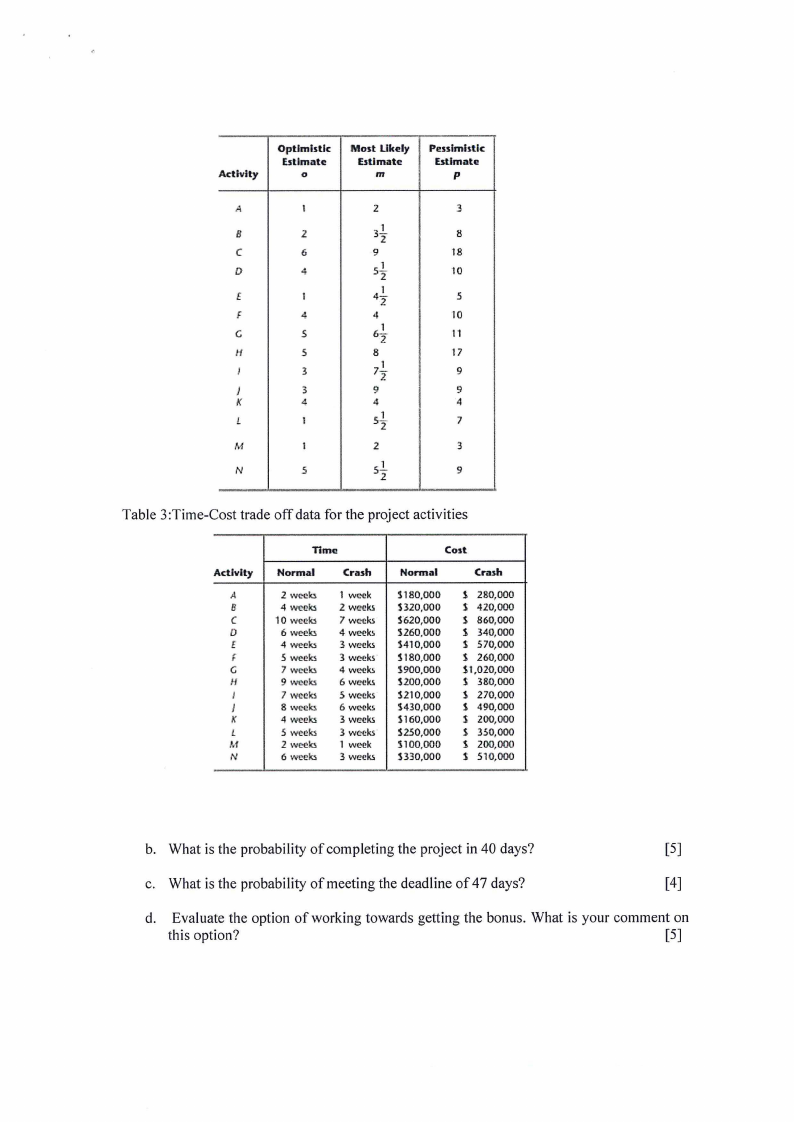

Activity

Optimistic

Estimate

0

Most Likely

Estimate

m

Pessimistic

Estimate

p

A

I

8

2

C

6

D

4

f

I

f

4

G

5

H

5

I

3

J

3

K

4

L

I

M

I

N

5

2

3

3l

2

8

9

18

sl

2

10

4..!..

2

5

4

-io

6..!..

2

11

8

17

7..!..

2

9

9

9

4

4

sl2

7

2

3

sl

2

9

Table 3 :Time-Cost trade off data for the project activities

Activity

A

8

C

D

E

f

G

H

I

J

I<

L

M

N

Time

Cost

Normal

Crash

Normal

Crash

2 weeks

4 weeks

10 Wet!k5

6 wet:?!c.

4 weeks

5 week5

7 weeks

9 weeks

7 weeks

8 weeks

4 weeks

5 weeks

2 weeks

6 weeks

1 W(c'ek

2 W!!i!ks

7 weeks

4 weC?k~

3 weeks

3 weeks·

4 W(c'C!ks

6 weeks

5 weeks

6 W<.'ek5

3 weeks

3 weeks·

1 week

3 weeks

5180,000

1320,000

S620,000

'!260,000

1410,000

S180,000

$900,000

U00,000

S210,000

'!430,000

S160,000

S250,000

Sl00,000

B30,000

$ 280,000

s 420,000

s 860,000

1 340,000

s 570,000

s 260,000

1·1,020,000

s 380,000

s 270.000

1 490,000

s 200,000

s 350,000

1 200,000

s 510,000

b. What is the probability of completing the project in 40 days?

[5]

c. What is the probability of meeting the deadline of 47 days?

[4]

d. Evaluate the option of working towards getting the bonus. What is your comment on

this option?

[5]

|

5 Page 5 |

▲back to top |

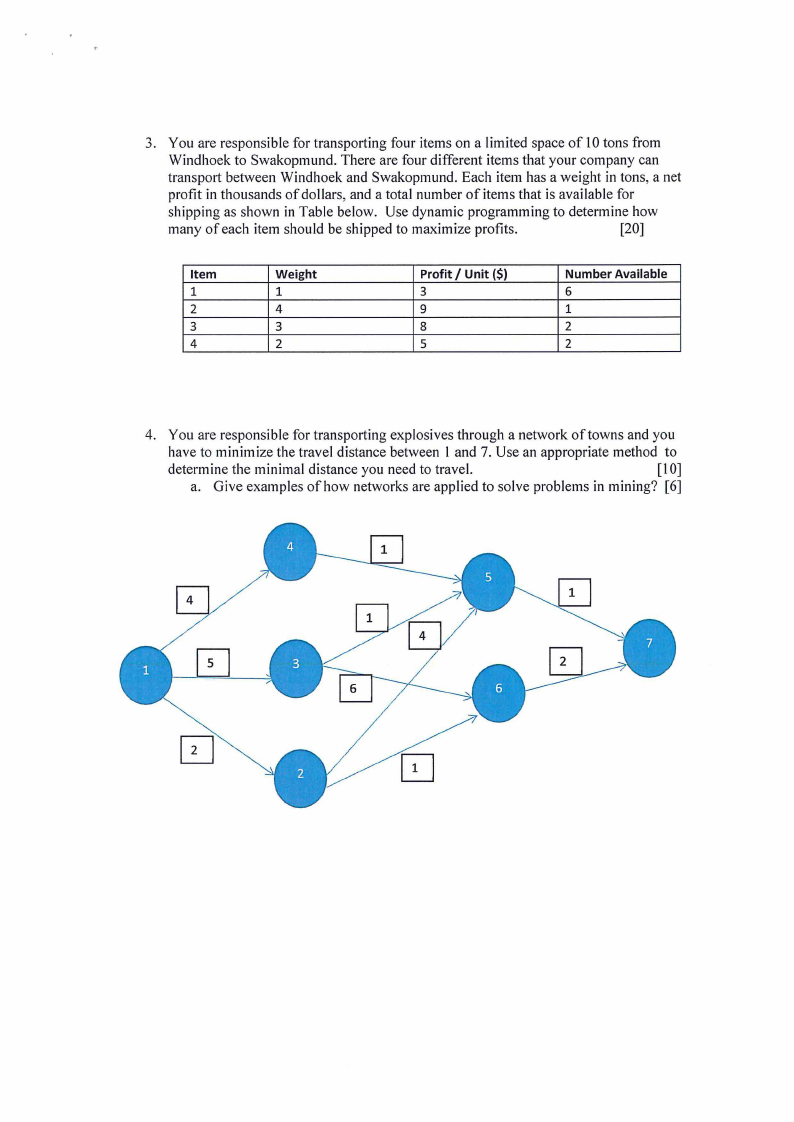

3. You are responsible for transporting four items on a limited space of 10 tons from

Windhoek to Swakopmund. There are four different items that your company can

transport between Windhoek and Swakopmund. Each item has a weight in tons, a net

profit in thousands of dollars, and a total number of items that is available for

shipping as shown in Table below. Use dynamic programming to determine how

many of each item should be shipped to maximize profits.

[20]

Item

1

2

3

4

Weight

1

4

3

2

Profit/ Unit($)

3

9

8

5

Number Available

6

1

2

2

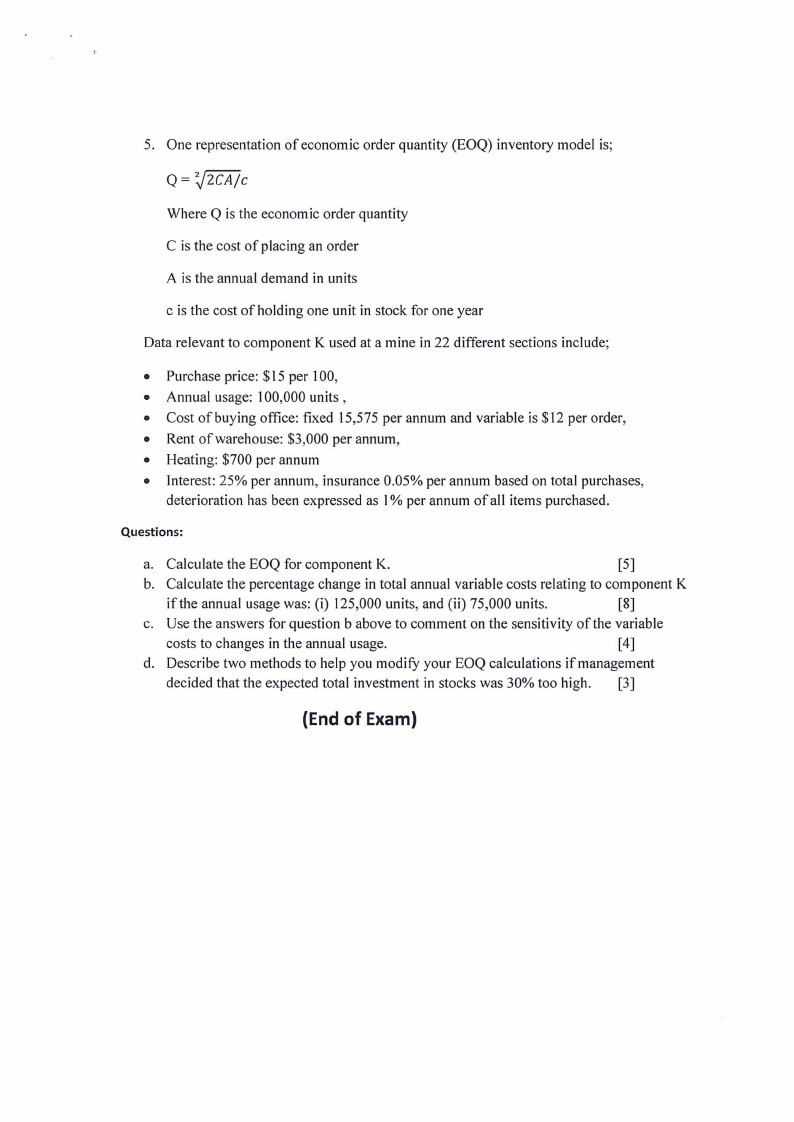

4. You are responsible for transporting explosives through a network of towns and you

have to minimize the travel distance between I and 7. Use an appropriate method to

determine the minimal distance you need to travel.

[IO]

a. Give examples of how networks are applied to solve problems in mining? [6]

|

6 Page 6 |

▲back to top |

5. One representation of economic order quantity (EOQ) inventory model is;

Q = 2.j2CA/c

Where Q is the economic order quantity

C is the cost of placing an order

A is the annual demand in units

c is the cost of holding one unit in stock for one year

Data relevant to component K used at a mine in 22 different sections include;

• Purchase price: $15 per 100,

• Annual usage: 100,000 units ,

• Cost of buying office: fixed 15,575 per annum and variable is $12 per order,

• Rent of warehouse: $3,000 per annum,

• Heating: $700 per annum

• Interest: 25% per annum, insurance 0.05% per annum based on total purchases,

deterioration has been expressed as 1% per annum of all items purchased.

Questions:

a. Calculate the EOQ for component K.

[5]

b. Calculate the percentage change in total annual variable costs relating to component K

if the annual usage was: (i) 125,000 units, and (ii) 75,000 units.

[8]

c. Use the answers for question b above to comment on the sensitivity of the variable

costs to changes in the annual usage.

[4]

d. Describe two methods to help you modify your EOQ calculations if management

decided that the expected total investment in stocks was 30% too high. [3]

(End of Exam)

|

7 Page 7 |

▲back to top |

.-l

p

= p S/i

().JI,) sA/l

Lq = (s - 1)! (Sfl - J.)

l

l

=

Lr1

+-}.

11

tq

Wq=T

w

W=~111t+-J1.l

~)s (A)k Po

p

=-----,-----;:-----1

[I;.f~ak1!

µ

]

+

1

s!

f\\µ

S/1

(S/l - A)

= ·(J./p. /l

Pn.

n!

P for n :5 ·

Q

(J/µ 11

Pn. - --I,---n,,--sp

0 for n > s